Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

A systematic review of empirical research on learning with 3D printing technology

2021, Journal of Computer-Assisted Learning

Although 3D printing (3DP) technology has become an increasingly popular educational tool in recent years, very little is known about the learning benefits of this technology. This systematic literature review synthesized empirical research on learning with 3DP in various educational settings, focusing on publication and study participants' characteristics, curriculum areas, research methodologies, instructional approaches, educational outcomes and benefits. A comprehensive survey of published and unpublished studies identified 78 empirical studies that met the inclusion criteria. In addition to positive effects on learning, 3DP facilitated innovative curriculum development and created opportunities for cross-disciplinary research. The findings revealed five major trends in 3DP learning: (1) prepare a new generation of engineers, (2) democratize additive manufacturing technology and production, (3) support learning using low-cost 3D printed learning aids, (4) produce assistive technologies, and (5) promote creativity and innovation. The review identifies critical gaps in the literature and offers suggestions for future research.

Related Papers

Additive Manufacturing

The emergence of additive manufacturing and 3D printing technologies is introducing industrial skills deficits and opportunities for new teaching practices in a range of subjects and educational settings. In response, research investigating these practices is emerging across a wide range of education disciplines, but often without reference to studies in other disciplines. Responding to this problem, this article synthesizes these dispersed bodies of research to provide a state-of-the-art literature review of where and how 3D printing is being used in the education system. Through investigating the application of 3D printing in schools, universities, libraries and special education settings, six use categories are identified and described: (1) to teach students about 3D printing; (2) to teach educators about 3D printing; (3) as a support technology during teaching; (4) to produce artefacts that aid learning; (5) to create assistive technologies; and (6) to support outreach activities. Although evidence can be found of 3D printing-based teaching practices in each of these six categories, implementation remains immature, and recommendations are made for future research and education policy.

Eusebio Reyero

Tod Colegrove

Rapid Prototyping technology enables the active construction of new knowledge in a way that may be a good fit for the academic library; beyond simply an opportunity to to lead the way technologically on campus, the addition of such resources may enable students and faculty to leverage the multidisciplinary skills and competencies needed to innovate and compete in today's rapidly changing environment. A brief review of the 3D printer selection process at UNR and a discussion of the current state of the 3D printer market will be covered. Is rapid prototyping a new multidisciplinary literacy poised to enable and transform learning and knowledge creation across the Sciences and Engineering on campus? The DeLaMare Science & Engineering Library is actively exploring the question; in this session the impact and reception of the library's recent introduction of multiple 3D printers and scanners will be presented, including real-life examples drawn from users' experience.

Sustainable Current Approaches in Architectural Science and Technology

Myint Swe Khine and Nagla Ali (Eds.), Integrating 3D printing into Teaching and Learning: Practitioners’ Perspective

Elena Novak

3D printing technology is a powerful learning tool that can involve students in active learning, design thinking, and problem solving. It creates opportunities for integrating science, engineering, technology and mathematics with other disciplines. In this chapter, we describe the benefits of 3D printing technology for teaching science and discuss a theoretical framework for designing 3D printing problem- and project-based learning in science followed by practical recommendations for creating 3D printing instructional units that can be integrated into a formal curriculum. In conclusion, we provide an example of a 3D printing project that was implemented with preservice elementary teachers in a science methods course.

International Journal of Art & Design Education

Marjo Virnes

International Journal of Computer Applications

Christos Drosos

Chelsea Schelly

Open-source 3D printing provides a cost efficient means of STEM education.These technologies can also empower student-driven engaged learning.Report on workshop for science educators to build 3D printers for their classes.Teacher workshop augmented with online instructional and visual tools.Results indicate transformative potential of these technologies in the classroom.3-D printing technologies have the potential to improve both Science, Technology, Engineering, and Mathematics (STEM) education and Career and Technical Education (CTE), as well as integrating these two educational emphases and providing opportunities for cross-curriculum engagement. The objective of this study is to investigate the potential of open-source (OS) technologies in an educational setting, given the combination of economic constraints affecting all educational environments and the ability of OS design to profoundly decrease the cost of technological tools and technological innovation.This paper reports on a 3-day workshop augmented with online instructional and visual tools designed for middle school and high school level educators from a wide array of disciplines (including traditional science, math, and engineering as well as computer, shop, and art). Teachers (n=22) submitted applications to participate in the workshop, the workshop was observed for both evaluation and research, teachers participated in focus groups (n=2) during the workshop in order to discuss their interest in OS 3-D printing technology and its potential role in their classrooms, and teachers completed a voluntary post-workshop survey and responded to follow-up after printers were in the classroom for one year.During the workshop teachers built 3-D printers using OS technologies that they were then able to take back to their schools and into their classrooms.Through workshops augmented with online instructional and visual tools designed to provide facilitated yet self-directed engagement with a new, relatively unknown, and relatively complex technology, paired teacher teams were able to successfully build and use RepRap 3-D printers based on OS design in just three days.Here, we discuss both what the teachers learned and what we learned from the teachers regarding the potential for educators to construct OS 3-D printing technologies as a tool of empowering and transformative education.Open-source 3-D printing technologies have the potential to improve education through a sense of empowerment resulting from active participation, as well as through cross-curriculum engagement.

Education Sciences

Khalifa Harib

Three-dimensional (3D) printing can revolutionize the way products have been designed and manufactured. This necessitates engineering graduates equipped with the knowledge and skills of 3D printing. As a result, the educational aspects of 3D printing have earned a great deal of attention. Nevertheless, to teach 3D printing in an undergraduate engineering degree program, an outcomes-oriented approach integrating engineering design, object visualization/digitization, and 3D printing domains can be used. Accordingly, this study presents a tutorial development method to teach undergraduate engineering students the knowledge and skills of 3D printing. The method integrates the abovementioned domains maintaining a hierarchy among the seven ABET-prescribed outcomes. The hierarchy organizes the outcomes into three levels (primary, secondary, and tertiary). The presented method is implemented by introducing a tutorial where a spur gear-pinion pair is designed, visualized, digitized, and 3D p...

Book Chapter

3D printing technology is an emerging educational technology that is becoming increasingly available in schools, public libraries, museums, and higher education institutions. Oftentimes, 3D printers are underutilized because instructors have a limited experience with this technology and do not know how to integrate it into curricula. This chapter describes how 3D printing technology can be (1) introduced in a science teacher preparation program as a means of engaging prospective elementary teachers in active, collaborative, problem-based learning and (2) integrated into an existing science curriculum. We designed a 3D Printing Science Project to model for prospective teachers a lesson that they could implement with their future students in the elementary science classroom. After completing the project, prospective teachers reported a moderately high usefulness and ease of use of 3D printing technology and significantly higher design thinking abilities and attitudes toward science and teaching science. An analysis of participants' project reflections, classroom discussions, and 3D printed objects provided a further insight into their collaborative design experiences.

RELATED PAPERS

International Journal of Applied Earth Observation and Geoinformation

Nontembeko Dudeni-Tlhone

International Journal of Research in Business and Social Science (2147- 4478)

Willy Muturi

ScienceAsia

Somchit Eiam-Ong

Journal of the Society of Powder Technology, Japan

Akira Ohgami

Marcos Antonio

Jurnal Biologi Tropis

Putri Alfianti Sriwinahyu

ACTA ZOOLÓGICA MEXICANA (N.S.)

Erick Alexander contreras Ruiz

Biotechnology for Biofuels

Somayeh Farzad

Nguyen-thong Dang

INSANILLAHIA AUDIA FAJAR

Nature Communications

davide giuseppe sangiovanni

Journal of Antimicrobial Chemotherapy

Mette Skriver

F1000Research

Niranjan Konduri

Russian Linguistics

Elmira Zhamaletdinova

Clara Eka Putri

Medicentro Electronica

Jorge Luis Quiros Hernandez

1比1定做aston毕业证书 阿斯顿大学毕业证学位证书样板原版一模一样

Temas em Educação: entre questões recorrentes e possibilidades

Pimenta Cultural

Blucher Engineering Proceedings

Janaina Ruffoni

Industrial Crops and Products

Berta Heinzmann

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Organizational adoption of 3D printing technology: a semisystematic literature review

Journal of Manufacturing Technology Management

ISSN : 1741-038X

Article publication date: 10 December 2020

Issue publication date: 17 December 2021

Three-dimensional (3D) printing (3DP) offers a promising value proposition across multiple manufacturing industries. Despite the variety of production benefits the technology entails, its rate of adoption is still low compared to industry forecasts. In face of this challenge, industry as well as academia requires more information and guidance. This review aims to examine the characteristics of the existing body of research on the organizational adoption of 3DP as well as its underlying theoretical concepts. The most common criteria driving adoption will be derived, such as to facilitate the managerial decision-making process. Pathways for future research will be presented.

Design/methodology/approach

This study underlies a bibliometric literature review and additionally applies content analysis to systematically investigate the existing body of research and group decision criteria along the four major pillars of strategic decision-making.

The contributions of this paper are threefold. First, the bibliometric analysis reveals interesting aspects of the existing body of research. The most prominent characteristics of the contemporary literature are reflected along descriptive indicators, such as industry, method, model, origin, research outlet or adoption drivers, thus granting relevant insights into academia and practice. Second, the most notable adoption models are carefully analyzed on their inherent attributes and their application fit for the context of organizational 3DP adoption. Findings, for instance, revealed the dominance of diffusion of innovation (DOI) across the existing body of research and divulge that this construct is generally applied in combination with user-centered decision frameworks to yield more precise results. Third, an ample range of opportunities for future research are detected and thoroughly explained. Among others, the authors identified a clear lack of information on the impact environmental variables and contingency factors exerted on the organizational adoption of 3DP. Guidance in relation to the sourcing of industry data, usage of adoption frameworks and avenues for future scientific projects is supplied.

Originality/value

This study represents the first semi-systematic literature review on the organizational adoption of 3DP. Thus, it not only offers a valuable evaluation guide for potential adopters but also determines a future research agenda.

- Decision-making

- Manufacturing technology

- Organizational change

- Additive manufacturing

- 3D printing

- Technology implementation

Ukobitz, D.V. (2021), "Organizational adoption of 3D printing technology: a semisystematic literature review", Journal of Manufacturing Technology Management , Vol. 32 No. 9, pp. 48-74. https://doi.org/10.1108/JMTM-03-2020-0087

Emerald Publishing Limited

Copyright © 2020 2020, Desiree Valeria Ukobitz

Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode 1 Department of Psychology, University of Konstanz, Konstanz, Germany 2 Department of Psychology, New York University, New York, USA 3 Institute of Psychology, Leuphana University Lüneburg, Lüneburg, Germany

1. Introduction

What is the current body of research regarding organizational adoption of 3DP in terms of descriptive indicators?

Which adoption theory and underlying decision criteria are most frequently applied for explaining organizational adoption of 3DP and what do we learn from these studies?

Where do we still lack knowledge, and therefore, which future research opportunities can be identified?

Existing literature reviews merely analyze publications on 3DP in terms of their frequency and count across different disciplines ( Gupta and Dhawan 2018 ). While the global research output in the field of 3DP amounted to 7300 papers in 2016, work examining 3DP from a management-science perspective is far more limited. Gupta and Dhawan (2018) in their assessment of 3DP research output encountered 372 publications on 3DP from the fields of business, accounting and management (2007–2016). Unfortunately, this study does not examine the underlying content in depth and as such does not generate learnings for theory and practice. Until to date, management science has not yet contemplated any review of literature on the organizational adoption of 3DP, i.e. the decision-making processes leading to 3DP adoption in firms. Knowledge on the adoption decision is yet fragmented, and unified sources of information to support the organizational decision-making process are scarce. As this area of investigation matures, the consolidation of existing knowledge on the underlying phenomenon is required more than ever. In an effort to fill this gap, this study aimed to examine the existing body of research on organizational 3DP adoption by means of a bibliometric analysis of predefined performance indicators, as well as a critical review of the theoretic constructs was employed to understand the phenomenon. Untapped opportunities of research are defined, and pathways for future studies are determined.

Until to date, the empiric evidence required to conduct a comprehensive literature review on the organizational adoption of 3DP was insufficient. However, during the last five years initial research exploring 3DP adoption through qualitative and quantities methods (e.g. Oettmeier and Hoffman, 2017 ; Schniederjans, 2017 ) evolved and granted first results on the distinct criteria affecting intrafirm adoption. Although the majority of qualitative studies employed explorative approaches to generate knowledge on this new field of research, recent work applied quantitative methods based on large empiric samples. These empiric analyses either applied firm-centered adoption models such as the technology–environment–organization (TOE) framework by Tornatzky and Fleischer (1990) (e.g. Yeh and Chen, 2018a ), the diffusion of innovation (DOI) theory by Rogers (1983) (e.g. Marak et al. , 2019 ) or user-centered decision frameworks, such as the unified theory of acceptance and usage of technology (UTAUT) by Venkatesh et al. (2003) (e.g. Schniederjans and Yalcin, 2018 ) or the technology acceptance model (TAM) by Davis (1985) (e.g. Chaudhuri et al. , 2018 ) to examine organizational decision-making. These models contrast not only in terms of the dependent- and independent variables but also in the underlying units of analysis. While some constructs study the action of adoption ( Tsai and Yeh, 2019 ), others merely examine the intention to adopt ( Oettmeier and Hofmann, 2017 ). Besides this characteristic, the dimensions impacting the adoption decision differ to a great extent. While the research study employing user-centered models emphasizes the impact of the individual decision-maker characteristics on the adoption decision ( Steenhuis and Pretorius, 2016 ), firm-centered models highlight the influence of external stakeholders ( Tsai and Yeh, 2019 ). Hence, a holistic overview of adoption criteria and drivers among firms would require analyzing the phenomenon from multiple theoretic angles.

The contributions of this paper are threefold. First, the bibliometric analysis reveals interesting aspects of the existing body of research. The most prominent characteristics of contemporary literature are reflected along descriptive indicators, such as industry, method, model, origin, research outlet or adoption drivers, thus granting relevant insights into academia and practice. Second, the most notable adoption models are carefully analyzed on their inherent attributes and their application fit for the context of organizational 3DP adoption. Findings, for instance, revealed the dominance of DOI across the existing body of research and divulge that this construct is generally applied in combination with user-centered decision frameworks to yield more precise results. Third, an ample range of opportunities for future research are detected and thoroughly explained. Among others, we identified a clear lack of information on the impact environmental variables and contingency factors exerted on the organizational adoption of 3DP. Guidance in relation to the sourcing of industry data, usage of adoption frameworks and avenues for future scientific projects is supplied.

The rest of this review is structured as follows. Section 2 provides an overview of the theoretical background underlying this investigation. The state of the art of 3DP is introduced, and the most commonly applied theoretic models for the adoption of technology are presented. Section 3 discloses the research methodology and explains the data collection and analysis process. Then, the descriptive results are presented and both quantitative findings from the reviewed publications, as well as the results from the latent content analysis, are demonstrated. Section 4 and 5 synthesize the results and discuss future research pathways. Finally, implications and limitations are presented.

2. Theoretical background

2.1 organizational vs consumer 3dp.

3DP has proliferated in the last 15 years among society and has gained vast attention, both, on an individual as well as on an organizational level. 3DP adoption among consumers ( Steenhuis and Pretorius, 2016 ), either as a facilitator to home fabrication ( Anastasiadou and Vettese, 2019 ) or as entrepreneurial starter kit ( Gartner et al. , 2015 ), has found increased awareness among research. Extensive media coverage and decreasing printer costs amplified the diffusion of 3DP on a consumer level. Hence, decision drivers and benefits of 3DP for individual consumers are widely studied ( Fox, 2014 ). The organizational adoption of 3DP, on the other hand, displays a rather untapped area of investigation. 3DPsystems and prices vary drastically depending on their purpose of usage, i.e. desktop or industrial application. Thus, decision-making for the adoption of 3DP on a firm level represents a complex process that involves the allocation of elevated financial and human resources, as well as organizational risks. A much broader range of decision drivers need to be considered for technology adoption on a firm level than on a user level ( Schniederjans, 2017 ). Turbulent market dynamics and firm-internal structures constitute only some of the complexities that need to be contemplated for the organizational adoption of novel technologies ( Tornatzky and Fleischer, 1990 ). Further investigation on this evolving field of research is required to support the managerial decision-making process and as such promotes the diffusion of 3DP among industry.

2.2 Understanding the technology adoption process

Multiple theoretical frameworks have been developed over time to study and understand the phenomenon of technology adoption from an empirical point of view. Depending on the unit upon analysis, these theories either observe adoption from an organizational or an individual perspective. To understand the phenomenon of organizational 3DPT adoption, this paper studies six theories of technology adoption. These frameworks have been selected based on their abundance as well as acceptance among technology adoption research. Among the most commonly discussed models are the theory of planned behavior (TPB) ( Ajzen, 1985 ), the TAM ( Davis, 1985 ), the UTAUT ( Venkatesh et al. , 2003 ), the TEO model ( Tornatzky and Fleischer, 1990 ), the DOI theory ( Rogers, 1983 ) and the institutional theory (IT) ( DiMaggio and Powell, 1983 ; Scott, 1995 ). Table 1 provides an overview of these adoption theories, their aim, drivers, dependent variable, applicability for organizational adoption, applicability among 3DP research as well as references. Dependent variables vary from intention to adopt to adoption behavior, thus emphasizing either actual or potential 3DP adoption.

2.2.1 Theory of planned behavior

The TPB aims to explain and predict human behavior , i.e. action. TPB assumes a behavioral intention prior to the actual behavior and hypothesizes that this intention is influenced by the individual’s attitude toward the behavior , the individual’s subjectively perceived norm of what should be done ( subjective norm ) and the individual’s degree of control over the factors influencing the behavior ( perceived behavioral control ) ( Ajzen, 1985 ). Although TPB was not designed to study technology-related decisions, the theory still sets the basis for major studies on human behavior and as such contributes to extended research on technology adoption among individual members of society. TPB explains the intention to adopt rather than the actual adoption behavior; thus, the time frame between intention and behavior is unknown. Both Schniederjans and Jalcin (2018) as well as Chatzoglou and Michailidou (2019) in their research on the organizational adoption of 3DP have included elements of TPB, such as to understand management’s attitude toward using 3DP. Both scientists studied the managerial intention to adopt 3DP by means of the managers’ attitude toward and perception of the technology. A major limitation of TPB is the lack of account for environmental or economical dimensions of influence on the intention to adopt 3DP. As such, TPB merely represents a tool to predict managerial behavior prior to actual adoption. Research on the organizational adoption of 3DPT has employed TPB only in combination with other adoption models, contemplating additionally for technological, organizational or environmental dimensions (e.g. DOI, TAM and UTAUT).

2.2.2 Technology acceptance model

The TAM aims to predict how users accept and employ technology and draws on behavioral aspects of TPB. TAM hypothesizes that technology usage is influenced by the attitude toward technology usage and consequently the intention to use the technology . The model claims that an individual’s attitude toward technology usage is derived from the user’s perceived ease of use (PEOU) and perceived usefulness (PU) of the technology, and it further acknowledges that external variables influence and moderate the relationship between PU and PEOU ( Davis, 1985 ). The body of research on technology adoption often criticizes the limited predictability of TAM and thus expanded the model to TAM II, including the variables of social influence and cognitive instrumental processes ( Venkatesh and Davis, 2000 ). While the users’ perceived ease of use as well as the perceived usefulness of 3DP represent helpful dimensions in understanding acceptance or rejection of 3DP, they do not explain actual adoption. Commonly labeled as intention-behavior gap, intention is an insufficient prerequisite for a successful action ( Sheeran and Webb, 2016 ). Similar to TPB, TAM I and II represent models that aim to analyze the adoption intention of individual members of society as opposed to organizations. TAM does not take environmental and organizational drivers, such as market dynamics or human resources, into consideration. As such, contemporary research on organizational 3DP adoption has employed TAM mostly in combination with the DOI theory ( Rogers, 1983 ), such as to constitute for the lack of context ( Wang et al. , 2016 ; Oettmeier and Hofmann, 2017 ; Marak et al. , 2019 ). Contemporary research often employs TAM to better comprehend the 3DP adoption intentions among top-management members ( Schniederjans and Yalcin, 2018 ). So far only TAM I has been studied by the underlying body of literature on organizational 3DP adoption.

2.2.3 Unified theory of acceptance and usage of technology

The unified theory of acceptance is based on various aspects of the aforementioned models and aims to explain the behavior of people in their use of technology. UTAUT is acknowledged as one of the most complete frameworks for predicting adoption behavior among individual members of society. UTAUT proposes that usage intention and facilitating conditions directly influence technology usage . Furthermore, the model suggests that the technology usage intention is directly determined by three key constructs ( performance expectancy, effort expectancy and social influence ). Additionally, four moderator variables ( gender, age, experience and voluntariness of use ) impact the relationship between the different exogenous and endogenous variables ( Venkatesh et al. , 2003 ). The increased amount of moderator variables is frequently criticized as artificially improving UTAUTs predictability ( Dwivedi et al. , 2019 ). Similar to TAM, UTAUT is also suffering from the intention-behavior gap, thereby examining intention to use a technology rather than its actual adoption. Alike TPB and TAM, UTAUT may also be applied to study the individual behavior of managers in organizations; however, it does not consider the impact of technology adoption on the organization from a holistic point of view. Despite the inclusion of social influence (e.g. society) and facilitating conditions (e.g. resources) as independent variables defining an individual's intention to adopt, organizational dynamics (e.g. competitors and human resources) and external dimensions (e.g. market and environment) are not contemplated. Hence, to reliably examine the phenomenon of organizational 3DPT adoption, research combined UTAUT with the DOI theory ( Rogers, 1983 ) ( Schniederjans, 2017 ; Marak et al. , 2019 ).

2.2.4 Diffusion of innovation theory

The DOI theory analyzes how, why and at what rate new ideas or technology diffuse among a social system over time ( Rogers, 1983 ). DOI contributes the adoption decision to innovation-specific criteria and suggests that decision-makers undergo a thorough evaluation of the technology´s characteristics, both firm internal as well as external. As such, DOI theorizes that a technology’s relative advantage for the adopting organization, its compatibility with existing technological structures, its perceived complexity , the observability of technology-induced success as well as its anteceding triability all impact the adoption decision ( Rogers, 1983 ). As opposed to TPB, TAM and UTAUT, DOI acknowledges the context upon which technology adoption-decisions are taken and as such constitutes a proper theory for analyzing organizational technology adoption. DOI represents the most frequently applied method for examining the adoption of 3DP in organizations ( Oettmeier and Hofmann, 2017 ; Schniederjans, 2017 ; Chaudhuri et al. , 2018 ; Marak et al. , 2019 ). As DOI aims to understand the DOI among a social system over time, the theory focuses on the bigger picture of adoption rather than emphasizing on multiple distinct firm-internal and external drivers. Scientists employ this method to obtain a broad overview of the determinants of 3DP adoption in firms ( Chatzoglou and Michailidou, 2019 ). While the theory already comprehends a vast range of drivers for organizational technology adoption, still insufficient emphasis is put on the impact of environmental factors ( Hsu et al. , 2006 ), such as stakeholders influence, industry infrastructure or governmental regulation. Especially when examining the adoption of 3DP, environmental dimensions constitute major decision drivers (e.g. governmental funding/subsidies and commercial partner infrastructure). Moreover, research on 3DP adoption frequently combines DOI with individual adoption models (TAM and UTAUT), such as to dive deeper into understanding of individual decision-maker’s motivations ( Wang et al. , 2016 ). All in all, DOI is well-suited for generating an overview on the drivers for 3DP adoption in firms; however, if more profound insights are required, further specific dimensions need to be added to the model (e.g. environmental, organizational and individual) to obtain profound insights.

2.2.5 Technology–organization–environment framework

The TOE framework identifies three crucial aspects that influence technology adoption within an organization. TEO argues that technology- organizational- and environmental-related factors drive adoption. Technological factors describe the perceived characteristics of the technology in terms of its relative advantage for the organization and compatibility with existing structures. Organizational-related motives refer to internal characteristics such as firm size, financial and human resources, internal structure and future vision as well as outlook. Ultimately, environmental factors define all firm-external drivers such as industry dynamics, competitors, trading partners and authorities ( Tornatzky and Fleischer, 1990 ). As opposed to the aforementioned models, TEO examines the technology adoption decision rather than the mere intent of adoption. TEO is frequently employed to examine the adoption of radical technology and also found initial application in the literature on the adoption of 3DP (e.g. Yeh and Chen, 2018a ). The framework is consistent with DOI in terms of its general drivers, however complements the model through its emphasis on the environmental context ( Wang et al. , 2016 ). TEO, on the contrary to DOI, delves deep into the impact of industry stakeholders, governmental entities, market trends or legislation on the organizational adoption decision. Although TEO does not specify decision-maker characteristics to the extent of DOI, TPB, TAM or UTAUT, the management’s experience, vision and support receive attention in the variables constituting the organizational context. The literature on the organizational adoption of 3DP has employed TEO on its own. While no combinations with other adoption models have yet been conducted in this area of research, Tsai and Yeh (2019) and Yeh and Chen (2018) have added the independent variable of 3DP cost to the construct. As TOE has been developed specifically to examine complex technology adoption decisions from an organizational perspective, it emphasizes all processes and variables that impact the adopting entity as part of an industrial ecosystem. As such, extended research on technology adoption manifested that TEO is more appropriate to analyze intrafirm adoption than DOI ( Hsu et al. , 2006 ).

2.2.6 Institutional theory

IT argues that firm-external pressures lead to organizational actions and behavior ( DiMaggio and Powell, 1983 ). The scientific field of innovation and technology management frequently draws back to sociology and as such to IT to observe the phenomenon of isomorphism in decision-making (e.g. Teo et al. , 2003 ). IT hypothesizes that coercive, normative, and mimetic isomorphic pressures exerted by an organization's environment influence firm’s internal decisions. While coercive forces result from trading partner behavior, normative pressure is exerted from industry authorities and mimesis arises from competitor actions ( DiMaggio and Powell, 1983 ; Scott, 1995 ). As such, IT acknowledges that organizational decisions are not only driven by performance goals (e.g. relative advantage) but also by social and cultural factors. To emphasize the influence of stakeholder dynamics on adoption decisions, research on radical technology, frequently applies IT in combination with other adoption models (e.g. Yoon and George, 2013 ; Cao et al. , 2014 ). In order to highlight the impact of institutional pressures exerted on the adopting entity (e.g. from trading partners, competitors and institutions), the literature oftentimes proposes integrating IT in the context of environment as proposed by TEO ( Soares Aguiar and Palma-dos-Reos, 2008 ; Oliveira and Martins, 2011 ). Until to date, only one investigation examined the organizational adoption of 3DP by means of IT ( Schniederjans and Yalcin, 2018 ). Although IT constituted one of many models that have been employed by Schniederjans and Yalcin´s (2018) study, compelling evidence was found for the impact of isomorphic pressures on the adoption of 3DP in organizations. Unfortunately, no quantitative research has yet analyzed the 3DP adoption from an institutional lens. IT embodies a powerful approach to delve into the frequently overlooked impact of institutional forces on technology adoption decisions.

3. Research methodology

What is the current body of research regarding organizational adoption of 3DP in terms of descriptive indicators (methods and models applied, industries investigated, research activity along country and time, research outlet and frequency of drivers)?

Which adoption theory and underlying decision criteria are most frequently applied for explaining organizational adoption of 3DP, and what do we learn from these studies?

Where do we still lack knowledge, and therefore which future research opportunities can be identified in the field of organizational adoption of 3DP.

3.1 Description of analysis process

Once the purpose of the present research was established, the literature selection process was initiated. Screening for inclusion criteria was developed to identify the most appropriate literature for analysis ( Fink, 2014 ). The analysis commenced with an extensive keyword search to source relevant literature studies on the adoption of 3DP technologies. The databases employed were Business Source Complete, Science Direct and Web of Science. The predefined criteria were applied to reduce the search to the most relevant publications in the field of organizational 3DP adoption. Afterward, the articles were quantitatively analyzed on their year of publication, publication outlet, authorship and origin, underlying research methods and applied theoretical frameworks as well as industries upon investigation. This was followed by the content analysis of the underlying drivers for 3DP adoption. The information was coded and synthesized to a higher level of dimensions based on the TOE framework ( Tornatzky and Fleischer, 1990 ).

3.2 Search and selection process

The focus of this paper lies on the understanding of the organizational decision-making process for the adoption of 3DP. Thus, the following keyword string was generated to conduct the search across the three aforementioned databases: (“ 3D printing ” OR “ additive manufacturing ” ) AND (“ adoption ” OR “ decision ” OR “ usage ” OR “ application ” ) . While it was set as a prerequisite for the selected titles to include either the term 3DP or additive manufacturing , the keywords invariably had to include the label adoption OR decision OR usage OR application . The keyword diffusion was not included on purpose, as it represents the macro phenomenon of how many entities of the population have already adopted the technology over time. The search identified a total of 594 fully available articles.

To assure high quality and applicability of the research articles prespecified inclusion criteria were applied to the literature search ( Fink, 2014 ). First, the years of publication were restricted from 2010 to March 2020, as hardly any empiric research on the adoption of 3DP resulted before that year. The number of articles reduced to 483. Second, the search was narrowed down to peer-reviewed articles such as to guarantee scientific rigor of articles (401 articles). Next, we limited the search to English-only publications, thereby reducing the body of literature to 392. Fourth, we reduced the selection to articles originating from management journals only, excluding chemistry, biomedical and in-depth engineering outlets as these hardly draw attention to organizational decision-making processes. In total, 85 articles matched all the criteria and were selected for further content analysis. In the fifth step, we scanned the abstracts of all obtained articles on their fit for the underlying research. Research studies that did not strictly emphasize the organizational process of adopting 3DP and associated decision drivers were excluded. First, we omitted articles discussing the adoption of 3DP among individuals rather than organizations (49). Second, while articles based on quantitative research methods had to apply at least one adoption model, papers based on qualitative analysis had to discuss either drivers, barriers or other factors impacting the organizational adoption decision. As such, and for example, articles analyzing the impact of 3DP on supply chain and inventory or articles examining the adoption, advantages and disadvantages of different 3DP techniques in organizations were removed. In conclusion, 25 publications were identified and selected for this review. We conducted a backward search of all 53 articles to study the referenced literature for any further research ( Levy and Ellis, 2006 ). A total of two further studies were detected, summing up to a final total of 27 papers. In total, two additional research papers that would not have passed the predefined screening criteria have been identified by informal sources and included due to the fact that their results were of interest for the study, making a total of 29 articles. Next, the final selection of papers was evaluated on their quality ( Fink, 2014 ). Qualitative and quantitative research was treated differently. While quantitative research was assessed on the underlying data collection methodology as well as reliability and validity of results, qualitative research was evaluated on the explicitness, comprehensiveness and reproducibility of the employed empirical methodology. No papers were found to lack reliability or empiric evidence. Figure 1 graphically illustrates the selection process and reveals corresponding data.

3.3 Data extraction and analysis

To conduct the bibliometric literature review as well as the underlying content analysis, data needed to be extracted in a systematic manner. Qualitative and quantitative research had to be treated differently ( Rousseau et al. , 2008 ). To further proceed with the analysis, a spreadsheet database was generated. The bibliometric results of the selected articles were thoroughly examined, and the following information was retrieved: article title, authors, location and affiliation, journal, date of publication, keywords, research type, research method, theoretical framework and industry. Microsoft Excel was employed to synthesize and visually represent the recaptured data. Next, data were extracted for the content analysis. In this step, the adoption criteria were obtained from quantitative and qualitative studies. In terms of quantitative research, only those criteria that tested significant on the adoption decision were selected. Qualitative studies were subjected to individual researcher’s judgment; thus, the most frequently cited and evidenced decision criteria were extracted. For the sake of analysis, the selected articles were systematically analyzed, and data were coded according to predefined schemes. The TEO framework was employed to schematize the criteria underlying the organizational adoption of 3DP. Retrieved data were categorized following a deductive category approach and organized in terms of technology-, organization- and environment-specific drivers. The coding process was carried out in MAXQDA v.12. Finally, the results were quantitatively analyzed on their frequencies.

4. Descriptive results

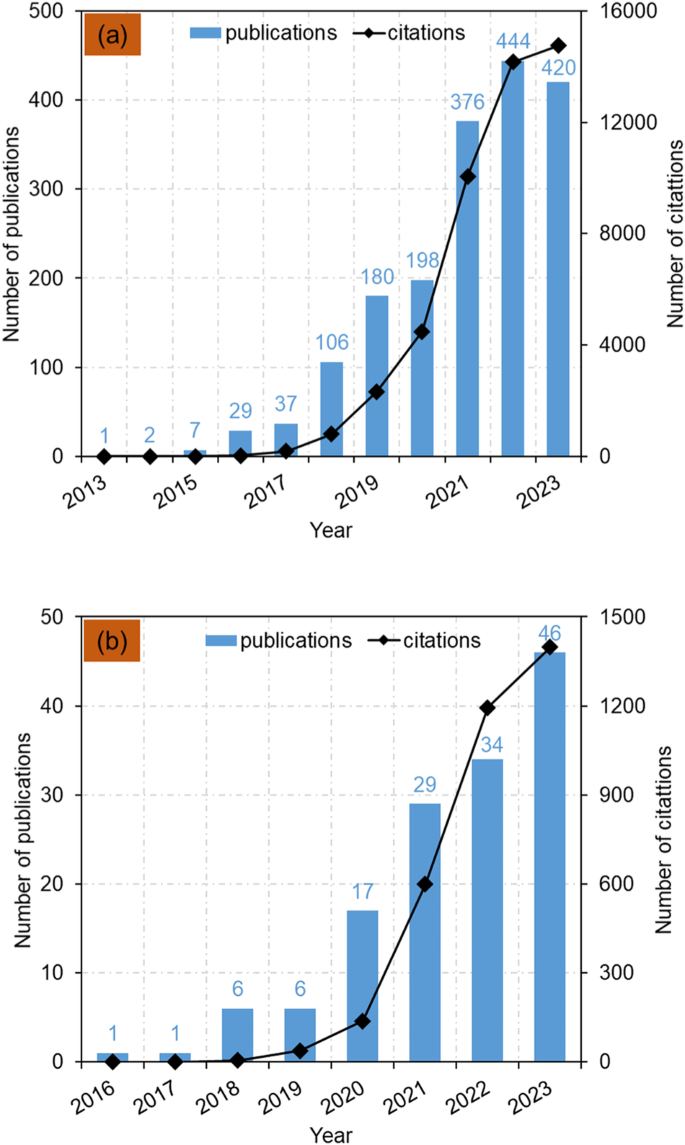

4.1 trend among publications in time.

The literature review confirmed the novelty of the field of 3DP adoption for academia. As shown in Figure 2 , research activity was relatively thin before 2015. The topic first received attention in 2013, however hardly continued in the scientific radar for the next three years. The data observe that the adoption of 3DP from a business and innovation science perspective gained increased interest from 2015 onwards and peaked in 2018. This trend resonates with the overall rate of the technology’s diffusion among industry. Before 2010, 3DP was used mainly by the high-tech sector for rapid prototyping or concept proof. As a result of increased media exposure, the emergence of sophisticated 3DP suppliers as well as decreasing printer costs, the technology has heavily started to enter more mainstream industry after 2010 ( Sculpteo, 2019 ). Thus, empiric data on adoption behavior and trends became available only some years after.

4.2 Publication outlet

Figure 3 illustrates the most frequently employed journals in the field of 3DP adoption. Most articles have been published in Journal of Manufacturing Technology Management (5). An equal number of papers were found in Technology Forecasting and Social Change, International Journal for Production Economics and International Journal for Production Research (3). In total, two publications brought to our awareness by informal sources have been obtained through university databases (doctoral and master thesis). The remaining publications pertained to highly specific journals in the field of innovation management or manufacturing. These findings agree with Bradford’s law observing that a core of journals produces approximately a third of all articles ( Eyers and Potter, 2015 ).

4.3 Authorship and location

In total, 71 authors contributed to the identified literature on 3DP adoption. Approximately 45% of the identified body of research was elaborated by two authors and an additional 21% by three authors. Single-authored articles contributed only to 17% of the grand total, followed by contributions from four and five researchers. Only four out of 29 papers were developed through crosscountry collaborations and mostly constituted interEuropean research alliances. The primary authors country of residence was a selected as main location. The adoption of 3DP was analyzed by academics across various countries; however, it flourished in the USA and Europe.

4.4 Research methods and theoretical framing

The selected articles were furthermore examined on their underlying research methods. Figure 4 illustrates the distribution of publications based on the methodology employed as well as the year published. As visible, the early years of investigation were characterized by explorative research, conducted either through desk research, semistructured interviews or case studies. As a result of the topic's novelty and the consequent lack of empirical evidence, the most commonly employed research method is the in-depth interview with a total number of 12 publications. Once 3DP adoption diffused among industry, the first quantitative data became available and allowed survey-based research methods to consolidate in 2019. Moreover, the first empirical results derived through adoption theories emerged in 2016 along with quantitative studies. Desk research appeared consequently throughout the last ten years, indicating a consistent diffusion of 3DP across organizations.

Figure 5 illustrates the adoption models that have been employed to analyze the organizational adoption of 3DP along the different research methods. The DOI framework was the most employed theory among the underlying body of research, tightly followed by the technology acceptance model. The UTAUT was resulted as the third most-frequently applied model among publications. The TEO model as well as the TPB were both employed by an equal number of publications. Only one paper considered IT for analyzing 3DP adoption. While 76.5% of all quantitative research papers were based on their analysis on specific adoption models, only 47.7% of qualitative papers did so. Half of the publications represent explorative approaches that did not employ adoption theories. In total, eight publications combined indicators and aspects from multiple models. While six papers combined the TAM and the DOI theory, three articles merged DOI and UTAUT. Thus, DOI, UTAUT and TAM represent the most combined concepts among the underlying body of research.

4.5 Industries upon analysis

All reviewed publications based on qualitative and quantitative research methods focused their empirical analyses either on one or multiple industries ( Figure 6 ). Only four articles emphasized their investigation on a single industry, and one-fourth of these articles applied a qualitative research approach. The remaining publications under review, especially all quantitative research papers, revealed data corresponding to multiple industries. This may be the result of the novelty of the topic and still the limited amount of information on specific industries. In total, 15 articles investigated the organizational adoption of 3DP in an industrial manufacturing setting. These publications however did not state any further sub-categorization. The transport industry (automotive and aerospace) was analyzed by one-third of all articles, closely followed by the consumer good industry (textile, jewelry, furniture and sports equipment) and the health and medical sector. Additional settings upon analysis were represented by the electronic, chemical and construction industry. One study can analyze several industries.

4.6 3DP adoption criteria

This section provides a categorization of the criteria influencing the adoption of 3DP and highlights the most interesting learnings associated with these decision drivers. While an ample range of theories have been applied to study 3DP adoption (see Figure 5 ), the underlying research aims to display the most recurrent adoption criteria along the TEO framework, as it represents one of the most appropriate models for analyzing intrafirm technology adoption ( Hsu et al. , 2006 ). As described in section 3.3 , the underlying extraction process differed among qualitative and quantitative studies. Out of the quantitative studies, only those criteria that proved significant in the empirical analysis were identified and counted for the underlying research. In the qualitative studies, those criteria were selected/counted because the authors of the studies found those to be the most influencing ones. As suggested by Weber (1990) criteria were coded as words. Following a deductive approach ( Neuendorf, 2017 ), the criteria were extracted and schematized along three dimensions. The technology context includes all factors that relate to the benefits and barriers, and the technology per se represents for the organization in terms of performance, impact and agility. The organizational context defines all company-internal aspects that impact the adoption decision, both positively as well as negatively. As such, these criteria refer to structural requirements (i.e. size, budget and processes) as well as to organizational readiness (i.e. top management support, technology readiness and experience). Finally, the environmental context describes all firm-external factors that impact the adoption decision. Validity is established through data triangulation, as different sources of data have been reviewed to develop the analysis ( Neuendorf, 2017 ). Table 2 illustrates the critical factors for adoption along three categories and indicates their frequency among the publications selected for this literature review.

4.6.1 Technology context

As observed in Table 2 , technology context represents the most prominent category of adoption drivers with a frequency of 167. Investment costs ( f = 16) represent the most dominant barriers to adoption in terms of frequency. Literature points out high technology acquisition costs, unexpected maintenance costs as well as increased material pricing as important aspects of 3DP adoption (e.g. Yeh and Chen, 2018 ). This is followed by concerns on the technological maturity of 3DP ( f = 13). In this context, the scientific community commonly observes the lack of standardization among printers and output quality (e.g. Weller et al. , 2015 ). In total, six articles emphasized the slowness of the production process that seems rather uncompetitive when compared to traditional manufacturing methods (e.g. Fontana et al. , 2019 ). The review reveals that the technology-specific benefits still outweigh the barriers in terms of frequency among articles. The majority of papers emphasize the possibility to accelerate time to market ( f = 16) through 3DP and elaborates on its positive impact on lead- and ramp-up times as well as manufacturing cycles (e.g. Schniederjans, 2017 ). The opportunity to simplify supply chains ( f = 11), thereby lowering inventory and production steps, as well as skipping tooling and molding functions, represents a further highly quoted driver for 3DP adoption (e.g. Oettmeier and Hofmann, 2017 ). Among the most prominent criteria for 3DP, adoption is the ability to customize products for end users ( f = 9) (e.g, Murmura and Bravi, 2018 ). Cohen (2014) states that 3DP allows the mass customization of up to 200 products a time. The reduction of the environmental impact ( f = 9) through the additive manufacturing technique (zero waste), the possibility to experience absolute design freedom ( f = 9) and create complex products or the option to manufacture small production batches ( f = 4), among others, represent further benefits driving 3DP adoption (e.g. Marak et al. , 2019 ). Interestingly, the limitation in terms of size of printed products and printers per se was only pointed out twice (e.g. Weller et al. , 2015 ). While the organizational context observes the importance of skilled human resources, only one publication mentioned software usage (CAD) as a barrier to 3DP adoption in organizations ( Garza, 2016 ).

4.6.2 Organizational context

Organizational drivers represent the second most important category for adoption among the reviewed literature ( f = 56). The most frequently quoted aspect for 3DP adoption among investigated cases is the organizational readiness ( f = 12). Among others, organizational readiness refers to the firms' willingness to adopt 3DP, its experience with similar technology and the degree of internal rejection (e.g. Candi and Beltagui, 2019 ). The existence of skilled workforce and the concomitant necessity of reskilling existing workforce ( f = 11) exhibit the second most mentioned factor impacting 3DP adoption from an organizational perspective (e.g. Chaudhuri et al. , 2018 ). Furthermore, it seems of utmost importance to evaluate the technologies compatibility ( f = 9) with existing production systems as well as the overall fit with the company’s overall mission and structure (e.g. Tsai and Yeh, 2019 ). The literature also repeatedly acknowledges the support and experience of top management teams ( f = 7) as well as the importance of a dynamic organizational culture ( f = 5 ) for3DP adoption (e.g. Mellor et al. , 2014 ). Some articles further emphasized the importance of the alignment among firm-internal departments ( f = 4), such as manufacturing and IT for 3DP adoption. An increased company size was found to be both, a promoter as well as an inhibitor of organizational 3DP adoption (e.g. Kianian et al. , 2016 ). Steenhuis et al. (2020) manifested the impact of company age and location on the adoption behavior.

4.6.3 Environmental criteria

Although, highly significant, environmental decision criteria appear less frequently among the 3DP literature and only represent a total of 31 quotes in this research. This results from the limited application of adoption models emphasizing firm-external decision drivers such as TEO or IT, among the underlying body of literature. Oettmeier and Hoffman (2017) emphasize the impact of coercive forces ( f = 5) exerted by trading partners, competitors ( f = 3) as well as the overall effect of social influence ( f = 5) on the adoption decision. Existing research repeatedly acknowledges market and technology turbulence ( f = 4 ) as well as the overall competitiveness of the industrial environment as adoption triggers (e.g. Candi and Beltagui, 2019 ). Various papers referred to facilitating conditions ( f = 5) (governmental or regulatory support and training initiatives) as incentive for 3DP adoption (e.g. Oettmeier and Hofmann, 2017 ). The readiness of the 3DP supplier landscape, in terms of number of technology and material vendors ( f = 4), also appears to play an important role for organizational technology adoption ( Tsai and Yeh, 2019 ). Furthermore, compliance with evolving market trends and expectations ( f = 2) was found as a driver to adoption ( Yeh and Chen, 2018a ).

5. Discussion of results

Although the organizational adoption of 3DP has gained increased scientific interest from 2015 onwards, our findings show that this field is still in its infancy. This understanding resonates with the overall diffusion of 3DP technology among industry ( Wohlers Associates, 2019 ). Until to date, research has been dominated by qualitative methods, such as to generate a common understanding of the topic and yield first explorative results on the factors driving 3DP adoption in organizations. Quantitative research activity was commenced in 2016, along with the availability of industry data, and since then it is employed in multiple adoption models to study the phenomenon in an empiric manner.

5.1 Theoretic constructs

While the most commonly applied adoption theory across the underlying body of research was the DOI, almost all studies combined this model with at least with one additional construct (TPB, UTAUT or TAM. TPB, UTAUT and TAM are user-centered decision models that emphasize the perception and characteristics of an individual toward an action, i.e. technology adoption. We discovered that, besides analyzing the impact of the technology per se (e.g. relative advantage) through DOI, this specific combination stresses the influence of top management on the adoption decision. The dimensions driving technology adoption among firms however differ vastly from user-centered adoption processes. Thus, they require a more holistic approach to analyze not only the technology and the individual decision-maker but also the organizational and environmental characteristics a firm is immersed into. The preceeding theoretic constructs, however, hardly study the adoption decision from an institutional angle. The TOE model and the IT on the other hand contribute organizational decision-making to environmental factors of influence. Even though the body of literature on the organizational adoption of radical technologies frequently emphasizes the impact of firm-external conditions on the adoption decision ( Wang et al. , 2010 ; Cao et al. , 2014 ), this topic has hardly experienced any discussion in the field of 3DP.

5.2 Data characteristics and origin

Our analysis suggests that as opposed to DOI, TPB, UTAUT and TAM, TEO and IT require industry-specific data to yield most adequate results. Industry homogeneity across the sample is a prerequisite to obtain conclusive and generalizable results on the impact of industry dynamics on technology decision-making. Due to the novelty of the field, industry data are still premature. Most quantitative studies have acquired their data from organizations pertaining to multiple industries. Only four out of 29 papers have employed a single-industry approach. Such heterogeneous results neither allow to identify differences in organizational behavior across industries nor to propose industry-specific adoption plans. The limited rate of diffusion across industries ( Steenhuis et al. , 2020 ) and the associated lack of information represent a major impediment for investigating the phenomenon from an holistic angle. We conclude that corporate adoption decisions ultimately have to be examined from an environmental, organizational, and technological point of view. We propose TEO as the most complete option for analyzing the phenomenon of 3DP adoption in organizations. Besides the integration of industry specific variables, TEO also represents the only model that analyzes the action of adopting a technology rather than the intent to adopt. This again is a reflection of existent industry data and sample characteristics. While research based on DOI, TPB, UTAUT and TAM included 3DP adopters and nonadopters in their sampling process, TEO emphasizes only those cases that have already taken a decision. Studying adoption, as opposed to hypothetical adoption, allows to draw conclusions on the actual impact of firm-internal and external drivers on the adoption decision.

5.3 Adoption drivers

Content analysis furthermore revealed that the technological dimensions, as compared to the organizational or environmental dimensions, of influence have received most attention among the scientific community. More than half of all researched articles recognized the significance of technology-related adoption drivers, such as the ability of 3DP in accelerating time to market, its ease of use and the associated simplification of supply chains. Furthermore, a third of all articles acknowledged the firm’s overall innovativeness, the existence of skilled work and characteristics of top-management as critical decision drivers. Contrarily, hardly any discussion occurred on the influence of organizational contingency factors (e.g. firm size and firm age) on adoption. Additionally, overall information on the impact of market trends, facilitating conditions, institutional pressures or supplier landscape is limited. While some articles discuss the effect of external pressures on the adopting entity ( Oettmeier and Hofmann, 2017 ; Schniederjans, 2017 ; Tsai and Yeh, 2019 ), no differentiation is made among its source of emission. According to IT, pressure is exerted from competitors, trading partners and authorities. The impact of isomorphism on the adoption of radical manufacturing technology is well known in the contemporary literature (e.g. Kuan and Chau, 2001 ; Alshamaila et al. , 2013 ), however understudied in the field of 3DP.

We conclude that the lack of industry data is limiting both, the extent of quantitative research methods across the field of organizational 3DP adoption as well as the application of integral theoretical constructs. This results in a polarized set of findings, with vast knowledge being generated on the benefits and barriers of the technology for the organization, but relatively little information on the impact of a firm’s environment or contingency factors exert on the adoption decision was obtained. Findings of interest for the managerial audience are yet limited, as hardly any in-depth information on specific industries was generated so far, neither through survey nor case studies. Moreover, most existent results emphasized the intent of adoption rather than the experience of already adopters.

6. Opportunities for future research

The underlying work detected various untapped areas of research; opportunities for future investigation are highlighted in the following paragraphs.

6.1 Maturity of industry data

In-depth analysis of the organizational adoption of 3DP and underlying drivers requires more and specialized industry data, both from (1) specific industries as well as from (2) 3DP adopters. First, future research should emphasize on the action of adoption rather than the intent, and thus investigate adoption behavior among organizations that have already integrated 3DP into their manufacturing processes. This would not only support in validating past hypothesis but also induce more generalizable results on 3DP adoption. Second, as adoption behavior varies across industries, data from single industries, either quantitatively or qualitatively (industry case study) derived, would allow to analyze the impact of the industrial environment on the adoption decision. Results from single industries would constitute a useful tool for comparing 3DP diffusion and adoption characteristics across industries and moreover facilitate decision-making for future adopters.

6.2 Characteristics of adopters vs nonadopters

We recommend future studies to compare the characteristics of adopting and nonadopting organizations from an empirical perspective. The frequency analysis revealed that organizational readiness represents one of the most crucial drivers for adoption. A comparison among adopters and nonadopters would yield valuable insights into how to prepare firms for technology adoption. Also the experience of top management with the technology seems of utmost importance for successful organizational adoption. Here future research could investigate the impact of top management experience on 3DP usage by means of user-centered models (UTAUT and TAM).

6.3 Emphasis on the environmental context

The underlying research has placed little emphasis on the impact of firm-external factors on the organizational adoption decision. The environmental context represents only 12% of overall quotes in our content analysis. Hardly any research studied the impact that stakeholders have on organizational adoption behavior. Governmental and regulatory support, i.e. subsidies or educational initiatives or restrictions, i.e. environmental legislation, IP rights, received even less attention among literature studies. As such, profound analyses of the impact of institutional drivers (industry stakeholders: competitors, trading partners and government) on the adoption decision through IT would represent a fruitful area of research. Future studies might also conduct semistructured interviews with regulatory institutions to understand how contemporary regulation and legislation promotes or inhibits the diffusion of 3DP among industries.

6.4 Impact of contingency factors

While the impact of organizational characteristics, such as technology readiness and existence of skilled workforce, was frequently validated among existing research, contingency criteria were hardly investigated. Firm origin, size and age may be of utmost importance for technology adoption. Future research could aim to answer the question of whether firm age impacts the technology adoption decision, thus whether incumbent firms are more likely to adopt 3DP technology than new entrants. Furthermore, a macro study may be conducted to holistically analyze the phenomenon, applying TEO and integrating contingency factors as independent rather than moderator variables.

6.5 Metaanalysis on adoption drivers

While the content analysis revealed that the relative advantage offered by 3DP represents a significant adoption driver across almost all quantitative studies, other drivers appear to depend on the organizational and environmental context the firm is immersed into. Until today, no metaanalysis has yet been conducted to study the relevance of single adoption criteria across the quantitative studies on the organizational adoption of 3DP. Future research by means of metaanalysis could support the existing body of research in generalizing and validating existent findings.

7. Implications and limitations

This study thoroughly reviewed the existing body of research on the adoption of 3DP and generated valuable insights into both academia as well as management. Our findings support this growing scientific community in encountering untapped areas of research and channeling upcoming scientific projects. The bibliometric analysis of literature conveys an overview of the existing body of research, patterns and opportunities. Additionally, the critical analysis of contemporary adoption models, as well as their inherent characteristics, allows to better understand the interplay between results and theory, thus supporting future research in selecting the most appropriate adoption model. As such, the underlying review represents a valuable base of information, theory and sources for any empirical work on 3DP. Our results also offer relevant insights for practice, especially managerial decision-makers on the verge of technology adoption. The adoption drivers revealed in our study represent appropriate factors of consideration for manufacturing managers during the decision-making process. Furthermore, our results generate awareness on the effect 3DP adoption exerts on the different areas of an organization, thus supporting management in appraising the impact of technology integration in a holistic manner. Hence, the underlying work can serve as a guide for decision-making and as support in evaluating all possible implications of 3DP adoption in organizational environment.

Even though an ample range of literature was examined to develop the underlying review, and the screening criteria employed were developed in an inclusive way, there may still exist literature of interest that has not been included. Furthermore, it is paramount to acknowledge that due the nature of content analysis, the prominence of the adoption criteria is measured in terms of frequencies as opposed to their effective impact on the phenomenon under analysis. Thus, content analysis cannot serve to generalize the impact of particular drivers on the adoption of 3DP. To measure the impact, the obtained results would require to be quantitatively tested.

Publication selection strategy and final selection

Distribution of publications from 2010 to 2020

Distribution of publications across journals

Number of publications per year and per research method

Theoretical perspectives used in publications

Industries upon analysis (multiple industries per publication)

Adoption theories

3DP adoption drivers in organizations

Note(s) : * Relevant authors but not exclusive

Ajzen , I. ( 1985 ), From Intentions to Actions: A Theory of Planned Behavior. Action and ControlFrom Cognition to Behavior , Springer-Verlag , New York .

Alshamaila , Y. , Papagiannidis , S. and Li , F. ( 2013 ), “ Cloud computing adoption by SMEs in the north east of England: a multi-perspective framework ”, Journal of Enterprise Information Management , Vol. 26 , pp. 250 - 275 , doi: 10.1108/17410391311325225 .

Anastasiadou , C. and Vettese , S. ( 2019 ), “ From souvenirs to 3D printed souvenirs. Exploring the capabilities of additive manufacturing technologies in (re)-framing tourist souvenirs ”, Tourism Management , Vol. 71 , pp. 428 - 442 .

Attaran , M. ( 2017 ), “ The rise of 3-D printing: the advantages of additive manufacturing over traditional manufacturing ”, Business Horizons , Kelley School of Business, Indiana University , Vol. 60 No. 5 , pp. 677 - 688 , doi: 10.1016/j.bushor.2017.05.011 .

Candi , M. and Beltagui , A. ( 2019 ), “ Effective use of 3D printing in the innovation process ”, Technovation , Vols 80–81 , November 2017 , pp. 63 - 73 , doi: 10.1016/j.technovation.2018.05.002 .

Cao , D. , Li , H. and Wang , G. ( 2014 ), “ Impacts of isomorphic pressures on BIM adoption in construction projects ”, Journal of Construction Engineering and Management , Vol. 140 No. 12 , pp. 1 - 9 , doi: 10.1061/(ASCE)CO.1943-7862.0000903 .

Chatzoglou , P. and Michailidou , V. ( 2019 ), “ A survey on the 3D printing technology readiness to use ”, International Journal of Production Research , Vol. 57 No. 8 , pp. 2585 - 2599 , doi: 10.1080/00207543.2019.1572934 .

Chaudhuri , A. , Rogers , H. , Soberg , P. and Pawar , K. ( 2018 ), “ The role of service providers in 3D printing adoption ”, Industrial Management and Data Systems , Vol. 119 No. 6 , pp. 1189 - 1205 , doi: 10.1108/IMDS-08-2018-0339 .

Cohen , D. ( 2014 ), “ Fostering mainstream adoption of industrial 3D printing: understanding the benefits and promoting organizational readiness ”, 3D Printing and Additive Manufacturing , Vol. 1 No. 2 , pp. 62 - 69 , doi: 10.1089/3dp.2014.0007 .

Davis , F. ( 1985 ), A Technology Acceptance Model for Empirically Testing New End-User Information Systems : Theory and Results , Massachusetts Institute of Technology , available at: http://hdl.handle.net/1721.1/15192 .

DiMaggio , P. and Powell , W. ( 1983 ), “ The iron cage revisited: institutional isomorphism and collective rationality in organizational fields ”, American Sociological Review , Vol. 48 , pp. 147 - 160 , available at: http://10.0.9.3/2095101 .

Dwivedi , Y. , Rana , N. , Jeyaraj , A. , Clement , M. and Williams , M. ( 2019 ), “ Re-examining the unified theory of acceptance and use of technology (UTAUT): towards a revised theoretical model ”, Information Systems Frontiers , Information Systems Frontiers , Vol. 21 No. 3 , pp. 719 - 734 , doi: 10.1007/s10796-017-9774-y .

Eyers , D.R. and Potter , A.T. ( 2015 ), “ E-commerce channels for additive manufacturing: an exploratory study ”, Journal of Manufacturing Technology Management , Vol. 26 No. 3 , pp. 390 - 411 , doi: 10.1108/JMTM-08-2013-0102 .

Fink , A. ( 2014 ), Conducting Research Literature Reviews: From the Internet to Paper , [2014] , 4th ed. , SAGE , Thousand Oaks, CA , available at: https://search.library.wisc.edu/catalog/9910206565302121 .

Fontana , F. , Klahn , C. and Meboldt , M. ( 2019 ), “ Value-driven clustering of industrial additive manufacturing applications ”, Journal of Manufacturing Technology Management , Vol. 30 No. 2 , pp. 366 - 390 , doi: 10.1108/JMTM-06-2018-0167 .

Fox , S. ( 2014 ), “ Third wave do-it-yourself (DIY): potential for presumption, innovation, and entrepreneurship by local populations in regions without industrial manufacturing infrastructure ”, Technology in Society , Vol. 39 , pp. 18 - 30 .

Gartner ( 2019 ), “ Hype cycle ”, available at: https://www.gartner.com/en/documents/3947508/hype-cycle-for-3d-printing-2019 .

Gartner , J. , Maresch , D. and Fink , M. ( 2015 ), “ The potential of additive manufacturing for technology entrepreneurship: an integrative technology assessment ”, Creativity and Innovation Management , Vol. 24 No. 4 , pp. 585 - 600 .

Garza , J. ( 2016 ), Understanding the Adoption of Additive Manufacturing , Massachusetts Institute of Technology, available at: http://hdl.handle.net/1721.1/110892 .

Gupta , B.M. and Dhawan , S.M. ( 2018 ), “ Three dimensional (3D) printing: a scientometric assessment of global publications output during 2007-16 ”, DESIDOC Journal of Library and Information Technology , Vol. 38 No. 4 , pp. 238 - 245 , doi: 10.14429/djlit.38.4.12300 .

Hsu , P.-F. , Kraemer , K.L. and Dunkle , D. ( 2006 ), “ Determinants of E-business use in U.S. Firms ”, Routledge , International Journal of Electronic Commerce , Vol. 10 No. 4 , pp. 9 - 45 , doi: 10.2753/JEC1086-4415100401 .

Jirsák , P. and Brunet-Thornton , R. ( 2019 ), “ Perspectives of operational additive manufacturing case studies from the Czech aerospace industry ”, Journal of Eastern European and Central Asian Research , Vol. 6 No. 1 , pp. 179 - 180 , doi: 10.15549/jeecar.v6i1.273 .

Kianian , B. , Tavassoli , S. , Larsson , T. and Diegel , O. ( 2016 ), “ The adoption of additive manufacturing technology in Sweden ”, Elsevier B.V. , Procedia CIRP , Vol. 40 , pp. 7 - 12 , doi: 10.1016/j.procir.2016.01.036 .

Kuan , K. and Chau , P. ( 2001 ), “ A perception-based model for EDI adoption in small businesses using a technology-organization-environment framework ”, Information and Management , Vol. 38 No. 8 , pp. 507 - 521 , doi: 10.1016/S0378-7206(01)00073-8 .

Levy , Y. and Ellis , T. ( 2006 ), “ A systems approach to conduct an effective literature review in support of information systems research ”, Informing Science , Vol. 9 , pp. 181 - 211 , doi: 10.28945/479 .

Long , Y. , Pan , J. , Zhang , Q. and Hao , Y. ( 2017 ), “ 3D printing technology and its impact on Chinese manufacturing ”, International Journal of Production Research , Vol. 55 No. 5 , pp. 1488 - 1497 , doi: 10.1080/00207543.2017.1280196 .

Marak , Z. , Tiwari , A. and Tiwari , S. ( 2019 ), “ Adoption of 3D printing technology: an innovation diffusion theory perspective ”, International Journal of Innovation , Vol. 7 No. 1 , pp. 87 - 103 , doi: 10.5585/iji.v7i1.393 .

Martinsuo , M. and Luomaranta , T. ( 2018 ), “ Adopting additive manufacturing in SMEs: exploring the challenges and solutions ”, Journal of Manufacturing Technology Management , Vol. 29 No. 6 , pp. 937 - 957 , doi: 10.1108/JMTM-02-2018-0030 .

Mayring , P. ( 2000 ), Qualitative Inhaltsanalyse. Grundlagen und Techniken , Deutscher Studien Verlag , Weinheim .

Mellor , S. , Hao , L. and Zhang , D. ( 2014 ), “ Additive manufacturing: a framework for implementation ”, International Journal of Production Economics , Vol. 149 , pp. 194 - 201 , doi: 10.1016/j.ijpe.2013.07.008 .

Murmura , F. and Bravi , L. ( 2018 ), “ Additive manufacturing in the wood-furniture sector: sustainability of the technology, benefits and limitations of adoption ”, Journal of Manufacturing Technology Management , Vol. 29 No. 2 , pp. 350 - 371 , doi: 10.1108/JMTM-08-2017-0175 .

Neuendorf , K. ( 2017 ), The Content Analysis Guidebook , 2nd ed. , SAGE Publications , Los Angeles .

Niaki , M. and Nonino , F. ( 2017 ), “ Impact of additive manufacturing on business competitiveness: a multiple case study ”, Journal of Manufacturing Technology Management , Vol. 28 No. 1 , pp. 56 - 74 , doi: 10.1108/JMTM-01-2016-0001 .

Oettmeier , K. and Hofmann , E. ( 2017 ), “ Additive manufacturing technology adoption: an empirical analysis of general and supply chain-related determinants ”, Springer , Berlin Heidelberg , Journal of Business Economics , Vol. 87 No. 1 , pp. 97 - 124 , doi: 10.1007/s11573-016-0806-8 .

Oliveira , T. and Martins , M. ( 2011 ), “ Literature review of information technology adoption models at firm level ”, The Electronic Journal Information Systems Evaluation , Vol. 14 No. 1 , pp. 110 - 121 .

Rogers , E.M. ( 1983 ), Diffusion of Innovation , 3rd ed. , Free Press , New York .

Rousseau , D. , Manning , J. and Denyer , D. ( 2008 ), “ Evidence in management and organizational science: assembling the field's full weight of scientific knowledge through syntheses ”, The Academy of Management Annals , Vol. 2 No. 1 , pp. 475 - 515 , doi: 10.1080/19416520802211651 .

Rylands , B. , Böhme , T. , Gorkin , R. , Fan , J. and Birtchnell , T. ( 2016 ), “ The adoption process and impact of additive manufacturing on manufacturing systems ”, Journal of Manufacturing Technology Management , Vol. 27 No. 7 , pp. 969 - 989 , doi: 10.1108/JMTM-12-2015-0117 .

Sandström , C. ( 2015 ), “ Adopting 3D Printing for manufacturing – the case of the hearing aid industry ”, Adopting 3D Printing for Manufacturing – The Case of the Hearing Aid Industry , No. 262 , pp. 1 - 20 .

Sandström , C. ( 2016 ), “ The non-disruptive emergence of an ecosystem for 3D Printing - insights from the hearing aid industry's transition 1989-2008 ”, Elsevier , Technological Forecasting and Social Change , Vol. 102 , pp. 160 - 168 , doi: 10.1016/j.techfore.2015.09.006 .

Schniederjans , D. ( 2017 ), “ Adoption of 3D-printing technologies in manufacturing: a survey analysis ”, Elsevier , International Journal of Production Economics , Vol. 183 No. November 2016 , pp. 287 - 298 , doi: 10.1016/j.ijpe.2016.11.008 .

Schniederjans , D. and Yalcin , M. ( 2018 ), “ Perception of 3D-printing: analysis of manufacturing use and adoption ”, Rapid Prototyping Journal , Vol. 24 No. 3 , pp. 510 - 520 , doi: 10.1108/RPJ-04-2017-0056 .

Scott , R. ( 1995 ), Institutions and Organizations , S. Publications , Thousan Oaks , doi: 10.3917/mana.172.0136 .

Sculpteo ( 2019 ), “ The state of 3D printing ”, available at: https://info.sculpteo.com/the-state-of-3d-printing-report ( accessed: 5 January 2020 ).

Sheeran , P. and Webb , T. ( 2016 ), “ The intention–behavior gap ”, Social and Personality Psychology Compass , Vol. 10 No. 9 , pp. 503 - 518 , doi: 10.1111/spc3.12265 .

Snyder , H. ( 2019 ), “ Literature review as a research methodology: an overview and guidelines ”, Journal of Business Research , Vol. 104 , March , pp. 333 - 339 , doi: 10.1016/j.jbusres.2019.07.039 .