- Lean Philosophy

Eight Steps To Practical Problem Solving

The Toyota Way To Problem Solving

The art of problem solving is constantly trying to evolve and be re-branded by folks in various industries. While the new way might very well be an effective method in certain applications. A tried and true way of identifying and solving problems is the eight steps to practical problem solving developed by Toyota, years ago. The system is structured, but simple and practical enough to handle problems of the smallest nature, to the most complex issues.

Using a fundamental and strategic way to solve problems creates consistency within an organization. When you base your results off facts, experience and common sense, the results form in a rational and sustainable way.

The Eight Step Problem Solving Process

- Clarify the Problem

- Breakdown the Problem

- Set the Target

- Analyze the Root Cause

- Develop Countermeasures

- Implement Countermeasures

- Monitor Results and Process

- Standardize and Share Success

The eight steps to practical problem solving also include the Plan, Do, Check and Act (PDCA) cycle. Steps one through five are the planning process. The doing is found in step six. Step seven is the checking . Step eight involves acting out the results of the new standard.

This practical problem solving can be powerful tool to issues facing your organization. It allows organizations to have a common understanding of what defines a problem and what steps are going to be taken in order to overcome the problem efficiently.

The Eight Steps Broken Down:

Step 1: clarify the problem.

A problem can be defined in one of three ways. The first being, anything that is a deviation from the standard. The second could be the gap between the actual condition and the desired condition. With the third being an unfilled customer need.

In order to best clarify the problem, you have to see the problem with your own eyes. This gives you the details and hands-on experience that will allow you to move forward in the process.

Step 2: Breakdown the Problem

Once you’ve seen the problem first hand, you can begin to breakdown the problem into more detailed and specific problems. Remember, as you breakdown your problem you still need to see the smaller, individual problems with your own eyes. This is also a good time to study and analyze the different inputs and outputs of the process so that you can effectively prioritize your efforts. It is much more effective to manage and solve a bunch of micro-problems one at a time, rather than try and tackle a big problem with no direction.

Step 3: Set the Target

Step three is all about commitment and focus. Your attention should now turn towards focusing on what is needed to complete the project and how long it will take to finish. You should set targets that are challenging, but within limits and don’t put a strain on the organization that would hinder the improvement process.

Step 4: Analyze the Root Cause

This is a vital step when problem solving, because it will help you identify the actual factors that caused the issue in the first place. More often than not, there are multiple root causes to analyze. Make sure you are considering all potential root causes and addressing them properly. A proper root cause analysis, again involves you actually going to the cause itself instead of simply relying on reports.

Step 5: Develop Countermeasures

Once you’ve established your root causes, you can use that information to develop the countermeasures needed to remove the root causes. Your team should develop as many countermeasures needed to directly address any and all root causes. Once you’ve developed your countermeasures, you can begin to narrow them down to the most practical and effective based off your target.

Step 6: Implement Countermeasures

Now that you have developed your countermeasures and narrowed them down, it is time to see them through in a timely manner. Communication is extremely important in step six. You’ll want to seek ideas from the team and continue to work back through the PDCA cycle to ensure nothing is being missed along the way. Consider implementing one countermeasure at a time to monitor the effectiveness of each.

You will certainly make mistakes in throughout your problem solving processes, but your persistence is key, especially in step six.

Step 7: Monitor Results and Process

As mistakes happen and countermeasures fail, you need a system in place to review and modify them to get the intended result. You can also determine if the intended outcome was the result of the action of the countermeasure, or was it just a fluke? There is always room for improvement in the problem solving process, but you need to be able to recognize it when it comes to your attention.

Step 8: Standardize and Share Success

Now that you’ve encountered success along your problem solving path, it is time to set the new processes as the new standard within the organization and share them throughout the organization. It is also a good time to reflect on what you’ve learned and address any possible unresolved issues or troubles you have along the way. Ignoring unresolved issues will only lead to more problems down the road.

Finally, because you are a true Lean organization who believes continuous improvement never stops, it is time to tackle the next problem. Start the problem solving process over again and continue to work towards perfection.

Additional Resources

- 8D for Problem Solving – creativesafetysupply.com

- Training to Use 8D Problem-Solving Tactics – blog.creativesafetysupply.com

- The Great Root Cause Problem Solving Debate – realsafety.org

- Design Thinking: Empathy and Iteration for Innovation and Problem-Solving – creativesafetypublishing.com

- 10 Commandments to Continuous Improvement – lean-news.com

- Lean Manufacturing Implementation – The First 5 Steps – iecieeechallenge.org

- “No Problem” is a Problem – jakegoeslean.com

- The Transitional Steps Involved In The 5s Principles During Implementation – 5snews.com

- The Tools of Kaizen – blog.5stoday.com

Related posts:

- 3P and Lean

- The Vacation Paradox

- Why Single Minute Exchange of Die (SMED)?

- Total Quality Management And Kaizen Principles In Lean Management

- An Engaged Employee is a Productive Employee

- Jim Womack’s Top Misconceptions of the Lean Movement

- Muda, Mura, and Muri: The Three Wastes

- Find a Dealer

- MyToyota Login

- Parts & Services

- Resource Library

About Toyota

Electric forklifts.

Electric Pallet Jacks

Electric Pallet Stackers

Reach Trucks

Order Pickers

Internal Combustion: Cushion Tires

Internal Combustion: Pneumatic Tires

Heavy Duty Forklifts

Tow Tractors & Tuggers

Hand Pallet Jacks

Automated Guided Vehicles

Aerial Work Platforms

- Toyota Assist

- Smart Environment Sensor

- Rental & Used

- Find a Forklift

- Compare Forklifts

- Industry Solutions

- Automation Solutions

- Energy Solutions

- Consulting Solutions

- Financial Solutions

- Fleet Solutions

Food Storage

General Warehouse

Cold Storage

General Manufacturing

Building Materials

Automate Receiving Processes

Automate Material Transportation

Automate Storage Systems

Automate Picking Solutions

Automate Shipping Systems

Become a Greener Business

Lithium-Ion Batteries

Convert from IC to Electric

Analyze Warehouse Space

Increase Employee Education

Improve Operation Safety

Improve a Process

Toyota Commercial Finance

Financing with Toyota

MyToyota Credit Card

Benefits of Buying Toyota

Highest Quality Parts

Toyota forklift dealers are a one-stop-shop, full service forklift solutions provider.

- Model & Serial Number

- Part Number

How to Find Your Equipment Model Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

How to Find Your Equipment Serial Number

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer .

- Request a Parts Quote

- Toyota Genuine Parts

- Toyota Starlift Parts

Industry Leading Service

Increase your productivity, overall up-time and lifespan of your forklift.

- Request Service Quote

- Maintenance Plans

- 360 Support

- All Resources

- Customer Stories

- Whitepapers

- Management Guides

- Video Library

Toyota Careers

Management Team

Toyota Dealers

Sustainability

Corporate Social Responsiblity

- National Accounts

- Toyota Production System

- Forklift Safety

- Toyota Powered Engines

Press Enter to Search

Problem Solving Through Toyota Lean Management

Albert Einstein once wrote, “We cannot solve our problems with the same thinking we used when we created them.” Simply put, coming up with creative and innovative solutions to problems oftentimes requires you to look at the problem with a fresh perspective. As we’ve discussed in previous Toyota Lean Management blog posts , recognizing and cutting down on waste is critical to increasing your efficiency, reducing costs, and improving throughput. However, in order to make these improvements and see positive changes in ROI, a key step is recognizing where problems exist and working to solve them.

To recognize and solve these problems, it is often helpful to view them with a different lens to reach a newfound conclusion. Toyota’s 8 steps for problem-solving act as the lens that allows you to view different aspects of your operation from a new perspective.

Consider these eight steps as you start on the path to continuous improvement.

1. Clarify the problem

The first step in solving a problem is realizing that one exists. You can define a problem by asking yourself the following questions:

- Does my current process deviate from the standard?

- Is there a gap in my current process with what I am trying to accomplish vs. what I am accomplishing?

- Are my customer’s needs being met with my current process?

If the answer to any of these questions is no, then you know you have a problem that could use some improvement.

2. Break down the problem

Now that you’ve verified the problem, you can begin to break down the issue into smaller, more detailed pieces. It can be helpful to analyze the different inputs and outputs of your process so you can effectively see where you are currently placing your efforts. Don’t bite off more than you can chew. It is much easier to manage and solve smaller problems rather than attack one large problem with little direction.

3. Set a target

The third step is all about commitment and consistency. Now that you’ve broken down the problem, how are you going to go about solving it? How are you going to meet your new deadline, and how long will it take to complete? Allot adequate time for each activity to ensure you are giving each aspect of the project enough attention.

4. Analyze the root cause

Analyzing the root cause allows you to identify each of the factor(s) that caused a problem in the first place. Sometimes there is more than one cause, and it is important to consider each one as you work to address the issue.

5. Develop countermeasures

Establishing the root cause is only half the battle. Now, you must develop countermeasures for each of those root causes to prevent the same issues from occurring again.

6. Implement countermeasures

Now that you’ve established your countermeasures, it is time to put them into action. You may want to seek ideas from other team members to ensure you are not missing any steps. Also, it can be helpful to track how effective each countermeasure is performing along the way and making adjustments where necessary.

7. Evaluate Results and Process

The seventh step is all about implementing a system to review and evaluate how your new process is working. Countermeasures will fail, but it is important to develop an effective system that always looks for areas of improvement in order to reach the desired result.

8. Standardize Successful Processes

After receiving successful results from your previous evaluation, it is time to standardize the process within your team and the entire organization. As you work through the standardization process, continue to look for possible unresolved issues that you may have missed the first time.

Remember, the road to establishing a lean organization doesn’t stop once you improve a few processes. Lean isn’t just about identifying where you can do better; it’s about instilling a culture of respect and developing to create a workplace that your associates enjoy working in. Achieving business goals and leaner processes requires dedication and teamwork from every individual in the organization. Encourage open communication and empower your employees to bring problems to your attention when they are detected.

Related Articles

- What is Lean?

- Our Approach To Lean

- History & What We’ve Done

- Lean Research

- About Capability Development

- Login / Sign up

Sign up and join the community

Email address *

Subscribe to our newsletter

Please select all the ways you would like to hear from us Email

Your personal data will be used to support your experience throughout this website, to manage access to your account, and for other purposes described in our privacy policy .

Home > Back to Basics: Problem Solving at Toyota

Back to Basics: Problem Solving at Toyota

19th November 2014 - Lean Enterprise Academy

As Lean practitioners, we all know how to problem solve – don’t we? This is surely basic Lean stuff? Well, the answer may be that we think we do.

But often, it isn’t done well and in many cases may not fix the actual problem we set out to. In many organisations the problem solving process is rushed, focusing on finding the quickest, easiest solution rather than the one that is the most value adding. Toyota, on the other hand, uses a systematic problem solving process which carefully frames the problem, finds true root cause and uses experiments to test countermeasures to ensure the problem is fixed once and for all. This is a fundamental building block of Toyota’s success and is practised by all employees at all levels.

Toyota’s 8 Step Problem Solving

In a practice-based workshop, Mark Davies, Senior Manager at Toyota Lean Management Centre UK, took us through the 8 step problem solving process :-

1 – Clarify the problem 2 – Breakdown the problem 3 – Set a target 4 – Analyse the root cause 5 – Develop countermeasures 6 – See countermeasures through 7 – Monitor the process and results 8 – Standardise successful processes

Toyota understands that stages 1 – 4 are key to ensuring the right problem is tackled and in the right way. Problems can get messy and convoluted so it’s often confusing to teams as to which specific aspect of a problem to focus on. Step 1 and 2 are important to stratify data, often using Pareto to breakdown the problem. Asking what, when, where and who helps to highlight the top issue to be tackled. It then becomes easier to set SMART targets for improvement. Stage 4 and the identification of root cause is, arguably, the most difficult and the most poorly executed. Here Mark took us through a detailed process to move from the prioritised problem to possible direct causes. The mistakes are to jump in and prescribe possible direct causes to the problems without going to Gemba to confirm the facts. Here direct cause – observed causes of the problem – and root cause – the actual end cause we are trying to identify – are often confused. And then the use of the ‘5 whys’ , a simple tool, which is so effective in drilling down the causality chain to the true root causes.

So going through a case study to practise these steps, how did we do? Well, we didn’t get everything right! And the point here is, if we, as Lean practitioners, aren’t able to problem solve in a systematic way, how can we expect to coach and lead others to do the same?

Back to basics methinks.

An Update: Problem Solving 2021

Bringing this post up to date, we’ve developed the Lean Learning Platform so you can hone your skills. We have a range of materials to help you become self reliant on your lean journey. The complementary Level 1 Practical Problem Solving materials aim to provide knowledge around the subject area.

- Construction

- Manufacturing

- Public Sector

- Retail & Hospitality

- Supply Chain

- Capability Development

- Lean Leadership

- Lean Principles

- Management System

- Process Improvement

- Product Development

- Tools & Techniques

- Transformation

- Demand Analysis

- Flow Costing

- Lean & Green

- lean certification

- Lean Digital

- lean learning

- Lean Summit

- Lean Thinking

- Lean Transformation Framework

- Managment Routines

- People Capability

- Problem Solving

- product development

- Purpose Process People

- Rapid Problem Solving

- Standardised Work

- Supply Chain Management

- Teach Poster

- Training Within Industry (TWI)

- UK Lean Summit

- Value Stream Analysis

- Value Stream Mapping (VSM)

- Value Streams

- Visual Management

Lean Manufacturing and Six Sigma Definitions

Glossary terms, history, people and definitions about Lean and Six Sigma

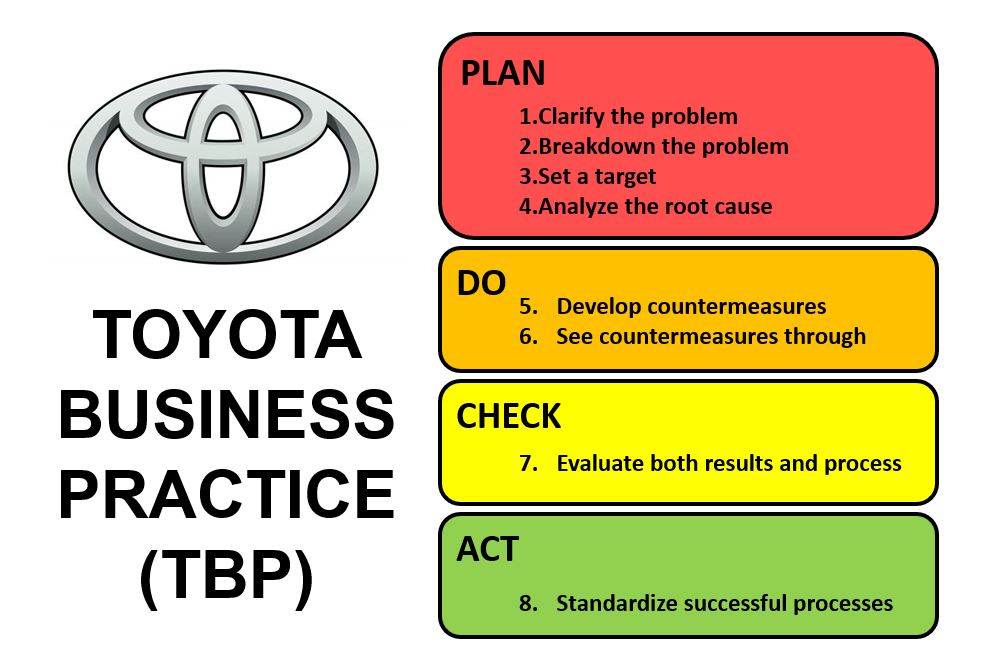

Toyota Business Practice (TBP)

TBP is Toyota’s problem solving process, based on the original Plan Do Check Act ( PDCA ) model, but more detailed and prescriptive with 8 steps instead of 4.

Toyota had originally developed The Toyota Way 2001, and wanted a way to put those principles into action across the organization and with their suppliers and partners.

The 8 steps are as follows:

- Clarify the problem

- Breakdown the problem

- Set a target

- Analyze the root cause

- Develop countermeasures

- See countermeasures through

- Evaluate both results and process

- Standardize successful processes

A3 documentation is used to capture the status of a problem within these 8 steps, so there is a natural connection between A3 , PDCA , Kata and TBP.

- What is Lean Leadership and How Do You Get it? by Jeffrey Liker

- The Toyota Business Practice – Gemba Academy

- The Toyota Engagement Equation

- Extreme Toyota

- Managing to Learn: Using the A3 Management Process to Solve Problems, Gain Agreement, Mentor and Lead

Additional Resources

- FOCUS-PDCA – creativesafetysupply.com

- Eight Steps To Practical Problem Solving – kaizen -news.com

- Why You’re Still A Lean Student – Using Lean Practice Routines to Avoid Common Growth Stunting – blog.creativesafetysupply.com

- The Toyota Production System House – blog.5stoday.com

- Why Ask Why? – lean -news.com

- Another Recall For Toyota – 5snews.com

- Continuous Improvement Applied to Safety at Toyota – iecieeechallenge.org

- The Concepts of Kaizen – creativesafetypublishing.com

- 5 Kaizen Tools to Start Using – hiplogic.com

8 Steps to Problem Solving: Implement Continuous Improvement in Your Organization

The 8 Steps to Problem Solving Method was developed by Toyota Motor Corporation as a practical, structured, and simple way to handle any problem from the smallest issue to the most complex roadblock.

What is the 8 Step Problem Solving Method?

This problem-solving method helps teams identify and solve problems in a clear and structured way, ensuring that there is consistency within an organization.

This process is an expansion of the Plan, Do, Check, and Act (PDCA) cycle. Steps one through five are part of the planning process, step six is the doing process, step seven is the checking process, and step eight is the acting part of the cycle.

Following this method ensures that your problem-solving technique can be repeated in a sustainable way with the least amount of impact on your customers.

What are the benefits of the 8 Step Method?

There are a few key benefits to using this method to solve your problems:

You get to the root cause of the issue, ensuring the problem is not repeated in the future.

You can better identify and prevent any weak points in your process.

Long-term, effective solutions are generated.

Problems will be reduced over time, increasing your bottom line.

What are the 8 Steps in this Methodology?

Clarify Problem

Break Down Problem

Root Cause Analysis

Develop Countermeasures

See Countermeasures Through

Monitor Results and Processes

Standardize Successful Process

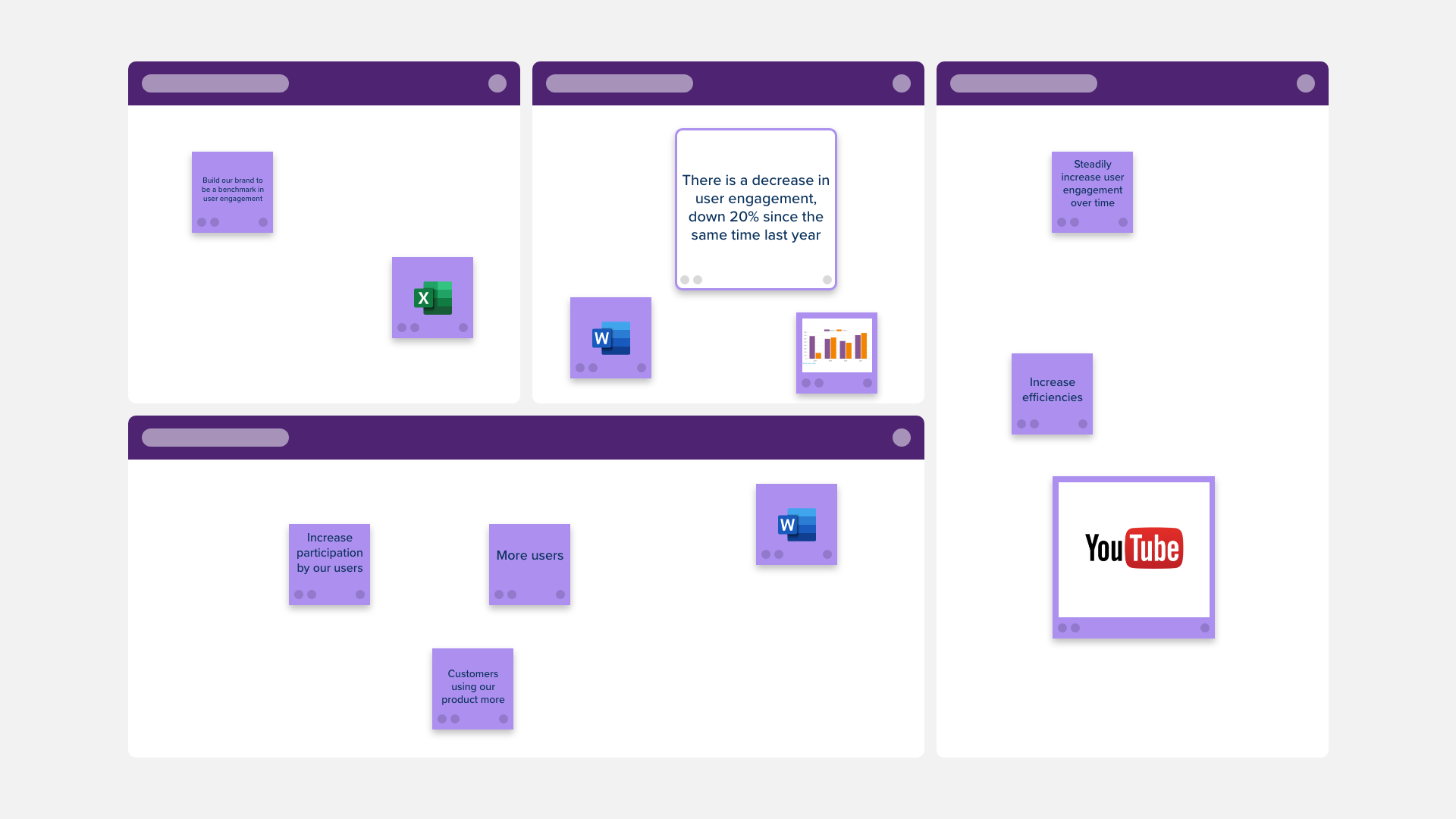

A Detailed look at the 8 Steps to Problem Solving Templates

Step 1: Clarify The Problem

In this step, you need to identify and clarify the problem. Determine why it is a problem, what should be happening instead, and how it fits into the business as a whole.

The Stormboard Template for this step is divided into four sections: Clarify Ideal Situation, Clarify Current Situation, Visualize Gap Between Current and Ideal Situations, and Set Ultimate Goal.

Step 2: Break Down The Problem

For this next step, you need to start getting more detailed and specific. Break down the problem into manageable pieces, go see the problem in the process, analyze the issues, and start thinking about priorities.

The Stormboard Template for this step is divided into three sections: Get Your Boots On and Go See, Create a Process Flow, and Identify Point of Occurrence.

Step 3: Set Your Target

This step is where you set clear target dates to resolve the problem. Determine what is needed to reach the target and how long it will take.

The Stormboard Template for this step is divided into three sections: Measurability, Target Point of Occurrence, and What, How Much, and When.

Step 4: Perform a Root Cause Analysis

In this step, you really dig into the factors that are causing the problem. Consider and address all of the causes of the issue — there will usually be more than one.

The Stormboard Template for this step is divided into four sections: Create a Decision-Making Tree, Analyse and Discard Ideas, Ask Why, and Conduct “Why Analysis”.

Step 5: Develop Countermeasures

Use this step to brainstorm countermeasures that will help you remove the root causes of your problem. Come up with as many as possible, and then narrow the criteria matrix and create an implementation plan

The Stormboard Template for this step is divided into three sections: List Root Cause, List Countermeasures, and Chart and Rate Countermeasures.

Step 6: See Countermeasures Through

In this step, you will implement your countermeasures using a clear plan and share the progress of each countermeasure that you implement with your team.

The Stormboard Template for this step is divided into three sections: Implement Countermeasures, Share progress, and Next Steps.

Step 7: Monitor Results and Processes

Use this step to determine if your countermeasures were successful or if they need to be adjusted and reimplemented.

The Stormboard Template for this step is divided into three sections: Evaluate Results, Report, and Lessons Learned.

Step 8: Standardize The Successful Process

In this step, you will integrate your successful countermeasure into your process, share your results with your team, reflect on what you have learned, and make sure there are no unaddressed issues.

The Stormboard Template for this step is divided into three sections: Standardize, Share, and Start a new Kaizen.

See the template →

Are you interested in trying out Stormboard’s 8 Steps to Problem Solving Templates with your team? Sign up for a FREE trial now !

Keep reading.

By definition, the word Agile means the “ability to move with quick, easy grace.” While this is how most of us would define Agile, the term has grown over the years to have a much more diverse, broad meaning — especially in the business world.

In today's evolving work environment, creating agile teams can change the face of team building in the modern workplace. Learn more about how you can manage your agile teams easily - whether you are in office, remote, or hybrid.

Explore the hidden costs of excessive meetings in Agile environments and learn how to streamline your team's workflow for optimal productivity. Discover practical solutions to common complaints and transform your meetings into valuable assets that drive efficiency and collaboration.

Discover the latest advancements in StormAI, the industry's first augmented intelligence collaborator, with exciting updates that enhance its capabilities. Learn about the innovative features and improvements that make StormAI 2.0 a groundbreaking technology for collaborative work.

Discover the contrasting views within the Agile community regarding spilled stories (or spillover) in sprint cycles and delve into strategies adopted by different teams. Gain insights into the pros and cons of each approach to better inform your Agile methodology.

Uncover the pivotal role collaborative platforms play in facilitating a seamless transition towards sustainable energy solutions. From project management to real-time communication, explore how these tools are reshaping the landscape for utility companies amidst the push for renewable energy adoption.

Discover how groupthink poses a significant threat to innovation within agile teams, hindering the emergence of new ideas and impeding progress throughout the scrum cycle. Explore strategies for agile team management to mitigate the impact of groupthink and foster a culture of creativity and innovation.

Discover how technology enables cohesive collaboration for remote web development teams, with 4 out of 5 developers working remotely. Explore the top collaboration tools empowering seamless workflows and website building, regardless of location.

In a fast-paced business world marked by evolving customer needs and technological advancements, staying ahead demands adaptability. Discover how fostering an agile workplace culture can empower your team to innovate, collaborate, and swiftly respond to change, driving efficiency and securing a competitive edge.

Learn how DevOps is revolutionizing development and operations workflows, enhancing product delivery speed and cost-efficiency. Explore the critical role of continuous security auditing in DevOps to mitigate vulnerabilities and safeguard against threats.

Project management challenges are inevitable. Here are some common problems and how you can stay ahead of them in 2024.

How Collaborative Leadership is Changing Business

Scared of the blank page add sample content to your template to get to work faster.

Eight-Step Problem Solving

Systematic problem-solving is a core element of a True Lean™ organization. This course teaches the 8-Step problem-solving method used within Toyota at all levels and functions to practice effective continuous learning and improvement. We use a learn-by-doing format as teams will work through real problems selected within their organization and be coached through the process to achieve tangible results while developing their problem solving and critical thinking skills. Properly implemented, this systematic problem-solving approach delete: also becomes integral to the organization’s behavior habits at all levels that support the True Lean™ culture.

Designed for

Organizational Professionals at all levels and Departments

The knowledge you will gain

- Guiding Principles behind the Eight-Step methodology

- Understanding the universal application for all functions and all levels in your organization.

- The role and use of “A3 documents” separate from the problem-solving itself.

- Utilizing Eight-Step to return to a proven performance level OR advance the performance level. Both deliver tangible results.

- Application of temporary measures and long-term countermeasures to prevent recurrence and achieve sustainable improvements.

- How it engages all to “own their workplace” and drive positive moral and personal development.

Interactive with Gap Analysis “Takeaway”

- This interactive session includes dynamic learning with open discussions

- Participants will learn the 8-step process and how to write an A3 summary using real problems from their workplace.

- Participants will be able to describe the philosophy, principles, and practice of the methodology and determine their needs-based next steps

Coaching Available

- Executive and Operational Coaching for Individuals based on the organizational level

- Ongoing needs-based Coaching on Eight-Step Problem Solving

Registration Information

Location: Virtual Fee: $2500 per participant

Register Today

For information on fees for a dedicated session, contact [email protected] .

- Our Services

Practical Problem Solving

Many organisations often struggle with effective problem solving and find that the best they can achieve is to merely contain the existing problems by introducing more waste into the organisation. For example an unreliable machine will be managed by adding in more stock to protect supply to the customer or through the acquisition of a second machine to ensure throughput. Real problem solving countermeasures the root cause of an issue preventing it from reoccurring and in doing so creates stability with the least amount of waste.

Toyota A3 Problem Solving is not a skill reserved for engineers and managers, if you truly desire to harness the creativity and innovation of your employees then it should be seen as a fundamental skill possessed by everyone.

Key Study Areas

- Introduction to Toyota A3 8 step problem solving approach

- Differences between Toyota approach and other such as six sigma

- Define the real problem

- Use and present data to clarify the point of cause of the problem

- Study the problem to ensure complete understanding

- Select countermeasures and evaluate effectiveness

- Monitor the results & gain greater benefits through effective sharing

All levels of an organisation.

Problem Solving Course Information

This course can be delivered at Deeside or at a client's site. Undertaking the course at your own facility will allow for a real problem to be tackled.

This course is available in two versions:

One day version which will teach you the theory and challange you to apply your knowledge on a case study.

Two day version where, in addition to the above, we will support you to apply the principles to an area within your own organisation.

Customer Comments

"As a six sigma green belt I was sceptical about how this would compare. I was amazed at what Toyota are achieving with this approach." - 13/11/19

Search with any image

Unsupported image file format.

Image file size is too large..

Drag an image here

- Kindle Store

- Kindle eBooks

- Business & Money

| Print List Price: | $29.00 |

| Kindle Price: | $9.99 Save $19.01 (66%) | Amazon.com Services LLC |

Promotions apply when you purchase

These promotions will be applied to this item:

Some promotions may be combined; others are not eligible to be combined with other offers. For details, please see the Terms & Conditions associated with these promotions.

Buy for others

Buying and sending ebooks to others.

- Select quantity

- Buy and send eBooks

- Recipients can read on any device

These ebooks can only be redeemed by recipients in the US. Redemption links and eBooks cannot be resold.

Sorry, there was a problem.

Download the free Kindle app and start reading Kindle books instantly on your smartphone, tablet, or computer - no Kindle device required .

Read instantly on your browser with Kindle for Web.

Using your mobile phone camera - scan the code below and download the Kindle app.

Image Unavailable

- To view this video download Flash Player

Toyota's 8-Steps to Problem Solving Kindle Edition

- Print length 70 pages

- Language English

- Sticky notes On Kindle Scribe

- Publication date May 6, 2020

- File size 2330 KB

- Page Flip Enabled

- Word Wise Enabled

- Enhanced typesetting Enabled

- See all details

Customers who bought this item also bought

Product details

- ASIN : B088B77XXV

- Publication date : May 6, 2020

- Language : English

- File size : 2330 KB

- Simultaneous device usage : Unlimited

- Text-to-Speech : Enabled

- Screen Reader : Supported

- Enhanced typesetting : Enabled

- X-Ray : Not Enabled

- Word Wise : Enabled

- Sticky notes : On Kindle Scribe

- Print length : 70 pages

- #3,058 in Business Decision-Making

- #4,834 in Two-Hour Business & Money Short Reads

- #5,014 in Business Decision Making

Customer reviews

| 3 star | 0% | |

Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness.

- Sort reviews by Top reviews Most recent Top reviews

Top reviews from the United States

There was a problem filtering reviews right now. please try again later..

Top reviews from other countries

Report an issue

- About Amazon

- Investor Relations

- Amazon Devices

- Amazon Science

- Sell products on Amazon

- Sell on Amazon Business

- Sell apps on Amazon

- Become an Affiliate

- Advertise Your Products

- Self-Publish with Us

- Host an Amazon Hub

- › See More Make Money with Us

- Amazon Business Card

- Shop with Points

- Reload Your Balance

- Amazon Currency Converter

- Amazon and COVID-19

- Your Account

- Your Orders

- Shipping Rates & Policies

- Returns & Replacements

- Manage Your Content and Devices

- Amazon Assistant

- Conditions of Use

- Privacy Notice

- Consumer Health Data Privacy Disclosure

- Your Ads Privacy Choices

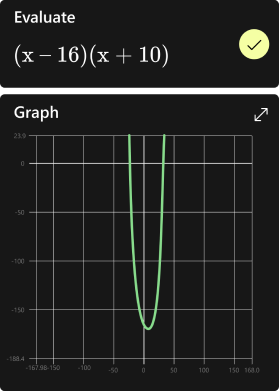

Get step-by-step solutions to your math problems

Try Math Solver

Get step-by-step explanations

Graph your math problems

Practice, practice, practice

Get math help in your language

Current time by city

For example, New York

Current time by country

For example, Japan

Time difference

For example, London

For example, Dubai

Coordinates

For example, Hong Kong

For example, Delhi

For example, Sydney

Geographic coordinates of Elektrostal, Moscow Oblast, Russia

City coordinates

Coordinates of Elektrostal in decimal degrees

Coordinates of elektrostal in degrees and decimal minutes, utm coordinates of elektrostal, geographic coordinate systems.

WGS 84 coordinate reference system is the latest revision of the World Geodetic System, which is used in mapping and navigation, including GPS satellite navigation system (the Global Positioning System).

Geographic coordinates (latitude and longitude) define a position on the Earth’s surface. Coordinates are angular units. The canonical form of latitude and longitude representation uses degrees (°), minutes (′), and seconds (″). GPS systems widely use coordinates in degrees and decimal minutes, or in decimal degrees.

Latitude varies from −90° to 90°. The latitude of the Equator is 0°; the latitude of the South Pole is −90°; the latitude of the North Pole is 90°. Positive latitude values correspond to the geographic locations north of the Equator (abbrev. N). Negative latitude values correspond to the geographic locations south of the Equator (abbrev. S).

Longitude is counted from the prime meridian ( IERS Reference Meridian for WGS 84) and varies from −180° to 180°. Positive longitude values correspond to the geographic locations east of the prime meridian (abbrev. E). Negative longitude values correspond to the geographic locations west of the prime meridian (abbrev. W).

UTM or Universal Transverse Mercator coordinate system divides the Earth’s surface into 60 longitudinal zones. The coordinates of a location within each zone are defined as a planar coordinate pair related to the intersection of the equator and the zone’s central meridian, and measured in meters.

Elevation above sea level is a measure of a geographic location’s height. We are using the global digital elevation model GTOPO30 .

Elektrostal , Moscow Oblast, Russia

- Bahasa Indonesia

- Eastern Europe

- Moscow Oblast

Elektrostal

Elektrostal Localisation : Country Russia , Oblast Moscow Oblast . Available Information : Geographical coordinates , Population, Altitude, Area, Weather and Hotel . Nearby cities and villages : Noginsk , Pavlovsky Posad and Staraya Kupavna .

Information

Find all the information of Elektrostal or click on the section of your choice in the left menu.

- Update data

| Country | |

|---|---|

| Oblast |

Elektrostal Demography

Information on the people and the population of Elektrostal.

| Elektrostal Population | 157,409 inhabitants |

|---|---|

| Elektrostal Population Density | 3,179.3 /km² (8,234.4 /sq mi) |

Elektrostal Geography

Geographic Information regarding City of Elektrostal .

| Elektrostal Geographical coordinates | Latitude: , Longitude: 55° 48′ 0″ North, 38° 27′ 0″ East |

|---|---|

| Elektrostal Area | 4,951 hectares 49.51 km² (19.12 sq mi) |

| Elektrostal Altitude | 164 m (538 ft) |

| Elektrostal Climate | Humid continental climate (Köppen climate classification: Dfb) |

Elektrostal Distance

Distance (in kilometers) between Elektrostal and the biggest cities of Russia.

Elektrostal Map

Locate simply the city of Elektrostal through the card, map and satellite image of the city.

Elektrostal Nearby cities and villages

Elektrostal Weather

Weather forecast for the next coming days and current time of Elektrostal.

Elektrostal Sunrise and sunset

Find below the times of sunrise and sunset calculated 7 days to Elektrostal.

| Day | Sunrise and sunset | Twilight | Nautical twilight | Astronomical twilight |

|---|---|---|---|---|

| 8 June | 02:43 - 11:25 - 20:07 | 01:43 - 21:07 | 01:00 - 01:00 | 01:00 - 01:00 |

| 9 June | 02:42 - 11:25 - 20:08 | 01:42 - 21:08 | 01:00 - 01:00 | 01:00 - 01:00 |

| 10 June | 02:42 - 11:25 - 20:09 | 01:41 - 21:09 | 01:00 - 01:00 | 01:00 - 01:00 |

| 11 June | 02:41 - 11:25 - 20:10 | 01:41 - 21:10 | 01:00 - 01:00 | 01:00 - 01:00 |

| 12 June | 02:41 - 11:26 - 20:11 | 01:40 - 21:11 | 01:00 - 01:00 | 01:00 - 01:00 |

| 13 June | 02:40 - 11:26 - 20:11 | 01:40 - 21:12 | 01:00 - 01:00 | 01:00 - 01:00 |

| 14 June | 02:40 - 11:26 - 20:12 | 01:39 - 21:13 | 01:00 - 01:00 | 01:00 - 01:00 |

Elektrostal Hotel

Our team has selected for you a list of hotel in Elektrostal classified by value for money. Book your hotel room at the best price.

| Located next to Noginskoye Highway in Electrostal, Apelsin Hotel offers comfortable rooms with free Wi-Fi. Free parking is available. The elegant rooms are air conditioned and feature a flat-screen satellite TV and fridge... | from | |

| Located in the green area Yamskiye Woods, 5 km from Elektrostal city centre, this hotel features a sauna and a restaurant. It offers rooms with a kitchen... | from | |

| Ekotel Bogorodsk Hotel is located in a picturesque park near Chernogolovsky Pond. It features an indoor swimming pool and a wellness centre. Free Wi-Fi and private parking are provided... | from | |

| Surrounded by 420,000 m² of parkland and overlooking Kovershi Lake, this hotel outside Moscow offers spa and fitness facilities, and a private beach area with volleyball court and loungers... | from | |

| Surrounded by green parklands, this hotel in the Moscow region features 2 restaurants, a bowling alley with bar, and several spa and fitness facilities. Moscow Ring Road is 17 km away... | from | |

Elektrostal Nearby

Below is a list of activities and point of interest in Elektrostal and its surroundings.

Elektrostal Page

| Direct link | |

|---|---|

| DB-City.com | Elektrostal /5 (2021-10-07 13:22:50) |

- Information /Russian-Federation--Moscow-Oblast--Elektrostal#info

- Demography /Russian-Federation--Moscow-Oblast--Elektrostal#demo

- Geography /Russian-Federation--Moscow-Oblast--Elektrostal#geo

- Distance /Russian-Federation--Moscow-Oblast--Elektrostal#dist1

- Map /Russian-Federation--Moscow-Oblast--Elektrostal#map

- Nearby cities and villages /Russian-Federation--Moscow-Oblast--Elektrostal#dist2

- Weather /Russian-Federation--Moscow-Oblast--Elektrostal#weather

- Sunrise and sunset /Russian-Federation--Moscow-Oblast--Elektrostal#sun

- Hotel /Russian-Federation--Moscow-Oblast--Elektrostal#hotel

- Nearby /Russian-Federation--Moscow-Oblast--Elektrostal#around

- Page /Russian-Federation--Moscow-Oblast--Elektrostal#page

- Terms of Use

- Copyright © 2024 DB-City - All rights reserved

- Change Ad Consent Do not sell my data

- Payment, billing, and the Microsoft Store

- Manage a subscription

- Turn on recurring billing

- Change subscription payment method

- Cancel a Microsoft 365 subscription

- Cancel other Microsoft subscriptions

- Manage a subscription from a third-party

- If you can't cancel

- Problems sharing a subscription

- View order history

- Shipping, costs, and delivery times

- Track your order

- Find downloads and product keys

- Find tax invoices

- Guest checkout

- Return or exchange items

- Get a refund on your subscription

- Cancel an order or pre-order

- Status of a return and refund

- Can't get a refund on apps and games

- Require approval for a family purchase

- Prevent unauthorized purchases

- Investigate a billing charge

- Report technical support scams

- Add a new payment method

- Update a payment method

- Remove a payment method

- Add mobile as a payment option

- Change Store country or region

- Microsoft and Xbox gift cards

- Redeem a gift card or code

- Check a Microsoft account balance

- Add money to a Microsoft account

- Spend money in a Microsoft account

- Limits on money in a Microsoft account

- Spend all Microsoft gift card money

- Cancel a Microsoft Store gift card

- Get trusted apps and games

- Make an in-app purchase

- In-app purchases through a 3rd party

- Get updates for apps and games

- Free Solitaire games for Windows

- Free Microsoft Mahjong

- Microsoft FreeCell for Windows

- Change purchase sign-in settings

- Troubleshoot buying from Microsoft Store

- Troubleshoot payment options

- Troubleshoot unknown charges

- Can't find or install an app

- Can't push an app or game to a device

- Fix problems with apps

- Can't find Microsoft Store app in Windows

- Microsoft Store app doesn't open

- “Unable to Complete this transaction” error

- Consumer and Regulatory Information

Fix problems with apps from Microsoft Store

If you're in Windows 11 and you're having problems with an app from Microsoft Store, consider these updates and fixes.

First, sign in to your Microsoft account . Next, work through these possible solutions in the order presented.

Make sure Windows is up to date. Select Start > Settings > Windows Update > Check for updates . If there is an available update, select Install now .

Check for updates

Make sure that your app works with Windows 11. For more info, see Your app doesn't work with Windows .

Update Microsoft Store. Select Start , then from the apps list, select Microsoft Store . In Microsoft Store, select Library > Get updates . If an update for Microsoft Store is available, it will start installing automatically.

Troubleshoot games. If you're having issues installing a game, see Troubleshoot game installations on Windows .

Repair or reset your apps. See Repair or Remove programs in Windows .

Reinstall your apps In Microsoft Store, select Library . Find the app you want to reinstall, and then select Install .

Open Microsoft Store

If you're in Windows 10 and you're having problems with an app from Microsoft Store, consider these updates and fixes.

Make sure Windows has the latest update : Select check for updates now, and then select Check for updates . Or, select the Start button, then select Settings > Update & Security > Windows Update > Check for Updates . If there is an available update, select Install now .

Make sure that your app works with Windows 10. For more info, see Your app doesn't work with Windows 10 .

Update Microsoft Store: Select the Start button, and then from the apps list, select Microsoft Store . In Microsoft Store, select See more > Downloads and updates > Get updates . If an update for Microsoft Store is available, it will start installing automatically.

Get updates

Troubleshoot games: If you're having issues installing a game, see Troubleshoot game installations on Windows 10 .

Repair or reset your apps: See Repair or Remove programs in Windows 10 .

Reinstall your apps: In Microsoft Store, select See more > My Library . Select the app you want to reinstall, and then select Install .

Run the troubleshooter: Select the Start button, and then select Settings > Update & Security > Troubleshoot , and then from the list select Windows Store apps > Run the troubleshooter.

For help troubleshooting game or app installation problems on your Xbox console, go to support.xbox.com .

If you can't find Microsoft Store, see Trouble finding Microsoft Store in Windows 10 .

If you're having trouble launching Microsoft Store, see Microsoft Store doesn't launch .

If you can launch the Microsoft Store but you are just having trouble finding or installing an app, see I can't find or install an app from Microsoft Store .

Need more help?

Contact Support

For technical support, go to Contact Microsoft Support , enter your problem and select Get Help . If you still need help, select Contact Support to be routed to the best support option.

Want more options?

Explore subscription benefits, browse training courses, learn how to secure your device, and more.

Microsoft 365 subscription benefits

Microsoft 365 training

Microsoft security

Accessibility center

Communities help you ask and answer questions, give feedback, and hear from experts with rich knowledge.

Ask the Microsoft Community

Microsoft Tech Community

Windows Insiders

Microsoft 365 Insiders

Find solutions to common problems or get help from a support agent.

Online support

Was this information helpful?

Thank you for your feedback.

Time in Elektrostal , Moscow Oblast, Russia now

The clock will update automatically if you turn on javascript in your browser..

- Tokyo 07:33

- Beijing 06:33

- Paris 00:33

- London 23:33

- New York 18:33

- Los Angeles 15:33

Time zone info for Elektrostal

- Elektrostal does not change between summer time and winter time.

- The IANA time zone identifier for Elektrostal is Europe/Moscow.

Time difference from Elektrostal

| −10 hours | −10 hours | |

| −8 hours | −8 hours | |

| −7 hours | −7 hours | |

| −7 hours | −7 hours | |

| −6 hours | −6 hours | |

| −3 hours | −3 hours | |

| −2 hours | −2 hours | |

| −2 hours | −2 hours | |

| −1 hours | −1 hours | |

| −1 hours | −1 hours | |

| −1 hours | −1 hours | |

| 0 | ||

| 0 | ||

| 0 | ||

| +1 hours | ||

| +2.5 hours | ||

| +5 hours | ||

| +5 hours | ||

| +5 hours | ||

| +6 hours | ||

| +7 hours |

Sunrise, sunset, day length and solar time for Elektrostal

- Sunrise: 03:40

- Sunset: 21:11

- Day length: 17h 31m

- Solar noon: 12:26

- The current local time in Elektrostal is 26 minutes ahead of apparent solar time.

Elektrostal on the map

- Location: Moscow Oblast, Russia

- Latitude: 55.79. Longitude: 38.46

- Population: 144,000

Best restaurants in Elektrostal

- #1 Tolsty medved - Steakhouses food

- #2 Ermitazh - European and japanese food

- #3 Pechka - European and french food

Find best places to eat in Elektrostal

- Best chinese restaurants in Elektrostal

- Best pizza restaurants in Elektrostal

- Best restaurants with desserts in Elektrostal

The 50 largest cities in Russia

COMMENTS

https://gembaacademy.com | The Gemba Academy Practical Problem Solving course explains the exact 8 step problem solving process used by these lean exemplars ...

The Toyota Way To Problem Solving. The art of problem solving is constantly trying to evolve and be re-branded by folks in various industries. While the new way might very well be an effective method in certain applications. A tried and true way of identifying and solving problems is the eight steps to practical problem solving developed by ...

Toyota's 8 steps for problem-solving act as the lens that allows you to view different aspects of your operation from a new perspective. Consider these eight steps as you start on the path to continuous improvement. 1. Clarify the problem. The first step in solving a problem is realizing that one exists. You can define a problem by asking ...

What is a Problem-Solving Funnel? Here is a close-up of the classic problem-solving funnel. You can see how the first 5 steps or the Plan phase of the Toyota Business Process map to this funnel, with steps 6 - 8 being the Do, Check, Act portion of the PDCA cycle of continuous improvement. A Deeper Understanding of the 8 Steps of TBP

Toyota's 8 Step Practical Problem Solving, Revisited. By Jon Miller Updated on March 4th, 2021. The practical problem solving steps…. It is too early to talk about solutions. It is still too early to talk about solutions. It is still too early to talk about solutions. It is still too early to talk about solutions.

The 8-Step Practical Problem Solving Process: The eight steps: Clarifying the problem and describing the current situation. Breaking down a big problem into smaller, more specific problems and studying the process. Setting a challenging yet achievable target. Analyzing the root cause.

https://GembaAcademy.com | Learn the 8 steps Practical Problem Solving methodology, lean thinking exemplars such as Toyota use to attack problems. ️ For mor...

Toyota, on the other hand, uses a systematic problem solving process which carefully frames the problem, finds true root cause and uses experiments to test countermeasures to ensure the problem is fixed once and for all. This is a fundamental building block of Toyota's success and is practised by all employees at all levels. Toyota's 8 Step ...

A Lean Frontiers webinar presented by Steve Ansuini.

Toyota Business Practice (TBP) TBP is Toyota's problem solving process, based on the original Plan Do Check Act ( PDCA) model, but more detailed and prescriptive with 8 steps instead of 4. Toyota had originally developed The Toyota Way 2001, and wanted a way to put those principles into action across the organization and with their suppliers ...

the 8 step process to effective problem solving •Apply the process to your own work situation during class discussion •Experience how the A-3 tool communicates the ... step Complete Root Cause Toyota strength-standardize 8 Step Problem Solving Process 3 . Lean Systems Program

Toyota's 8 Step "Practical Problem Solving" Process Some of the best problem solving methods are the simplest and one of those that continues to stand the test of time is Toyota's 8 step method. This method also goes by the name of "Practical Problem Solving" or "PPS" for short. In the diagram below

The 8 Steps to Problem Solving Method was developed by Toyota Motor Corporation as a practical, structured, and simple way to handle any problem from the smallest issue to the most complex roadblock. What is the 8 Step Problem Solving Method?

Systematic problem-solving is a core element of a True Lean™ organization. This course teaches the 8-Step problem-solving method used within Toyota at all levels and functions to practice effective continuous learning and improvement. We use a learn-by-doing format as teams will work through real problems selected within their organization ...

Paperback. $28.00 5 Used from $6.15 9 New from $28.00 1 Collectible from $29.99. Toyota's 8 Steps to Problem-Solving is a how to book. The content explains Toyota's methodology for problem-solving that has been proven as a very effective approach.The book not only lays out Toyota's 8 steps to problem-solving, it also describes specific ...

Toyota A3 Problem Solving is not a skill reserved for engineers and managers, if you truly desire to harness the creativity and innovation of your employees then it should be seen as a fundamental skill possessed by everyone. Key Study Areas. Introduction to Toyota A3 8 step problem solving approach

#ProblemSolving #LeanVlogWhat is Problem Solving is explained in this video by Toyota's approach.Here the transcript of the video.Toyota's 8 Step Problem Sol...

Paperback. $29.00 6 Used from $4.97 7 New from $28.63 1 Collectible from $29.99. Toyota's 8 Steps to Problem-Solving is a how to book. The content explains Toyota's methodology for problem-solving that has been proven as a very effective approach.The book not only lays out Toyota's 8 steps to problem-solving, it also describes specific ...

Problem-solving creativity combines creative ideas, such as exploring knowledge, defining problems, and comparing ideas to identify the most creative ones (van Hooijdonk et al., 2020). Several ...

Get math help in your language. Works in Spanish, Hindi, German, and more. Online math solver with free step by step solutions to algebra, calculus, and other math problems. Get help on the web or with our math app.

Lenina Ave., 40/8, Elektrostal 144005 Russia +7 495 120-35-45 + Add website + Add hours Improve this listing. See all (5) Ratings and reviews. 3.5. 17 reviews #12 of 28 Restaurants in Elektrostal. There aren't enough food, service, value or atmosphere ratings for Pekin yet. Be one of the first to write a review!

Geographic coordinates of Elektrostal, Moscow Oblast, Russia in WGS 84 coordinate system which is a standard in cartography, geodesy, and navigation, including Global Positioning System (GPS). Latitude of Elektrostal, longitude of Elektrostal, elevation above sea level of Elektrostal.

Elektrostal Geography. Geographic Information regarding City of Elektrostal. Elektrostal Geographical coordinates. Latitude: 55.8, Longitude: 38.45. 55° 48′ 0″ North, 38° 27′ 0″ East. Elektrostal Area. 4,951 hectares. 49.51 km² (19.12 sq mi) Elektrostal Altitude.

Select Start > Settings > Windows Update > Check for updates. If there is an available update, select Install now. Check for updates. Make sure that your app works with Windows 11. For more info, see Your app doesn't work with Windows. Update Microsoft Store. Select Start, then from the apps list, select Microsoft Store.

Sunset: 09:07PM. Day length: 17h 24m. Solar noon: 12:25PM. The current local time in Elektrostal is 25 minutes ahead of apparent solar time.