- History & Overview

- Meet Our Team

- Program FAQs

- Social Studies

- Language Arts

- Distance Learning

- Population Pyramids

- World Population “dot” Video

- Student Video Contest

- Lower Elementary (K-2)

- Upper Elementary (3-5)

- Middle School (6-8)

- High School (9-12)

- Browse all Resources

- Content Focus by Grade

- Standards Matches by State

- Infographics

- Articles, Factsheets & Book Lists

- Population Background Info

- Upcoming Online Workshops

- On-Demand Webinar Library

- Online Graduate Course

- Request an Online or In-person Workshop

- About Teachers Workshops

- About Online Teacher Workshops

- Pre-Service Workshops for University Classes

- In-Service Workshops for Teachers

- Workshops for Nonformal Educators

- Where We’ve Worked

- About the Network

- Trainer Spotlight

- Trainers Network FAQ

- Becoming a Trainer

- Annual Leadership Institutes

- Application

6 Ways to Reduce Factory Pollution

By Julia Davis | August 2, 2022

Industrial waste from factories is inevitable. And the ways factories manage that waste affect the surrounding environment, as well as human health. If not properly disposed of, industrial waste can contaminate soil, air, and water.

But there are points throughout a factory’s lifespan, and its entire production process, where changes can be made to reduce the pollution they produce and ensure proper precautions are in place to protect the environment around them.

1. Building Factories in the Right Place

The best way to reduce pollution in important ecosystems is to keep them from harm’s way in the first place. When new industrial sites are being built, it is important to factor in location and the potential impact the site would have on the surrounding environment. Characteristics such as climate and topography significantly affect how pollutants spread, and these factors also need to be considered. As we continue to build factories and industrial sites, making smart decisions about their locations can help reduce the impacts of the inevitable waste that comes from the factory.

2. Powering Factories with Renewable Energy

Energy consumption is one of the main contributors to factory air pollution. Therefore, factories that require less energy to operate produce less air pollution. A large-scale shift to using renewable energy sources to power factories would result in less pollution over time and could also save factories money in the long run. But the initial investment in greener energy sources is often a hurdle that prevents many factories from making the switch to renewables, even if it makes financial and environmental sense when looking at the bigger picture.

3. Analyzing Factory Waste

Pollution is tied to waste that is created during the production process. But before factories can effectively work on decreasing waste, they need an accurate picture of the waste at hand. By analyzing their waste output, factories can determine the amounts of different types of waste like food waste, chemical waste, glass, paper, and other elements. Once they have a clear picture of where they are making waste, it’s much easier to make processes more efficient by upgrading equipment, reorganizing inventory, and establishing recycling systems for reusing materials at various stages of production.

4. Proper Treatment of Factory Waste

The proper treatment of waste at the end of the production process is key to reducing factory pollution. Waste treatment is defined as the practice of changing the properties of industrial hazardous waste and making it less harmful. These changes can be physical, chemical, or biological. Physical treatments are processes that may change the shape or size of the waste. In contrast, chemical treatments use chemicals to alter the composition of the waste, and biological treatments use organisms to break down waste components into simpler organic matter and biomass. Treating waste in these ways before it leaves the facility allows factories to reduce the volume and toxicity of their waste before disposal.

5. Factories Must Run Environmental Impact Assessments

Companies should perform regular environmental impact assessments within their factories to identify potential harmful impacts their waste may have on the natural ecosystem. If harmful impacts are discovered in this assessment, it is the company’s responsibility to take the necessary actions required to address the problem, and correct any negative consequences that have developed.

6. Laws and Enforcement Can Help Prevent Factory Waste

In addition to implementing these regulations, it is equally important for governmental agencies to take firm action against industries that do not follow pollution protocols and offer significant rewards for companies that operate within guidelines.

Image credits: Factory ( The Ruwais Refinery by Rickmaj is licensed under CC BY-SA 4.0 ); Windmills and solar panels ( Renewable Energy on the Grid by Kenueone is licensed under CC0 1.0 ); Recycling facility ( African Waste Management Experts Visit Rwanda E-Waste Recycling Facility – Rwanda Green Fund Investment by Rwanda Green Fund is licensed under CC BY-ND 2.0 ); Man treating waste ( African Waste Management Experts Visit Rwanda E-Waste Recycling Facility – Rwanda Green Fund Investment by Rwanda Green Fund is licensed under CC BY-ND 2.0 ); Men in facility ( Acting Secretary Wolf Tours Marine Terminal Facility (8) by the U.S. Department of Homeland Security); Gavel and books ( Court Gavel – Judge’s Gavel – Courtroom by wp paarz is licensed under CC BY-SA 2.0 )

Related Resources

Energizing policies.

Students research an energy-related topic in the United States or Canada and consider possible alternatives, weighing costs and benefits... Read More »

Electronic Waste: The Case of Agbogbloshie, Ghana

Solid waste case study reading: A profile of a town in Ghana that is the world's capital of e-waste. Read More »

About Population Education

Population Education provides K-12 teachers with innovative, hands-on lesson plans and professional development to teach about human population growth and its effects on the environment and human well-being. PopEd is a program of Population Connection. Learn More About PopEd .

Privacy Overview

Online Trade Magazine - Industry 4.0 Advanced Manufacturing and Factory Automation

With the constant growth in demand for manufactured goods and environmental protections under coordinated assault, there’s never been a more important time for manufacturers to take their part in air pollution seriously.

How to Prevent Industrial Air Pollution in Manufacturing

Scott Huntington | Off The Throttle

With the constant growth in demand for manufactured goods and environmental protections under coordinated assault, there’s never been a more important time for manufacturers to take their part in air pollution seriously.

Industrial manufacturing, along with the construction industry, were the two largest polluters in 2018, both contributing to the second-largest year-over-year increase in air contaminants in two decades.

Some of the most common airborne pollutants generated by manufacturing and other industrial sectors include volatile organic compounds (VOCs), hazardous air pollutants (HAPs) and solid particulate matter (PM). Experts link these and hundreds of other contaminants to severe health problems in humans and wildlife, environmental degradation and contaminated air and water supplies.

Manufacturers must keep our air clean and healthy. The following provides a look at some of the most effective ways to minimize and prevent industrial air pollution emanating from factories.

1. Make the Switch to Clean Energy Sources

Facilities that use coal or natural gas to generate electricity contribute to water and air pollution all over the world. Scientists also link these resources to breathing problems, heart attacks, neurological damage, cancers and other grave and chronic health problems. Paper and concrete manufacturing plants are some of the heaviest users of fossil fuels in manufacturing, but they are far from alone.

Whereas pollutants from coal are responsible for a $74.6billion annual impact on public health in the U.S., clean energy generated from solar and wind contribute no air pollution whatsoever. Biomass and geothermal systems are an acceptable middle-ground — they create some air pollutants, but in vastly lower levels than natural gas — and especially coal-fired plants.

Natural gas is, however, another imperfect but net-positive choice for manufacturers looking for an alternative to more destructive fossil fuels. Natural gas outputs negligible sulfur- and mercury-based pollution.

Additionally, according to the Union of Concerned Scientists, for every 10,000 homes — or the equivalent manufacturing facilities — powered with natural gas, global society stands to eliminate 1,900 tons of nitrogen oxide, 3,900 tons of nitrogen oxide and 5,200 tons of particulates per year that would otherwise enter the air and surrounding environment.

2. Use Technology to Destroy Pollutants at the Source

For cases where it’s not feasible to switch to clean energy immediately, some manufacturers turn to a variety of technologies to destroy air pollution at the source before it enters the earth’s atmosphere. These abatement technologies nullify the most destructive air pollutants, like those mentioned above, and reduce the ecological footprint of manufacturing sites.

Several mechanisms are available that provide this functionality, but not all of them are effective for every pollutant. Some of the relevant technologies include:

Catalytic oxidizers : These machines use intense temperatures and chemical catalysts to render air pollutants down into their constituent compounds, which may then be harmlessly released.

Regenerative thermal oxidizers (RTOs) : With RTOs, factories repurpose industrial waste heat to destroy pollutants within networks of heat exchangers.

Rotary concentrators : Like the name suggests, rotary concentrators rotate at high speed to separate air pollution into a hydrophobic media, where an oxidizer destroys it.

Carbon dioxide is perhaps the best-known air pollutant and contributor to climate change, but there are others — including cadmium, mercury, sulfur dioxide and hydrogen sulfide.

Wet scrubbers are another air pollution mitigation technology to consider, and they deliver the benefit of tackling both gaseous waste, like these, as well as particulate matter before it can enter the atmosphere or the surrounding environment.

3. Choose Non-Toxic Materials to Manufacture Goods

Far too many companies rely on supply chains riddled with raw materials that have the potential to become toxic once released into the air and water. Milling and grinding processes, like those that drive paint and coating operations, release ground-level ozone , VOCs, particulates and heavy metals into the atmosphere, where they impact the health of humans and wildlife.

The Environmental Protection Agency recommends that manufacturers identify raw materials and additives containing chromium, mercury and lead, and replace them with non-hazardous biocide alternatives. Doing so maintains these products’ desirable bacteria-eliminating properties without the risk to health and air quality posed by heavy metals.

Styrene is another material to watch for and eliminate from the supply chain. Atomized styrene can enter the air while fiberglass and plastics are being manufactured or sprayed in place. Instead of risking kidney disease, chronic fatigue and other health problems, manufacturers can substitute low-styrene gels and resins or use materials that rely on ultraviolet curing instead of traditional methods.

Naturally, there will be times when there aren’t any convenient material substitutions to be made. Silica dust, which comes from quartz, is a common and extremely harmful particulate pollutant generated by the manufacture and installation of masonry products, soils, concrete and other construction products.

Training workers to handle essential materials like these , and providing them with adequate protective equipment and exposure plans is essential under OSHA standards as well as common sense.

4. Deploy More Effective Enterprise Planning Techniques

Imbalances between supply and demand have a more direct impact on air pollution than you might expect. When factories are powered up and cranking out products for which there’s little demand, they are contributing to air pollution unnecessarily.

The act of manufacturing products that aren’t needed contributes to air pollution from one end of the product’s life cycle to the other. In the United States, solid waste in landfills is the third-largest contributor to methane emissions. Municipal waste also increases levels of VOCs and other pollutants in the air.

What this means is that manufacturers across the world must find ways to more finely tune the balance between supply and demand and keep unneeded factory activities to a minimum and unwanted products out of the supply chain and distribution networks.

Deloitte points to predictive analytics and machine learning as a way to find this balance. These technologies keep manufacturers, distributors, retailers and customers on the same page with respect to demand for products. They also predict and optimize the best approach to manufacturing activities, production schedules and a host of other supply chain activities so that only essential operations are underway at any given time.

Clean Air Is Good for the Environment and Good for Business

It’s extremely difficult to ignore the importance of eliminating industrial waste, including air pollution. The World Economic Forum says it plainly enough — clean air is good for business. The previously mentioned impact on healthcare costs translates into missed shifts and poor productivity. The world could lose 3.8 billion workdays per year by 2060 if trends continue.

Given all of this, there’s plenty of reason for manufacturers to take air pollution more seriously. Now we know a few ways to do so.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0).

This post does not have any comments. Be the first to leave a comment below.

Post A Comment

You must be logged in before you can post a comment. Login now .

Featured Product

Model TR1 Tru-Trac

More advanced manufacturing and factory automation resources.

© 2010 - 2024 ManufacturingTomorrow - All Rights Reserved Powered by BTH Management

Suggestions or feedback?

MIT News | Massachusetts Institute of Technology

- Machine learning

- Social justice

- Black holes

- Classes and programs

Departments

- Aeronautics and Astronautics

- Brain and Cognitive Sciences

- Architecture

- Political Science

- Mechanical Engineering

Centers, Labs, & Programs

- Abdul Latif Jameel Poverty Action Lab (J-PAL)

- Picower Institute for Learning and Memory

- Lincoln Laboratory

- School of Architecture + Planning

- School of Engineering

- School of Humanities, Arts, and Social Sciences

- Sloan School of Management

- School of Science

- MIT Schwarzman College of Computing

Reducing industrial carbon emissions

Press contact :.

Previous image Next image

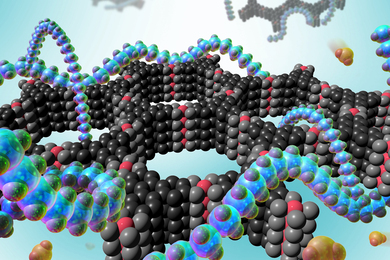

A critical challenge in meeting the Paris Agreement’s long-term goal of keeping global warming well below 2 degrees Celsius is to vastly reduce carbon dioxide (CO 2 ) and other greenhouse gas emissions generated by the most energy-intensive industries. According to a recent report by the International Energy Agency, these industries — cement, iron and steel, chemicals — account for about 20 percent of global CO 2 emissions. Emissions from these industries are notoriously difficult to abate because, in addition to emissions associated with energy use, a significant portion of industrial emissions come from the process itself.

For example, in the cement industry, about half the emissions come from the decomposition of limestone into lime and CO 2 . While a shift to zero-carbon energy sources such as solar or wind-powered electricity could lower CO 2 emissions in the power sector, there are no easy substitutes for emissions-intensive industrial processes.

Enter industrial carbon capture and storage ( CCS ). This technology, which extracts point-source carbon emissions and sequesters them underground, has the potential to remove up to 90-99 percent of CO 2 emissions from an industrial facility, including both energy-related and process emissions. And that begs the question: Might CCS alone enable hard-to-abate industries to continue to grow while eliminating nearly all of the CO 2 emissions they generate from the atmosphere?

The answer is an unequivocal yes in a new study in the journal Applied Energy co-authored by researchers at the MIT Joint Program on the Science and Policy of Global Change , MIT Energy Initiative, and ExxonMobil .

Using an enhanced version of the MIT Economic Projection and Policy Analysis ( EPPA ) model that represents different industrial CCS technology choices — and assuming that CCS is the only greenhouse gas emissions mitigation option available to hard-to-abate industries — the study assesses the long-term economic and environmental impacts of CCS deployment under a climate policy aimed at capping the rise in average global surface temperature at 2 C above preindustrial levels.

The researchers find that absent industrial CCS deployment, the global costs of implementing the 2 C policy are higher by 12 percent in 2075 and 71 percent in 2100, relative to policy costs with CCS. They conclude that industrial CCS enables continued growth in the production and consumption of energy-intensive goods from hard-to-abate industries, along with dramatic reductions in the CO 2 emissions they generate. Their projections show that as industrial CCS gains traction mid-century, this growth occurs globally as well as within geographical regions (primarily in China, Europe, and the United States) and the cement, iron and steel, and chemical sectors.

“Because it can enable deep reductions in industrial emissions, industrial CCS is an essential mitigation option in the successful implementation of policies aligned with the Paris Agreement’s long-term climate targets,” says Sergey Paltsev , the study’s lead author and a deputy director of the MIT Joint Program and senior research scientist at the MIT Energy Initiative. “As the technology advances, our modeling approach offers decision-makers a pathway for projecting the deployment of industrial CCS across industries and regions.”

But such advances will not take place without substantial, ongoing funding.

“Sustained government policy support across decades will be needed if CCS is to realize its potential to promote the growth of energy-intensive industries and a stable climate,” says Howard Herzog , a co-author of the study and senior research engineer at the MIT Energy Initiative.

The researchers also find that advanced CCS options such as cryogenic carbon capture (CCC), in which extracted CO 2 is cooled to solid form using far less power than conventional coal- and gas-fired CCS technologies, could help expand the use of CCS in industrial settings through further production cost and emissions reductions.

The study was supported by sponsors of the MIT Joint Program and by ExxonMobil through its membership in the MIT Energy Initiative.

Share this news article on:

Related links.

- Howard Herzog

- Sergey Paltsev

- Joint Program on the Science and Policy of Global Change

- MIT Energy Initiative

Related Topics

- Greenhouse gases

- Carbon dioxide

- Carbon sequestration

- Climate change

- Environment

Related Articles

Negative emissions, positive economy

Study reveals uncertainty in how much carbon the ocean absorbs over time

3 Questions: Ernest Moniz on the future of climate and energy under the Biden-Harris administration

Previous item Next item

More MIT News

Janabel Xia: Algorithms, dance rhythms, and the drive to succeed

Read full story →

Jonathan Byrnes, MIT Center for Transportation and Logistics senior lecturer and visionary in supply chain management, dies at 75

Researchers develop a detector for continuously monitoring toxic gases

The beauty of biology

Navigating longevity with industry leaders at MIT AgeLab PLAN Forum

Jeong Min Park earns 2024 Schmidt Science Fellowship

- More news on MIT News homepage →

Massachusetts Institute of Technology 77 Massachusetts Avenue, Cambridge, MA, USA

- Map (opens in new window)

- Events (opens in new window)

- People (opens in new window)

- Careers (opens in new window)

- Accessibility

- Social Media Hub

- MIT on Facebook

- MIT on YouTube

- MIT on Instagram

- Clean Energy

- Waste Management

- Ethical Fashion

Effective Strategies for Factories to Reduce Air Pollution Levels

Share post:

Have you ever wondered what it takes for factories to significantly lower their air pollution levels? As a factory manager or environmental officer, you’re likely already aware of the pressing need to reduce emissions, but finding the most effective strategies can seem like navigating through a dense fog.

This discussion will introduce a toolbox of actionable methods, from embracing clean energy to minimizing emissions at the source. While exploring these strategies, you’ll uncover how measuring progress and fostering transparency with stakeholders can improve air quality and enhance your factory’s reputation.

Embark on this journey to discover how your facility can contribute to a cleaner, healthier environment.

Key Takeaways

- Implement technology-driven solutions and optimize operations to reduce emissions effectively.

- Embrace renewable energy sources to minimize emissions at the source and enhance energy efficiency.

- Engage in continuous monitoring and compliance management to adhere to environmental regulations.

- Collaborate with experts and invest in R&D for innovative pollution control and sustainable practices.

The Choking Grip of Pollution: How Factories Can Breathe Easier

It would be best if you grasped the magnitude of industrial air pollution’s impact to tackle it effectively. Identifying sources and quantifying emissions allows you to target the most needed reduction efforts.

Implementing precise, technology-driven solutions can significantly reduce pollutants, making factories cleaner and more sustainable.

The Scope of the Problem: Understanding the Impact of Industrial Air Pollution

You must first recognize the variety of air pollutants factories release, which significantly impact both the environment and public health.

Navigating the regulatory landscape presents its compliance challenges, necessitating a strategic approach to meet these standards.

Common Air Pollutants Released by Factories

Factories release a complex cocktail of pollutants into the air, significantly impacting environmental health and human well-being.

- Particulate Matter (PM): A major contributor to air pollution, causing respiratory issues.

- Nitrogen Oxides (NOx): Industrial pollution from combustion processes contributing to smog and acid rain.

- Volatile Organic Compounds (VOCs): Emitted from solvents and paints, they form ground-level ozone, a critical air pollutant.

Reducing these emissions is crucial for cleaner air.

Environmental and Health Consequences

As we delve into the environmental and health consequences of factory emissions, it’s crucial to understand how these pollutants not only degrade our planet but also pose serious risks to public health.

Reducing air pollution from factories through renewable energy sources and controlling hazardous air pollutants like particulate matter, volatile organic compounds, and heavy metals is pivotal.

Minimizing industrial waste can safeguard human health and improve indoor air quality.

Regulatory Landscape and Compliance Challenges

Navigating the complex regulatory landscape presents significant compliance challenges for industries aiming to reduce air pollution. To empower you, here are three actionable steps:

- Implement Catalytic Technologies : Catalytic solutions can revolutionize air pollution control in industrial processes.

- Optimize Industrial Operations : Streamline operations to reduce the pollution footprint.

- Engage in Continuous Monitoring : Ensure your industrial facilities remain compliant and advance in ways factories can effectively manage emissions.

Each step offers freedom from regulatory constraints, enabling factory owners to comply and thrive, reducing air pollution from industries.

Taking Action: A Toolbox of Effective Strategies

You have the power to significantly reduce factory air pollution by implementing a set of effective strategies .

Embracing clean energy, minimizing emissions at the source, and fostering collaborative solutions are key to making a substantial impact.

These approaches enhance environmental health and improve operational efficiency in the long run.

Embracing Clean Energy

To significantly reduce factory air pollution, consider transitioning to renewable energy sources such as solar, wind, and geothermal.

Optimizing energy efficiency in your production processes can decrease emissions and save costs.

Lastly, exploring innovative technologies like carbon capture and storage presents an advanced strategy to mitigate environmental impact.

Transitioning to Renewable Sources (Solar, Wind, Geothermal)

Embracing renewable energy sources such as solar, wind, and geothermal is a pivotal strategy for factories aiming to reduce air pollution significantly.

- Solar Power : Harness the sun’s energy, consume less energy, and cut costs.

- Wind Energy : Opt for turbines to capture wind, a step towards reducing reliance on natural gas.

- Geothermal Systems : Utilize earth’s heat, offering a steady power supply and drastically reducing the amount of pollution factories produce.

Optimizing Energy Efficiency in Production Processes

Building on the foundation of incorporating renewable energy sources is crucial for factories aiming to diminish air pollution. Optimizing energy efficiency in production processes emerges as a critical step. Factories can significantly reduce environmental pollution by making processes more efficient and opting for natural energy.

Factories and other industrial operations can explore different ways to reduce pollution and align with the goals of developing countries.

Exploring Innovative Technologies like Carbon Capture and Storage

How can factories significantly cut down on their emissions?

One promising avenue is deploying innovative technologies like carbon capture and storage. These systems trap carbon dioxide and methane, less harmful compounds, before they enter our atmosphere, reducing the substances that absorb radiation from the sun and increase the planet’s temperature.

- Capture carbon dioxide from industrial activities.

- Store it safely away from the atmosphere.

- Contribute to reducing harmful emissions and combating climate change.

Minimizing Emissions at the Source

To minimize emissions at their source effectively, you must consider modernizing your equipment and adopting green processes as foundational steps.

Integrating pollution control devices, such as scrubbers and filters, can significantly reduce pollutants before they enter the environment.

Additionally, utilizing sustainable materials and implementing waste reduction programs are critical for decreasing your factory’s environmental footprint.

Modernizing Equipment and Implementing Green Processes

Upgrading outdated machinery and adopting eco-friendly procedures can significantly slash factory emissions at their origin. Here’s how you can take action:

- Modernize Equipment : Invest in newer, more efficient technology to reduce the amount of toxic materials and gases released into the environment.

- Implement Green Processes : Utilize life cycle assessments to identify and minimize emissions during production.

- Reduce Air Pollution : Focus on greener alternatives that limit the release of pollutants.

Adopting Pollution Control Devices like Scrubbers and Filters

Adopting pollution control devices like scrubbers and filters is critical in directly minimizing factory emissions at their source. These systems significantly reduce air, water, and soil pollution by capturing hazardous gases and particulates, including dioxide and toxic materials.

They’re essential for industrial factories aiming to lower health and environmental risks and reduce water consumption associated with pollution control.

Utilizing Sustainable Materials and Waste Reduction Programs

Implementing sustainable materials and waste reduction programs can significantly lower factory emissions by targeting the problem at its core.

- Choose Sustainable Materials : Many factories can also build factories with less environmental impact by selecting materials that reduce the damage caused.

- Analyze Costs and Benefits : Assessing the balance between investing involves risk and the potential for reducing emissions.

- Implement Waste Reduction : Chemical plants, a major contributor, can minimize the continued damage by adopting waste minimization strategies.

Collaborative Solutions

You’ll find that forging partnerships with industry experts and environmental organizations can significantly amplify your efforts to reduce factory air pollution.

You’re fostering a supportive ecosystem and driving meaningful change by engaging with local communities and advocating for clean air policies.

Investing in research and development for next-generation solutions also ensures you’re at the forefront of innovative practices that can further mitigate emissions.

Partnering with Industry Experts and Environmental Organizations

To effectively reduce factory air pollution, it’s crucial to establish partnerships with industry experts and environmental organizations, leveraging their knowledge and resources for innovative solutions.

- Transition from fossil fuels, like oil to natural gas, optimizing energy efficiency.

- Explore nuclear power options, offering cleaner alternatives to traditional energy sources.

- Implement technological advancements that have been around for centuries, enhancing them for modern environmental challenges.

Engaging with Local Communities and Advocating for Clean Air Policies

Engaging with local communities and advocating for stringent clean air policies are crucial to combating factory air pollution .

Don’t get caught at the end of the production cycle with outdated methods. Collaboration ensures your strategies remain relevant and effective, avoiding penalties.

Investing in Research and Development for Next-Generation Solutions

Investing in research and development (R&D) propels factories towards innovative, next-generation solutions to reduce air pollution significantly.

- Develop Cleaner Technologies : Focus on creating technologies that emit less pollutants.

- Enhance Efficiency : Aim for processes that use fewer resources and produce less waste.

- Adopt Renewable Energy : Shift towards energy sources that don’t contribute to air pollution, enhancing your factory’s sustainability.

These steps ensure you’re at the forefront of environmental stewardship.

Measuring Progress and Inspiring Change

You’ll need to accurately assess your factory’s impact by tracking emissions and monitoring air quality.

Ensuring reporting and transparency with stakeholders bolsters trust and fosters a culture of accountability.

Analyzing case studies of successful sustainable factories can guide your strategy and inspire significant change.

Tracking Emissions and Monitoring Air Quality

Effective emissions tracking and rigorous air quality monitoring are crucial steps in measuring the environmental impact of factories and inspiring industry-wide change. You’re tasked with a significant responsibility, but with the right tools and strategies, you can lead your factory to comply with regulations and become a beacon of environmental stewardship.

To focus your efforts, consider these three actions:

- Implement Continuous Emission Monitoring Systems (CEMS) : These systems provide real-time pollutant data, allowing immediate adjustments.

- Adopt Air Quality Monitoring Stations : These stations track ambient air quality around your facility, ensuring community safety.

- Utilize Predictive Analytics : Leverage data analytics to forecast potential emission spikes, enabling preemptive measures.

Reporting and Transparency with Stakeholders

To measure progress and inspire change, your factory must maintain robust reporting and transparency practices with all stakeholders. By doing so, you’re demonstrating accountability, building trust, and fostering a culture of continuous improvement.

You should regularly share detailed emissions data, reduction targets, and progress reports. This approach enables stakeholders to see the direct impact of your efforts, encouraging further investment and support in your environmental initiatives.

Moreover, adopting a transparent communication strategy empowers your community and workforce, making them active participants in your sustainability journey. It’s about showing tangible results and setting a benchmark for others in the industry. Remember, transparency isn’t just about sharing successes; it’s also about being open about challenges and how you’re addressing them, thereby inspiring collective action towards cleaner air.

Case Studies: Success Stories of Sustainable Factories

Examining real-world examples, let’s explore how some factories have successfully implemented sustainable practices, significantly reducing their environmental footprint.

- Renewable Energy Adoption : A textile factory in India switched to solar power for 60% of its energy needs, slashing carbon emissions by 40%. This move cut costs and set a benchmark for the industry, inspiring others to follow suit.

- Waste Heat Recovery Systems : A steel plant in Sweden installed advanced waste heat recovery systems, utilizing excess heat for district heating. This innovation cut their greenhouse gas emissions by 25%, demonstrating a profitable pathway to sustainability.

- Closed-loop Water Recycling : In the United States, a beverage manufacturing plant implemented a closed-loop water recycling process, reducing its water consumption by 50%. This approach conserved water and minimized the plant’s overall environmental impact, showcasing how operational efficiency can align with ecological preservation.

Frequently Asked Questions

1. how do local weather patterns influence the effectiveness of air pollution reduction strategies in factories.

Local weather patterns greatly impact how well your factory’s pollution reduction efforts work. For example, high winds can disperse pollutants, while temperature inversions trap them, demanding more adaptive and flexible strategies to ensure effectiveness.

2. Can Implementing Air Pollution Reduction Strategies in Factories Lead to Significant Improvements in Public Health Outcomes in Nearby Communities?

Absolutely, by adopting air pollution reduction strategies, you’re directly contributing to enhanced public health in surrounding communities. It leads to fewer respiratory issues, decreased healthcare costs, and a significant boost in community well-being.

3. What Are the Long-Term Economic Impacts on Factories That Invest Heavily in Cutting-Edge Air Pollution Control Technologies?

When you invest in advanced air pollution control technologies, you’re looking at an initial financial outlay. However, over time, these investments often lead to savings on operational costs and can boost your factory’s competitive edge.

4. How Can Factories Collaborate With Local Governments and Communities to Create More Comprehensive Air Quality Improvement Plans?

You can partner with local governments and communities to draft comprehensive air quality plans by sharing data, funding joint projects, and engaging in public forums. This collaboration ensures everyone’s voice is heard in the solution.

5. Are any successful case studies of Factors in heavily polluted areas that have dramatically reduced their emissions while maintaining or even increasing their production levels?

Yes, some factories have reduced emissions significantly without sacrificing production. They’ve implemented cleaner technologies and energy-efficient processes, showing that you can maintain economic growth while protecting the environment.

LEAVE A REPLY Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Revolutionizing Sustainability: The Rise of Recycling Superbags

Effective ways to prevent litter and pollution in your city, top 10 reasons to go green: the benefits of green living for the environment and business, eco-friendly ways to dispose of cooking oil: safe and effective methods, a resource digest for people considering ecopreneurship, planning an elegant eco-friendly wedding: style meets sustainability, related articles, dissecting the disadvantages of hybrid cars on the environment, the ban on gas-powered car sales by 2035: a paradigm shift in the automotive industry, the untold truth about why plastic bags shouldn’t be banned, applying technology to combat pollution in the ocean.

- Privacy Policy

- Terms of Use

Copyright © 2021 fritzenergy.com All Rights Reserved All Logos & Trademark Belongs To Their Respective Owners.

Policy Hub » US Federal

Controlling industrial greenhouse gas emissions, at-a-glance.

- Nearly 30 percent of U.S. greenhouse gas emissions come from industry, including indirect emissions from the sector’s electricity consumption.

- Oil and gas production is the largest manmade source of methane in the United States.

- In January 2021, President Biden issued an Executive Order directing federal agencies to review actions taken during the previous administration.

Almost a quarter (23 percent) of U.S. greenhouse gas emissions come directly from industrial sources, such as manufacturing, food processing, mining, and construction. These direct emissions result from diverse processes, including the on-site combustion of fossil fuels for heat and power, non-energy use of fossil fuels, and chemical processes used in iron, steel, and cement production.

In addition, industry generates indirect emissions from the centrally generated electricity it consumes. The industrial sector makes up about one quarter of total U.S. electricity sales. If direct and indirect emissions are combined, the industrial sector is the largest emitting sector in the U.S. economy, responsible for 29.6 percent of total emissions.

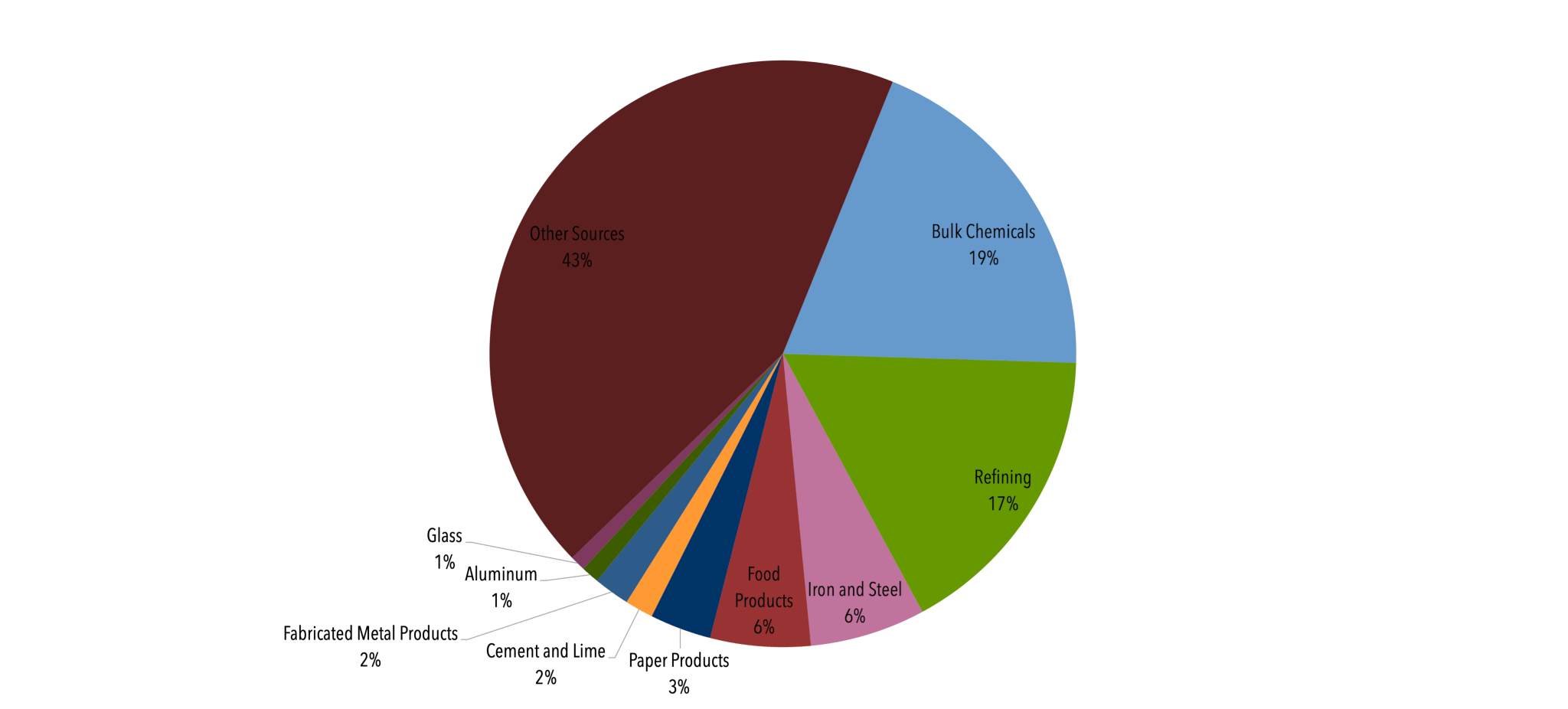

Energy-related carbon dioxide emissions from industry, 2020

Source: Annual Energy Outlook (U.S. Energy Information Administration, 2021)

Reducing Industrial Emissions

There are many ways to reduce greenhouse gas emissions from the industrial sector, including energy efficiency, fuel switching, combined heat and power, use of renewable energy, and the more efficient use and recycling of materials. Many industrial processes have no existing low-emission alternative and will require carbon capture and storage to reduce emissions over the long term.

Hydrofluorocarbons (HFCs) — chemicals widely used in refrigeration, air conditioning, foam blowing, and other applications — are the fastest-growing greenhouse gases. With a global warming potential thousands of times greater than carbon dioxide, HFCs can have a significant impact on climate change. Given their high emissions rates and relatively short atmospheric lifetimes (compared to carbon dioxide), efforts to reduce HFC emissions in the near term will significantly reduce projected temperature increases over the coming decades.

The American Innovation and Manufacturing Act of 2020 directs EPA to implement an 85-percent phasedown of the production and consumption of regulated HFCs over a 15-year period, manage these HFCs and their substitutes, and facilitate the transition to next-generation technologies. EPA is required to issue regulations for the HFC phasedown within 270 days after enactment (by September 16, 2021).

Oil and Gas Production

Oil and gas production is the United States’ largest manmade source of methane, the second biggest driver of climate change. In the production process, methane can leak unintentionally. It also can be intentionally released or vented to the atmosphere for safety reasons at the wellhead or to reduce pressure from equipment or pipelines.

In January 2021, President Biden issued Executive Order 13990, Protecting Public Health and the Environment and Restoring Science to Tackle the Climate Crisis , directing federal agencies to review actions taken in the last four years. Among many other things, the Executive Order calls on the EPA to consider suspending or revising a 2020 technical amendment to the new source performance standards (NSPS) for the oil and gas sector by September 2021. In addition, the Executive Order calls on EPA to consider proposing regulations for methane and volatile organic compounds (VOCs) from existing operations in the oil and gas sector by September 2021.

In June 2021, Congress voted to repeal the 2020 methane rule under the Congressional Review Act and the resolution was signed into law by President Biden. The measure restores the more stringent 2016 methane rule.

In August 2020, EPA issued two amendments (i.e., the 2020 methane rule) that effectively rescinded the 2016 oil and gas new source performance standards (NSPS) under Section 111(b) of the Clean Air Act. These amendments removed transmission and storage segments from covered oil and gas source categories, rescinded NSPS applicable to those sources, and rescinded methane-specific requirements for the production and processing segments under Section 111(b) of the Clean Air Act. In the amendments, EPA declared that there are no emissions impacts or potential costs from removing the methane requirements for new, reconstructed, and modified sources in the production and processing segments. The EPA justified the amendments with the claim that the current methane limits are redundant with the NSPS volatile organic compounds (VOCs) requirements in the production and processing segments (e.g., fugitive emissions, pneumatic controllers, pneumatic pumps, and compressors).

Operators new oil and gas wells must now follow the 2016 methane rule, which required them to find and repair leaks and capture natural gas from the completion of hydraulically fractured oil and gas wells. They must also limit emissions from new and modified pneumatic pumps, and from several types of equipment used at natural gas transmission compressor stations, including compressors and pneumatic controllers. When it issued the rule in 2016, EPA estimated it could prevent the emission of 510,000 short tons of methane in 2025 (the equivalent of 11 million metric tons of carbon dioxide) in addition to reducing other harmful air pollutants such as volatile organic compounds (VOCs, which are ozone-forming pollutants).

Regardless of the regulatory approach, EPA continues to work with industry and states through its voluntary Natural Gas STAR program to reduce methane from existing oil and gas operations.

In addition, Executive Order 13990 would require the Department of Interior to review a 2018 rule that rescinded the 2016 methane emissions rule from wells on lands managed by the Bureau of Land Management and Indian lands. The 2016 rule placed the first limits on flaring natural gas and increased disclosure requirements. Furthermore, it prohibited venting except in specified circumstances, required pre-drill planning for leak reduction, and increased use of leak-detection technology.

Other Industrial Sources

Other industrial sectors, such as refineries and cement kilns, have been regulated for certain pollutants, including particulate matter (PM), sulfur dioxide (SO2), and dioxides of nitrogen (NOx), since the Clean Air Act became law in 1970.

Section 111 of the act requires the regulation of pollution from new, modified, and reconstructed facilities through the New Source Performance Standards (NSPS) program. NSPS are technology-based standards that apply to specific categories of stationary sources. NSPS for pollutants are regularly strengthened by EPA to safeguard human health and the environment as technology advances and new pollution controls become more economically feasible. The Clean Air Act requires EPA to establish New Source Performance Standards for greenhouse gas emissions from all significant emitting subsectors, as clarified in the U.S. Supreme Court case Massachusetts v. EPA .

Related Content

Tags Industry Regulation

Federal Vehicle Standards

Tags Transportation Regulation

U.S. Emissions

Tags Emissions

Other Resources

- Sources of Greenhouse Gas Emissions, U.S. EPA

4 solutions to help reduce carbon emissions from industrial clusters

Focused action in European industrial clusters can reduce carbon emissions by up to 12% Image: Marco de Winter / Unsplash

.chakra .wef-1c7l3mo{-webkit-transition:all 0.15s ease-out;transition:all 0.15s ease-out;cursor:pointer;-webkit-text-decoration:none;text-decoration:none;outline:none;color:inherit;}.chakra .wef-1c7l3mo:hover,.chakra .wef-1c7l3mo[data-hover]{-webkit-text-decoration:underline;text-decoration:underline;}.chakra .wef-1c7l3mo:focus,.chakra .wef-1c7l3mo[data-focus]{box-shadow:0 0 0 3px rgba(168,203,251,0.5);} Roberto Bocca

Stephanie jamison.

.chakra .wef-9dduvl{margin-top:16px;margin-bottom:16px;line-height:1.388;font-size:1.25rem;}@media screen and (min-width:56.5rem){.chakra .wef-9dduvl{font-size:1.125rem;}} Explore and monitor how .chakra .wef-15eoq1r{margin-top:16px;margin-bottom:16px;line-height:1.388;font-size:1.25rem;color:#F7DB5E;}@media screen and (min-width:56.5rem){.chakra .wef-15eoq1r{font-size:1.125rem;}} SDG 09: Industry, Innovation and Infrastructure is affecting economies, industries and global issues

.chakra .wef-1nk5u5d{margin-top:16px;margin-bottom:16px;line-height:1.388;color:#2846F8;font-size:1.25rem;}@media screen and (min-width:56.5rem){.chakra .wef-1nk5u5d{font-size:1.125rem;}} Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:, sdg 09: industry, innovation and infrastructure.

- Industrial clusters can play a major role in helping countries achieve their net-zero ambitions.

- Accenture and the World Economic Forum have developed a 4-step framework to help clusters reduce carbon emissions.

- This approach could result in a decline of up to 40% of European industrial emissions by 2030.

Countries representing 70% of the global economy have committed to net-zero emissions targets by 2050 – and major energy ecosystems such as industrial clusters will play a pivotal role in helping these countries meet their climate goals.

Industrial clusters are geographic areas encompassing co-located companies that represent either a single industry (chemical parks, for example) or multiple industries (such as steel and cement). Examples of large industrial clusters around the world include the Humber Cluster in the UK, Suzhou Industrial Park in China and the Port of Rotterdam in the Netherlands.

Have you read?

Industrial clusters are critical to getting to net-zero. here’s why, how to finance industry's net-zero transition, 4 ways to build a net-zero economy by 2050, an integrated approach to reducing carbon emissions in industrial clusters.

Accenture, in collaboration with the World Economic Forum, has developed a framework built around four key solutions to help reduce carbon emissions in industrial clusters:

1. Systemic efficiency and circularity

2. direct electrification and renewable heat, 3. hydrogen.

4. Carbon capture, utilization and storage (CCUS)

Adopting these solutions could result in a decline of up to 40% of European industrial carbon emissions by 2030 (up to 12% of overall European emissions). The key is approaching this through multi-stakeholder collaboration and in an integrated manner.

Energy efficiency and circularity are common industry themes – but we can push these concepts much further. For example, Meishan, a hub for logistics and high-tech industries in China, has set an ambitious target of carbon neutrality by around 2050. To achieve this and similar targets, multi-stage resource utilization will be a key area of focus. One example could involve recovering the cooling load from a liquified natural gas (LNG) terminal to support a freezer warehouse, and the subsequent recovery of this cooling to support a snow park.

The economics of clean electricity and the need to recover on past asset investments has limited the electrification of industrial processes. However, around half of industrial carbon emissions are derived from light or medium industries such as food processing or equipment manufacturing; these use low and medium-temperature processes that can be electrified using commercially available technology. The attractiveness of electrification is rising due to the falling cost of renewables, higher carbon pricing and shared infrastructure such as microgrids. For example, Suzhou Industrial Park in China has implemented an all-in-one microgrid solution that provides power, cooling and heating as required.

Hydrogen can help reduce carbon emissions in hard-to-abate sectors such as steel and chemicals. Applications include hydrogen as a feedstock for products and in chemical reactions as well as high value uses in certain forms of transport and power storage. Industrial clusters can create an internal market for hydrogen, where production and consumption are co-located. For example, the Spanish electricity company Iberdrola, in partnership with fertilizer manufacturer Fertiberia, will build one of the largest green hydrogen production plants in 2021. Iberdrola will supply solar PV electricity to power an electrolyzer that will provide green hydrogen, which will in turn be used in Fertiberia’s production plant, resulting in significant carbon emissions reductions.

4. Carbon capture, utilization and storage

Major CCUS hubs are emerging across the globe, providing alternatives for industries struggling to reduce carbon emissions. However, given the sizeable investments in transport and storage required to implement CCUS, such projects require a certain amount of scale to be feasible. Industrial clusters can provide this scale given the concentration of heavy industry and therefore the aggregation of demand. For example, the UK expects to capture and store up to 10 million tonnes of CO2 by 2030 via projects such as those at the Humber industrial cluster in the North of England, where an onshore pipeline is being developed to collect captured CO2 from multiple carbon abatement projects in the region. The captured CO2 will then be transported offshore and stored under the seabed of the North Sea.

Moving from intention to action to reduce carbon emissions

Policy and regulatory support for measures such as reflective carbon prices and carbon border adjustment mechanisms will help improve the competitiveness of low carbon or carbon-neutral initiatives.

Government support may also need to include capital for large-scale infrastructure projects and new ways of working.

Beyond policy and financing, the adoption of low-carbon technologies in clusters can create wider system value benefits such as job creation and economic development, air quality improvements and subsequent human health benefits, as well as the creation of a digitally enabled modern integrated energy system that is more secure and resilient.

Multi-stakeholder collaboration

Companies in industrial clusters already have a long history of collaboration when it comes to sharing resources, challenges and solutions. But there is a new driving force for co-location: net-zero commitments at the national level.

The opportunity to reduce carbon emissions in industrial clusters is significant. The time to act is now. New partnerships, combined with new approaches to policy, financing and scaling of technologies will be key to accelerating the transition to a net-zero economy. These partnerships and approaches will be built on the pillars of greater multi-stakeholder collaboration and greater trust.

What are the next steps? Companies in new and existing industrial clusters will need to come together and align on common net-zero goals, followed by the development and implementation of clear roadmaps that set out how to achieve these targets. Putting in the effort now will help us to ensure a cleaner, greener and more prosperous future.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The agenda .chakra .wef-n7bacu{margin-top:16px;margin-bottom:16px;line-height:1.388;font-weight:400;} weekly.

A weekly update of the most important issues driving the global agenda

.chakra .wef-1dtnjt5{display:-webkit-box;display:-webkit-flex;display:-ms-flexbox;display:flex;-webkit-align-items:center;-webkit-box-align:center;-ms-flex-align:center;align-items:center;-webkit-flex-wrap:wrap;-ms-flex-wrap:wrap;flex-wrap:wrap;} More on Energy Transition .chakra .wef-17xejub{-webkit-flex:1;-ms-flex:1;flex:1;justify-self:stretch;-webkit-align-self:stretch;-ms-flex-item-align:stretch;align-self:stretch;} .chakra .wef-nr1rr4{display:-webkit-inline-box;display:-webkit-inline-flex;display:-ms-inline-flexbox;display:inline-flex;white-space:normal;vertical-align:middle;text-transform:uppercase;font-size:0.75rem;border-radius:0.25rem;font-weight:700;-webkit-align-items:center;-webkit-box-align:center;-ms-flex-align:center;align-items:center;line-height:1.2;-webkit-letter-spacing:1.25px;-moz-letter-spacing:1.25px;-ms-letter-spacing:1.25px;letter-spacing:1.25px;background:none;padding:0px;color:#B3B3B3;-webkit-box-decoration-break:clone;box-decoration-break:clone;-webkit-box-decoration-break:clone;}@media screen and (min-width:37.5rem){.chakra .wef-nr1rr4{font-size:0.875rem;}}@media screen and (min-width:56.5rem){.chakra .wef-nr1rr4{font-size:1rem;}} See all

Critical minerals demand has doubled in the past five years – here are some solutions to the supply crunch

Emma Charlton

May 16, 2024

How wind energy is reshaping the future of global power and politics

Rishabh Mishra

May 14, 2024

Boosting renewable energy growth through responsible value chains: A case study from China

Vee Li and Zhang Xun

May 13, 2024

4 strategies to decarbonize existing buildings

Jesse Saldivar, Alaina Ladner, Marc Starkey and Brittany Syz

Why realism is key as we balance the energy transition with global growth

Fahad Al-Dhubaib

May 10, 2024

How to finance battery energy storage and ensure constant clean energy

Prasad Thakur and Labanya Prakash Jena

Do something for our planet, print this page only if needed. Even a small action can make an enormous difference when millions of people do it!

All official European Union website addresses are in the europa.eu domain.

Try our suggestions

The challenge of reducing industrial pollution.

- Bulgarian (bg)

- German (de)

- English (en)

- Spanish (es)

- French (fr)

- Croatian (hr)

- Hungarian (hu)

- Italian (it)

- Polish (pl)

- Slovak (sk)

- Swedish (sv)

- Turkish (tr)

We can categorise pollution by where we find it — in air, water or soil — or we can look at different pollution types, such as chemicals, noise or light. Another way to look at pollution is to go to its sources. Some pollution sources are spread out, such as cars, agriculture and buildings, but others can be better assessed as individual emission points. Many of these point sources are large installations, such as factories and power plants.

Industry is a key component of Europe’s economy. According to Eurostat, in 2018, it accounted for 17.6 % of gross domestic product (GDP) and directly employed 36 million people. At the same time, industry also accounts for more than half of the total emissions of some key air pollutants and greenhouse gases, as well as other important environmental impacts, including the release of pollutants to water and soil, the generation of waste and energy consumption.

Air pollution is often associated with the burning of fossil fuels. This obviously applies to power plants but also to many other industrial activities that may have their own onsite electricity or heat production, such as iron and steel manufacturing or cement production. Some activities generate dust that contributes to particulate matter concentrations in the air, whereas solvent use, for example in metal processing or chemical production, may lead to emissions of polluting organic compounds.

Industrial air emission trends

Air emissions from industry in Europe have decreased over recent years. Between 2007 and 2017, overall emissions of sulphur oxides (SO x ) declined by 54 %, nitrogen oxides (NO x ) by more than one third and greenhouse gases from industry, including power plants, by 12 % [ The European environment — state and outlook 2020 , pp. 274-275].

These improvements in environmental performance by European industry have occurred for a number of reasons, including stricter environmental regulation, improvements in energy efficiency, a move towards less polluting types of manufacturing processes and voluntary schemes to reduce environmental impact.

For many years, environmental regulation has limited the adverse impacts of industrial activities on human health and the environment. Key EU measures targeting industrial emissions include the Industrial Emissions Directive, which covers about 52 000 of the largest industrial plants, and the Medium Combustion Plants Directive.

The EU Emissions Trading System (EU ETS), meanwhile, limits greenhouse gas emissions from more than 12 000 power generation and manufacturing installations in 31 countries. The EU ETS covers around 45 % of the EU’s greenhouse gas emissions.

However, despite these improvements, industry is still responsible for a significant burden on our environment in terms of pollution and waste generation.

Public accountability — the E-PRTR and transparency of industrial emissions data

The European Pollutant Release and Transfer Register (E-PRTR) was set up in 2006 to enhance public access to environmental information.

In essence, the E-PRTR enables citizens and stakeholders to learn about pollution in all corners of Europe, who the top polluters are and whether or not pollutant emission trends are improving.

The E-PRTR covers more than 34 000 facilities across 33 European countries. E-PRTR data show, for each facility and year, information concerning the amount of pollutants released to air, water and land, as well as off-site transfers of waste and pollutants in waste water. E-PRTR data are freely available on a dedicated, interactive website . The website archives historical data on releases and transfers of 91 pollutants across 65 economic activities.

Moreover, the E-PRTR is now integrated with wider reporting under the Industrial Emissions Directive, including further information for large combustion plants . Together with the European Commission, the EEA is currently working on a new website to improve access to these data and information.

Counting the costs of industrial air pollution

In order to account for the external costs of air pollution, an individual pollutant’s adverse impacts on human health and the environment are expressed in a common metric, a monetary value, which has been developed through cooperation between different scientific and economic disciplines.

Damage cost estimates are just that — estimates. However, when considered alongside other sources of information, they can support decisions by drawing attention to the implicit trade-offs in decision‑making, such as the cost-benefit analyses used to inform impact assessments and subsequent legislation.

The EEA estimated in 2014 that the aggregated cost of damage over the 5-year period 2008-2012 caused by emissions from E-PRTR industrial facilities was at least EUR 329 billion (2005 value) and rising . What is perhaps even more striking in this analysis is that about half of the damage costs occurred as a result of emissions from only 147, or 1 %, of the 14 000 facilities in the data set.

The majority of the quantified damage costs is caused by emissions of the main air pollutants and carbon dioxide. Although damage cost estimates associated with heavy metal and organic pollutant emissions are significantly lower, they still cause hundreds of millions of euros in harm to health and the environment and can cause significant adverse impacts on the local scale. The EEA is currently working on a new study that will update these figures.

Reducing industrial pollution — assessment, legislation and implementation

The EEA regularly assesses trends in industrial pollution in Europe based on E-PRTR and other data. These assessments show that industrial pollution has decreased over the past decade for emissions to both air and water. Existing and incoming EU policy instruments are expected to further reduce industrial emissions, but pollution is likely to continue to have adverse impacts on human health and the environment in the future.

A strong, growing, low-carbon industry based on circular material flows is part of the EU industrial policy strategy . The goal is to create a growing industrial sector that draws less and less on natural resources, reduces pollutant emissions to air, water and land, and generates decreasing amounts of waste.

Meanwhile, other EU legislation sets more concrete air emission reduction targets, such as the National Emission Ceilings Directive and the Industrial Emissions Directive , which aim to achieve the ambitious prevention and reduction of emissions, in particular through the continuous uptake of so-called best available techniques (BATs).

According to a recent EEA analysis , using best available techniques and implementing the more ambitious targets of the Industrial Emissions Directive would result in substantial emission reductions: 91 % for sulphur dioxide, 82 % for particulate matter and 79 % for nitrogen oxides.

Fully implementing these directives would help the EU achieve environmental objectives, such as those on air and water quality. However, the emission-related directives often act independently and there is clear scope for further integration of the environmental objectives into the EU’s industrial policy. Moving towards zero pollution will require even more robust legislation, implementation and monitoring to ensure that the industries of tomorrow are both clean and sustainable.

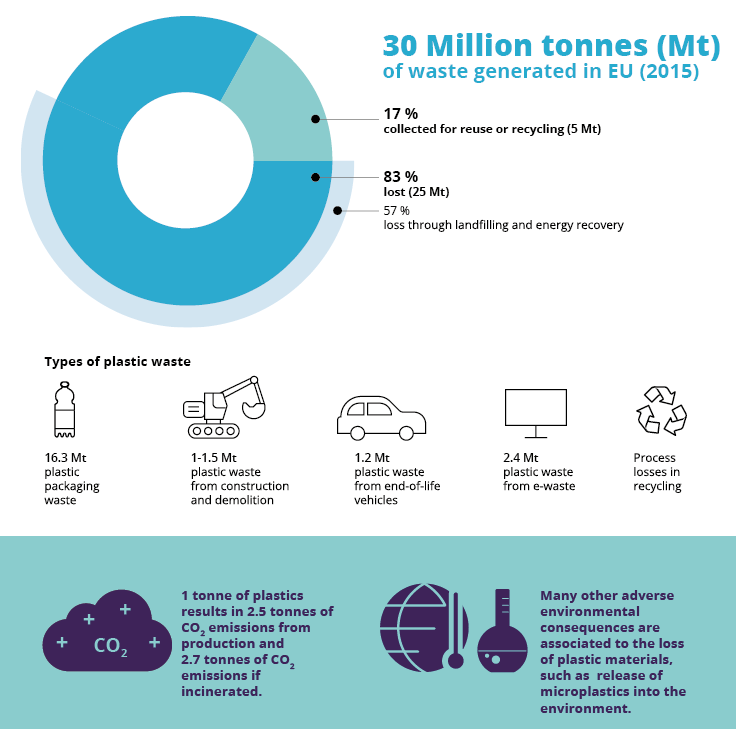

Plastic pollution

Plastics have brought many benefits to our daily lives but the problem is that these products never truly disappear. Therefore, we should perhaps think about plastics as a type of pollutant from the point of their production and prevent plastic products and waste from leaking into the environment.

Source: Reducing loss of resources from waste management is key to strengthening the circular economy in Europe ; EEA Infographic .

Find out more

Industry: www.eea.europa.eu/themes/industry

SOER 2020, Chapter 12 on industrial pollution: www.eea.europa.eu/publications/soer-2020/chapter-12_soer2020-industrial-pollution/view

Related content

Related briefings, related infographics, related publications, geographic coverage, temporal coverage.

For references , please go to https://www.eea.europa.eu/signals-archived/signals-2020/articles/the-challenge-of-reducing-industrial-pollution or scan the QR code.

PDF generated on 18 May 2024, 11:43 AM

Document Actions

Share with others.

Engineered by: EEA Web Team

Software updated on 26 September 2023 08:13 from version 23.8.18

Software version: EEA Plone KGS 23.9.14

Code for developers

Systems Status

Legal notice

Creative commons license

- Air & Climate

- Drinking Water

- Environmental Management

- Health & Safety

- Monitoring & Testing

- Soil & Groundwater

- Waste & Recycling

- Water & Wastewater

- Water Monitoring

- Water Pumping

- Air & Climate

- Acid Gas Emissions Control

- Activated Carbon Air Treatment

- Activated Carbon Gas Treatment

- Activated Carbon Treatment

- Activated Carbon VOC Treatment

- Aerobiology

- …and more

- Applications

- Atmospheric Water Generation

- Bottled Water

- Bottleless Water

- Communal Water

- Developing Countries Water

- Domestic Drinking Water

- Acoustic Bird Control

- Air Modeling

- Air Quality Reporting

- Aquatic Waste Collectors

- Archaeology

- Asbestos Compliance

- Health & Safety

- Absorbent Polymers

- Accident Compliance

- Accident Monitoring

- Accident Regulations

- Accidental Release

- Acid Safety

- Monitoring & Testing

- 3D Measurement

- 3D Scanning

- Absorptiometers

- Absorption Monitoring

- Accelerometers

- Acetonitrile Monitoring

- Soil & Groundwater

- 3D Groundwater

- Acid Mine Drainage

- Airborne Geophysics

- Anaerobic Bioremediation

- Aquifer Characterization

- Aquifer Monitoring

- Waste & Recycling

- Acid Recycling

- Acoustic Cleaning

- Aerobic Biodegradation

- Aerobic Waste

- Aerosol Cans Disposal

- Water & Wastewater

- Acidic Wastewater Treatment

- Activated Carbon Filtration

- Activated Carbon Water Treatment

- Activated Sludge

- Activated Sludge Monitoring

- Air and Water Quality Monitoring

- Algae Bloom Monitoring

- Aquatic Monitoring

- Automatic Water Sampling

- Ballast Water Monitoring

- Axial Pumps

- Backwashing Pumps

- Balancing Valve

- Booster Pumps

- Cavity Pumps

- … and more

- Environmental XPRT Search

- List your business

- Email marketing

- Oizom Instruments Pvt. Ltd.

- How do Factories Cause Air Pollution?

How do Factories Cause Air Pollution ?

Courtesy of Oizom Instruments Pvt. Ltd.

The modern world, bathed in the conveniences of industrialisation, is paradoxically paying the price for its advancements. The factories that once symbolised progress and prosperity have now, to some extent, become synonymous with environmental degradation.

This isn’t merely a topic for debate in academic circles; it’s a tangible, pervasive issue that impacts the air we breathe, the health of our global population, and the ecosystems that sustain life on Earth. This article comprehensively exposes the intricate relationship between factories and air pollution, interspersed with hard-hitting data, industry insights, and forward-thinking solutions.

The labyrinth of industrial processes is diverse and expansive, resulting in various pollutants that adversely affect air quality.

One of the linchpins of industrial operations, fossil fuels, are a double-edged sword. While they power a significant portion of global factories, the combustion of coal, oil, and natural gas has environmental repercussions that are hard to ignore. Carbon dioxide (CO2) , a primary greenhouse gas, is emitted in vast quantities.

With the industrial sector accounting for approximately 21% of global CO2 emissions, the scale of the problem is evident. Add to this mix other gases like methane, which is over 25 times more potent at trapping heat over 100 years than CO2, and the environmental ramifications are severe.

Moreover, the release of nitrogen oxides and sulphur dioxide culminates in the formation of smog and acid rain, both deleterious effects on ecosystems.

Beyond fossil fuels, the industrial realm involves a myriad of chemical processes. Petrochemical plants, pharmaceutical factories, and agro-based industries, among others, release a spectrum of chemicals into the atmosphere.

As emitted from paint factories or refineries, VOCs don’t just remain as isolated pollutants. They interact with other atmospheric emissions, resulting in secondary pollutants like ground-level ozone , a major respiratory irritant and a significant contributor to urban smog.

While the Industrial Age has ushered in an era of unprecedented growth, it has also witnessed some of history’s most tragic industrial accidents. Instances like the Bhopal gas tragedy aren’t mere historical footnotes but stark reminders of the devastating impact of unbridled toxic emissions.

Factories dealing in heavy metals, chemical solvents, and radioactive materials have the potential to release substances that can persist in the environment, leading to long-term health issues and ecological imbalances.

Dust might seem innocuous, but in the industrial context, it’s anything but. Industries such as mining or construction produce copious amounts of particulate matter (PM) . This PM, especially the ultra-fine PM2.5, can penetrate deep into the lungs, causing respiratory and cardiovascular issues.

With industry-related PM accounting for a significant portion of airborne particulates, the scale and gravity of this issue are palpable.

The ripple effects of factory pollution aren’t confined merely to the immediate vicinity of the emission source. They stretch far and wide, affecting both the intricate web of ecosystems and the holistic well-being of human populations across the globe.

As the world continues its tryst with industrialisation, public health stands at the crossroads of progress and pollution. The International Agency for Research on Cancer (IARC) and the World Health Organization (WHO) have consistently identified certain industrial pollutants as carcinogens. Besides cancer, long-term exposure to pollutants like benzene, asbestos, and even certain heavy metals can lead to respiratory diseases, cardiovascular issues, and even neurodegenerative conditions.

Children, in particular, are especially vulnerable. Growing bodies are more susceptible to airborne pollutants. For instance, childhood asthma has sharply risen in many developing nations, directly correlating with proximity to industrial areas. The elderly, especially those with pre-existing conditions, are also at increased risk. Heart attacks, strokes, and chronic obstructive pulmonary disease (COPD) have all been linked to industrial pollutants.

The environment, our collective shared space, bears the cumulative impact of decades of industrial activity. Ecosystems, from the lush rainforests of the Amazon to the Great Barrier Reef coral reefs, all feel the sting of pollution. Acid rain, formed due to the reaction of sulphur dioxide and nitrogen oxides with water vapour, doesn’t merely affect aquatic ecosystems. It alters soil pH, affecting agriculture and forest covers. The increasing acidity of oceans, a direct result of CO2 emissions, poses an existential threat to marine biodiversity.

But the environmental narrative isn’t just about individual species or habitats. It’s about the grand tapestry of biodiversity. Pollinators like bees are affected by pollutants, decreasing pollination and affecting global food chains. With industrial emissions contributing significantly to global warming, melting polar ice caps lead to rising sea levels, threatening coastal habitats and human settlements.

The United States, with its vast industrial landscape, stands as both a beacon of industrial progress and a case study of environmental repercussions. However, it’s a dynamic tableau marked by evolving policies, emerging technologies, and a renewed commitment to sustainability.

The past few decades have seen transformative environmental policies like the Clean Air Act, which mandated strict emission standards and significantly reduced pollutants like lead, carbon monoxide, and ozone. However, challenges persist. The coal industry, once the backbone of the American energy matrix, has faced scrutiny due to its environmental footprint. While there’s been a marked shift towards renewable energy, pockets of resistance and economic considerations pose challenges to a complete transition.

Moreover, the intricate web of federal and state regulations occasionally leads to disparities in implementation and enforcement. For instance, while California leads with its stringent emission norms, other states might need to catch up, leading to a patchwork of environmental outcomes.

In the face of such challenges, the silver lining is the emergence of sustainable, eco-friendly measures underpinned by technological innovation and green ethos.

Green building standards are no longer niche; they’re becoming the norm. Factories are being designed with energy efficiency in mind, using sustainable materials and processes that minimise waste. Carbon capture and storage (CCS) technologies are seeing increased adoption, trapping emissions before they reach the atmosphere.

Moreover, the circular economy ethos is gaining traction. Waste, instead of being discarded, is viewed as a resource. By-products from one industry become inputs for another. For instance, the ash residue from coal plants, rich in minerals, is being used in road construction and other sectors.

The rise of Industry 4.0, marked by the Internet of Things (IoT), artificial intelligence, and big data analytics, allows factories to monitor emissions in real-time, tweaking processes to minimise their carbon footprint.

Understanding factory-induced air pollution is akin to traversing a complex mosaic of history, science, economics, and ethics. While the challenges posed by decades of industrial activity are daunting, the collective human endeavour points towards a future that harmonises progress with sustainability.

Oizom, at the forefront of this paradigm shift, provides comprehensive solutions that empower industries to monitor, assess, and act. The path to industrial sustainability becomes clearer with real-time data, cutting-edge technology, and a commitment to a greener future.

Harness the power of data with Oizom’s air quality monitors. Elevate your industry’s environmental commitment. Dive deeper here.

Most popular related searches

- air pollution

- carbon capture and storage

- air quality monitoring

- rising sea level

- capture and storage

- air quality monitor

- CO2 emissions

- heavy metals

- Placeholder

Customer comments

No comments were found for How do Factories Cause Air Pollution? . Be the first to comment!

Great! comment successfully added!

The captcha is not valid

Russell Millner/Alamy

Defend Our Planet and Most Vulnerable Species

Your donation today will be triple-matched to power NRDC’s next great chapter in protecting our ecosystems and saving imperiled wildlife.

Air Pollution: Everything You Need to Know

How smog, soot, greenhouse gases, and other top air pollutants are affecting the planet—and your health.

- Share this page block

What is air pollution?

What causes air pollution, effects of air pollution, air pollution in the united states, air pollution and environmental justice, controlling air pollution, how to help reduce air pollution, how to protect your health.

Air pollution refers to the release of pollutants into the air—pollutants that are detrimental to human health and the planet as a whole. According to the World Health Organization (WHO) , each year, indoor and outdoor air pollution is responsible for nearly seven million deaths around the globe. Ninety-nine percent of human beings currently breathe air that exceeds the WHO’s guideline limits for pollutants, with those living in low- and middle-income countries suffering the most. In the United States, the Clean Air Act , established in 1970, authorizes the U.S. Environmental Protection Agency (EPA) to safeguard public health by regulating the emissions of these harmful air pollutants.

“Most air pollution comes from energy use and production,” says John Walke , director of the Clean Air team at NRDC. Driving a car on gasoline, heating a home with oil, running a power plant on fracked gas : In each case, a fossil fuel is burned and harmful chemicals and gases are released into the air.

“We’ve made progress over the last 50 years in improving air quality in the United States, thanks to the Clean Air Act. But climate change will make it harder in the future to meet pollution standards, which are designed to protect health ,” says Walke.