Diagram Tool

Business Use

Individual Use

6M Fishbone Analysis: Diagram Definition, Explanation, and Templates

There are benefits of using quality tools such as 6M analysis for an individual or organization. The primary purpose of having a 6M analysis is to identify the cause and effect of why an event is happening through a diagram. Managers, organizations, or even typical individuals utilize this tool to overview the situation. With it, you can look at the problems in multiple ways to gain clarity and make wise decisions.

Bear in mind that a single cause may fall into various categories. Speaking of categories, it allows you to rank and separate the specific causes for an in-depth overview of the effects and problems. In this case, the 6M fishbone approach is of great help. In this post, you will have a deep understanding of what 6M analysis is, how it is valuable, and how you can make one for your decision-making. Keep reading to get the needed information.

Cause & Effect Analysis - 6M

Want to create a fishbone diagram? Design Now!

EdrawMax Fishbone Diagram Maker helps to create specialized fishbone diagram with ease. You can edit the built-in template and design it in your own style. Just give it a shot.

Part 1: What is 6M/6M's?

Part 2: how to use 6m in cause and effect analysis, part 3: examples of 6ms, part 4: definition of 4m/5m/8m.

- Part 5: More Cause and Effect Diagram Examples [Free Templates Download]

Part 6: Conclusion

6M/6M's is a mnemonic tool used primarily used when it comes to problem-solving or decision making. The Cause and Effect diagram , also known as Fishbone Diagram, proves extremely beneficial when exploring or dissecting any production or industrial operations problems. It is a problem-solving technique that identifies the likely causes of a challenge and undertakes to fix it.

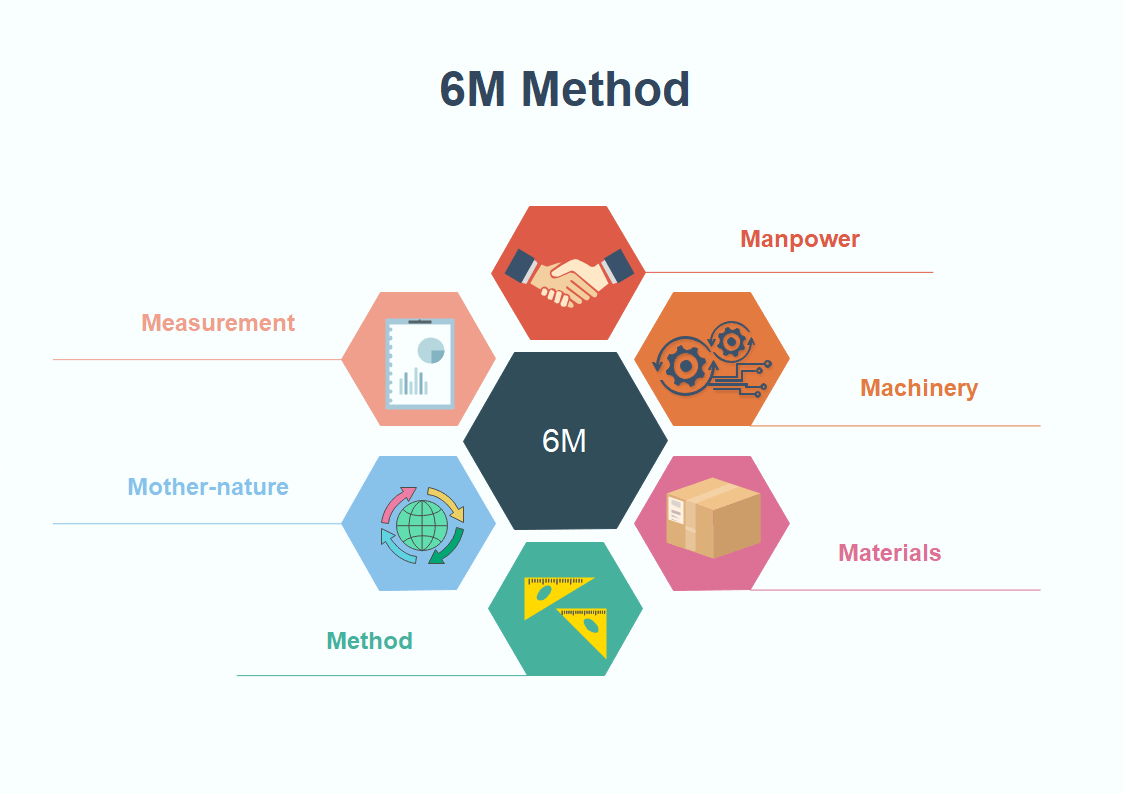

The 6M method encourages people to explore problems in multiple ways.

*If you want to know more cause and effect diagram directly, please click here .

Click here to see the HD version of the template.

1. Download 6M Method template by clicking here for free.

2. Use EdrawMax fishbone diagram maker to open and use this 6M Method template . Download from the button below.

6M method is based on the following parameters:

- Manpower : Revolves around the operational and functional labor of people involved in the industry's processes. This parameter checks on whether the personnel's technical proficiency and experience are up to standard. Whether the staff has quality consciousness, sense of responsibility and discipline are answered by this 6M method aspect.

- Machinery : Touches on machines, tools, and other facilities together with their underlying support systems. Is the machinery employed for production capable of delivering the intended output? Are machines and tools well-managed to achieve excellence?

- Material : Raw materials, components, and consumables management to satisfy production and service delivery. This parameter checks on the correct specification of materials, their proper storage, labeling, and subsequent usage.

- Method : Production and support processes and their application or contribution to service delivery. Does any of the methods relied on in your processes have too many steps and integral activities that don't add value to the whole system?

- Mother-nature : Considers both controllable and unpredictable environmental influences in the operation processes. Weather and other natural events fall into this category. It makes it easy to take note of the many environmental factors that are manageable under ardent considerations and how to handle those that are not.

- Measurement : Inspection, evaluation, and other physical measures – whether manual or automatic. Staying keen about calibration errors and other measurement challenges to avoid inconsistencies becomes important under this parameter.

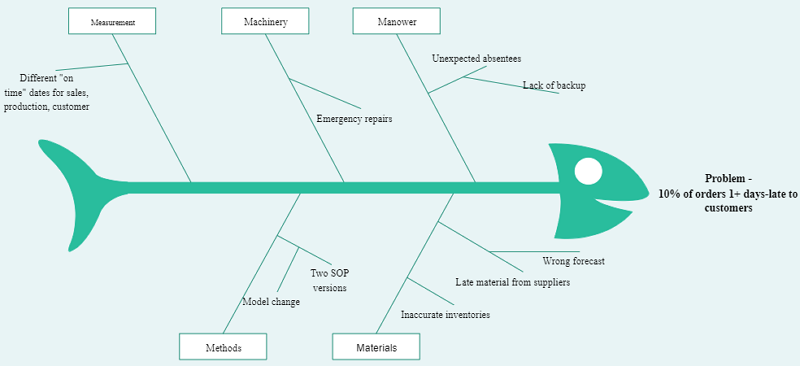

The 6M Method in Ishikawa Diagram centers on a problem and explores its prospective causes to solve it and foster wholesome operations. Also known as Fishbone Diagram (due to its appearance) or Ishikawa Diagram (named after its developer), the mnemonic representation of the characteristic dimensions to contemplate when brainstorming is indisputably significant during problem-solving sessions. The 6M Method encourages the capturing and assorting of challenging issues under the 6M categories.

Click on the picture to see more fishbone diagram templates.

Once an issue is captured and documented, the causes are placed according to the Cause and Effect diagram categories. This model encourages management to view problems in multiple ways. Classifying the causes shouldn't plunge you into indecisiveness. When a single cause seems to fall into different categories, take a quick vote where to group the cause and move on improvement plans.

Improvement plans you agree on should start with the most significant issues first. The 6M Ishikawa Diagram plays an important role here as it helps separate the causes and improvement plans into categories and even rank them in terms of importance.

Efficient Fishbone Diagram Maker >>

- Superior file compatibility: Import and export drawings to various file formats, such as Visio

- Cross-platform supported (Windows, Mac, Linux, Web)

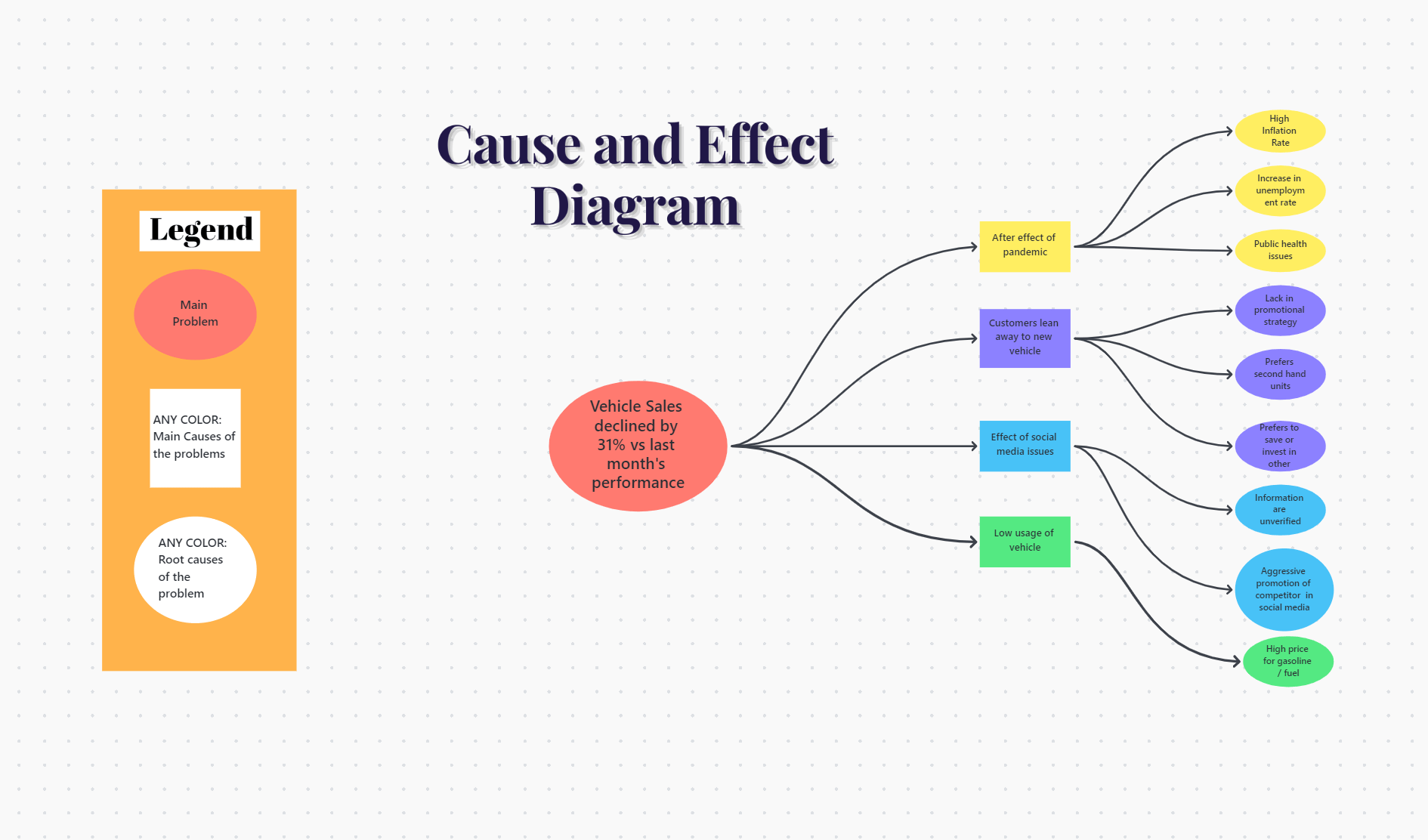

The 6Ms in Cause and Effect Analysis is a multi-facet approach to solving every organization’s or industry’s problem by subjecting it to thorough and balanced considerations. The following examples depict how useful the method can prove in solving issues for smooth operations.

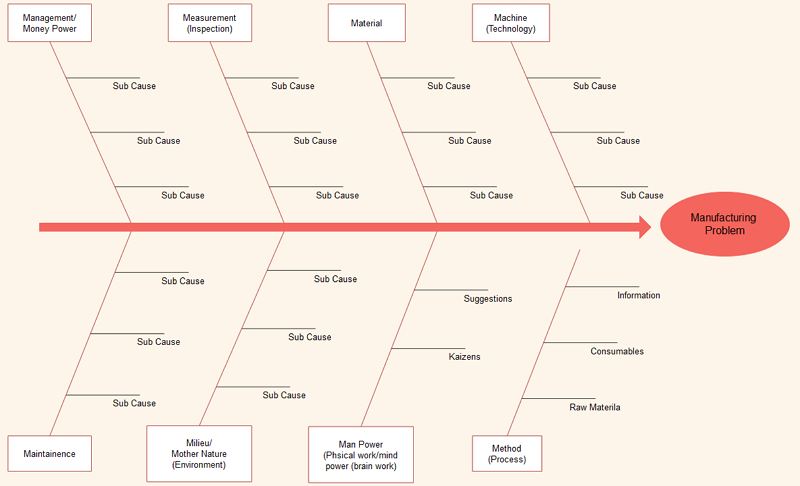

6Ms in Manufacturing

- Method : Specific regulations or policies causing slow-downs in processes.

- Mother Nature (Environment) : There is too much moisture in the environment; Temperatures are too cold affecting other production processes

- Manpower (People Power) : Training new people adequately; Ensuring training is consistent.

- Measurement : The equipment is regularly calibrated and maintained to avoid errors in calculations or contaminations that result in false readings.

- Machine : Maintenance issues with tools used and the number available for operations.

- Materials : Any issues are getting raw materials from suppliers or transport challenges recorded—problems with the quality of supplies.

6Ms in Marketing

- Market : Identify the target market to achieve marketing goals while saving costs and time.

- Message : The right message that differentiates your brand among its competitors.

- Media : Which media and mechanism would be most successful in getting your message out?

- Money : With the market and message to be communicated clearly defined and the medium to pass information outlined, set a budget for marketing and allocate money.

- Manage : Execute your plan. Everyone involved should have a plan with set timelines to get everything done.

- Measurement : Monitor the results from all your marketing efforts and streamline the whole process to consistently yield the right number and type of leads.

4M is a typical structure utilized in problem-solving methods by first pointing potential causes of production issues. Most organizations are familiar with this concept that makes every associate a confident problem-solver within a firm.

The 4Ms stand for Man (Manpower), Machine, Material and Method. Refer to their illustrations above. Other M's have sometimes been added to the full effect of the Ishikawa Diagram.

5M Method is based on five causes. This version of the Fishbone Diagram is a versatile method used to identify causes or risks, inefficiency, low quality, and other business processes issues. It adds the Management aspect to 4Ms.

The problem causes in the 8M Cause and Effect Analysis diagram are often categorized as Man (Manpower), Machine, Material, Method, Management, Mother Nature (Environment), Measurement, and Maintenance. The 8ms lists factors or causes all affecting the main problem in one drawing for in-depth analysis.

Part 5: More Cause and Effect Diagram Examples

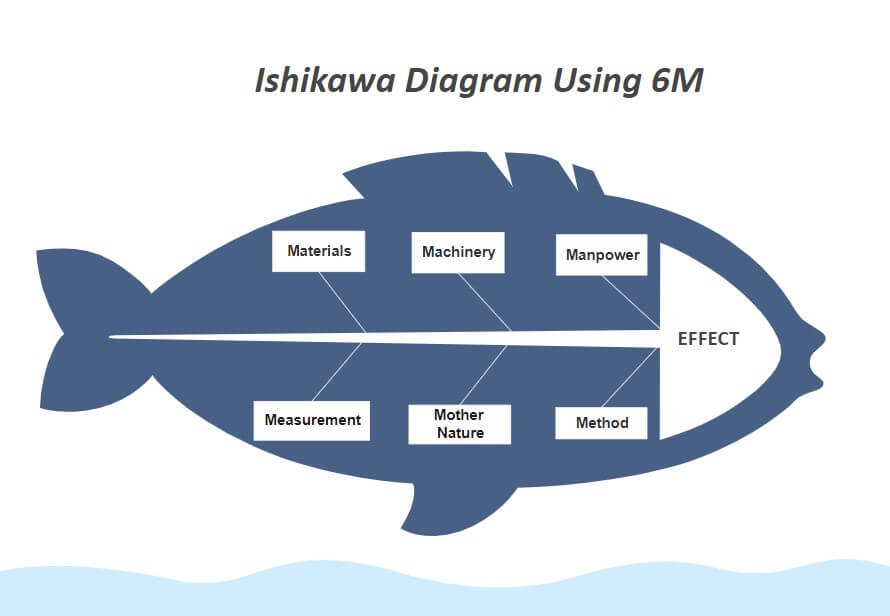

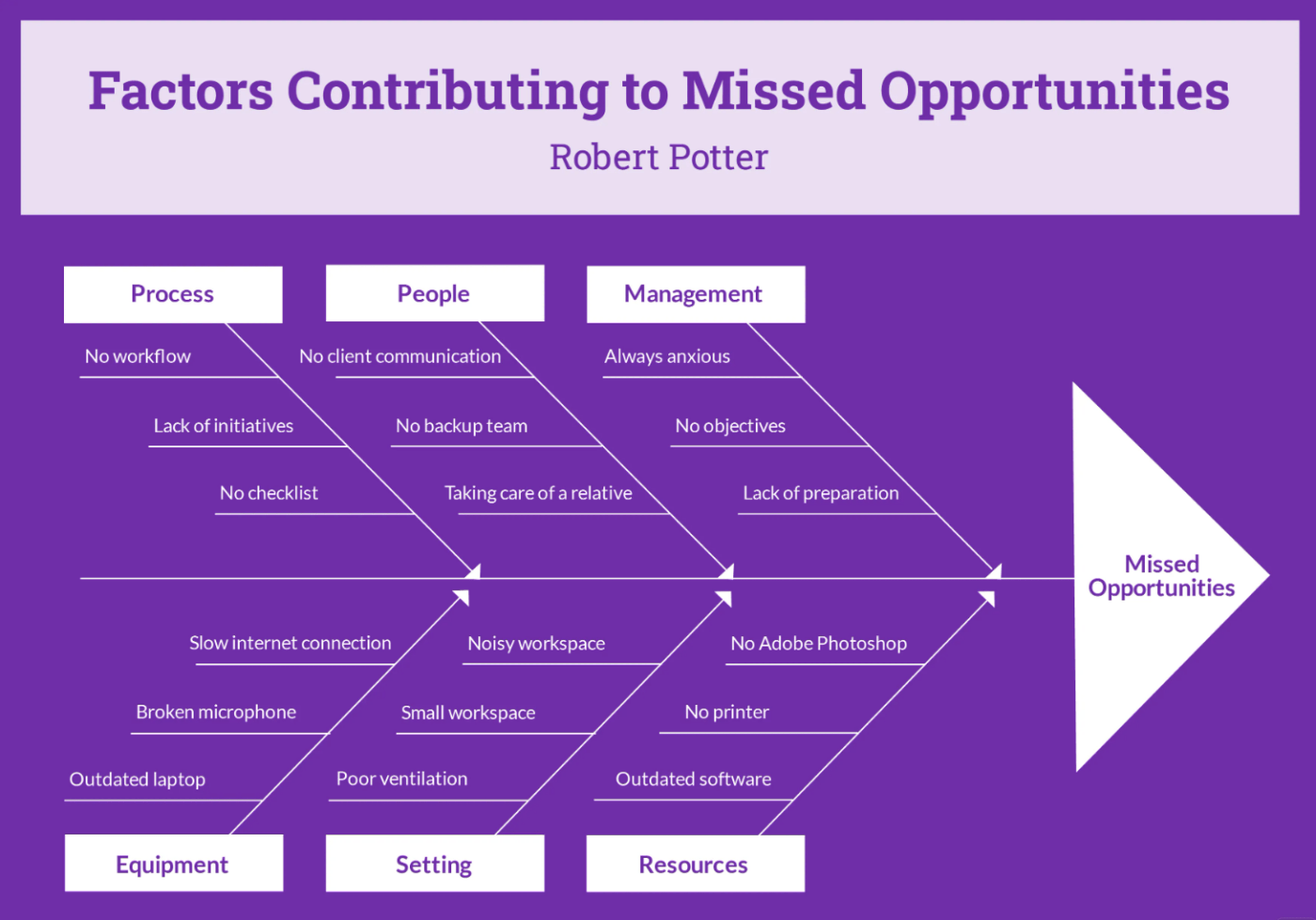

Example 1: Ishikawa Diagram Using 6M

Ishikawa diagram examines a broad set of possible causes of a problem for the issue to be analyzed. These are referred to as the 6Ms – Methods, Machines, Materials, Measurements, Mother Nature, and Manpower in the manufacturing industry.

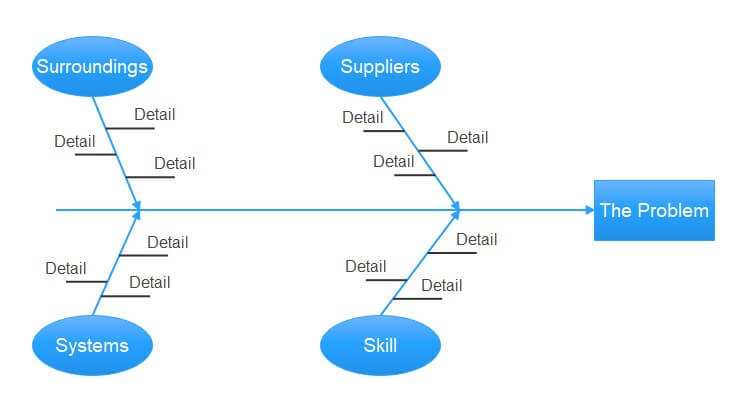

Example 2: 4S Model

In the service industry, the categories are mostly referred to as 4S:

Surroundings – Is your firm projecting the right image? Is it impersonal?

Suppliers – Do you have any problems with low-quality material deliveries? Are there any issues delivering service?

Systems – Are there good policies and procedures in place for all scenarios?

Skill – Do employees have adequate experience? Are they adequately trained?

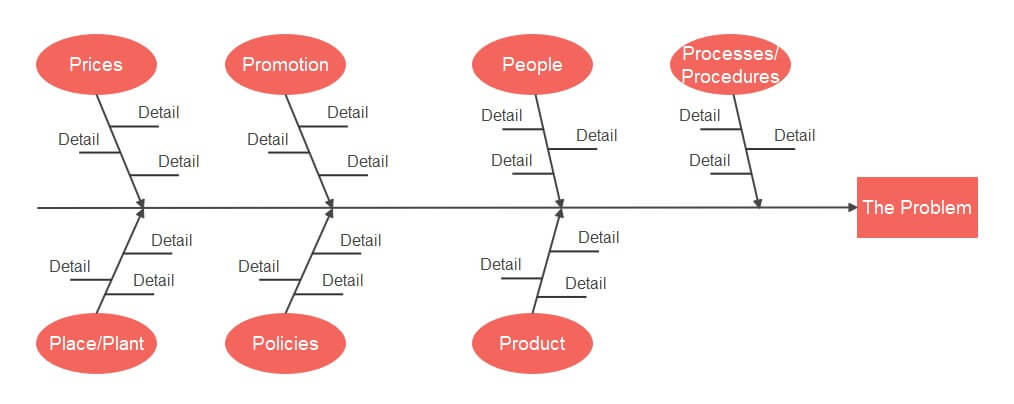

Example 3: 7Ps Model

In the marketing industry, the Cause and Effect diagram often consists of 7Ps. These relate to Product, People, Process/Procedure, Promotion, Price, Packaging, and Plant.

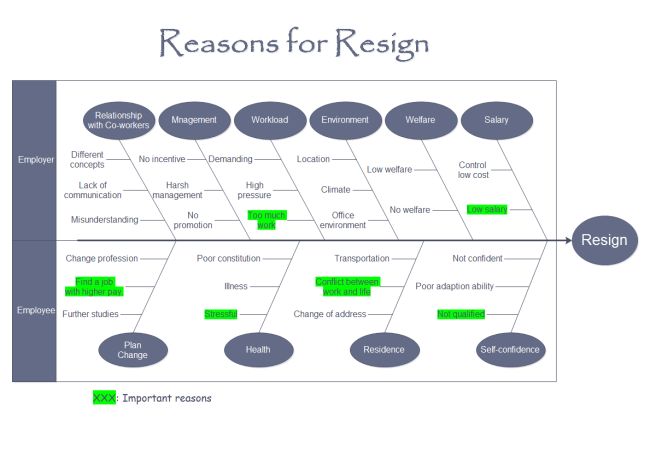

Example 4: Reasons for Employee Resignation

In this Cause and Effect diagram example, we have tried to diagnose the various reasons for an employee’s resignation.

Apart from the 6 major factors, we have considered other scenarios like salary, work environment, health, residence, management, workload, and other factors. All these factors have been further explored, considering the possible causes for employee resignation and their effects.

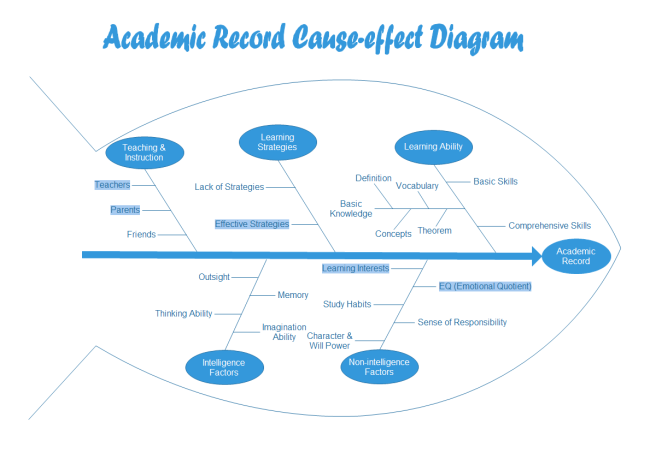

Example 5: Results of an Academic Record

In next Cause and Effect diagram, you can explore the numerous possibilities for one’s academic results. In this, we have considered things like one’s learning abilities, teaching, learning strategies as well as intelligent and non-intelligent factors that can affect their result.

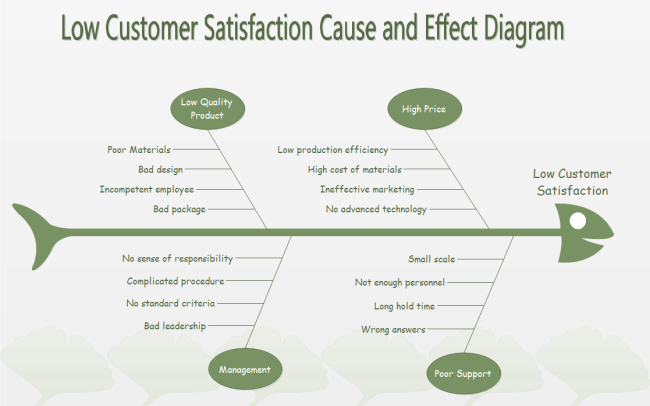

Example 6: Low Customer Satisfaction Fishbone Diagram

Lastly, you can check the Cause and Effect diagram for low customer satisfaction. Ideally, things like high price, low-quality product, poor customer support, and management are some of the major causes of the lack of customer satisfaction. All these causes are further explored in this Low Customer Satisfaction fishbone diagram.

That’s a wrap, everyone! After reading this post, you would be able to know more about the Cause and Effect analysis in detail. To help you come up with informative Cause and Effect diagrams, I have included the 6M analysis plan as well. You can also work on any Cause and Effect diagram by using a reliable and user-friendly diagramming tool like EdrawMax .

Cause and Effect Diagrams make it easy to examine a problem in production or service delivery processes by organizing the potential causes into smaller categories. Thus, it becomes simpler understanding the relationship between contributing factors. The best practices in Fishbone Diagram entail identifying the problem, brainstorming, drawing the backbone, adding causes and effects, analyzing the information to come to solutions fortified by creating action items.

One of the best ways to gain from 6M insights is by using the 6Ms approach as a spine on the Fishbone Diagram and then ask the five why's to narrow down the potential root cause. Remember the 6 elements contribute to variation in all processes, but none of the M's is unduly influencing the process when you have a bell-shaped curve.

More Related

How to Create a Cause and Effect Diagram

Cause and Effect Diagram Examples

5W1H Method

Get Started! You Will Love This Easy-To-Use Diagram Software

EdrawMax is an advanced all-in-one diagramming tool for creating professional flowcharts, org charts, mind maps, network diagrams, UML diagrams, floor plans, electrical diagrams, science illustrations, and more. Just try it, you will love it!

Understanding the 6Ms: A Powerful Tool for Root Cause Analysis

Updated: September 18, 2023 by Ken Feldman

The 6Ms is a tool that helps you search for the root causes of a problem. The 6Ms are the possible process inputs that you might evaluate and assess in the hopes that, by addressing one or more of them, you will be able to improve your process. In this article, we will define the 6Ms, present a number of variations on this approach, describe the benefits of using the 6M approach, and provide a few hints on how you can successfully use this tool.

Overview: What are the 6 Ms?

The 6Ms and other similar variations are a tool you can use to categorize your process inputs. The 6Ms are usually used in the context of looking for and finding the possible root cause of your process variation or problems. It’s flexible enough that you can use it in any functional area across myriad applications.

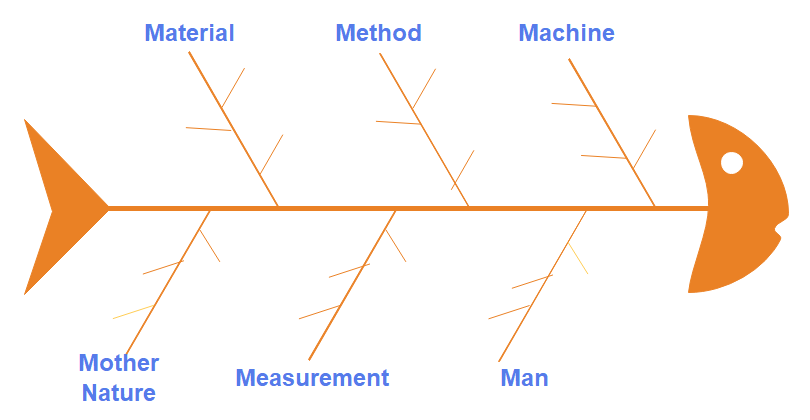

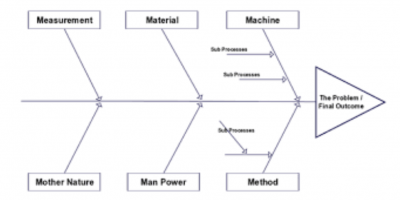

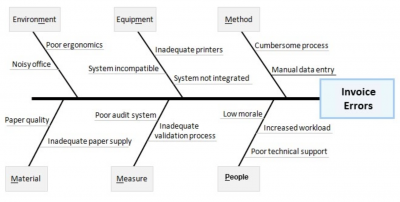

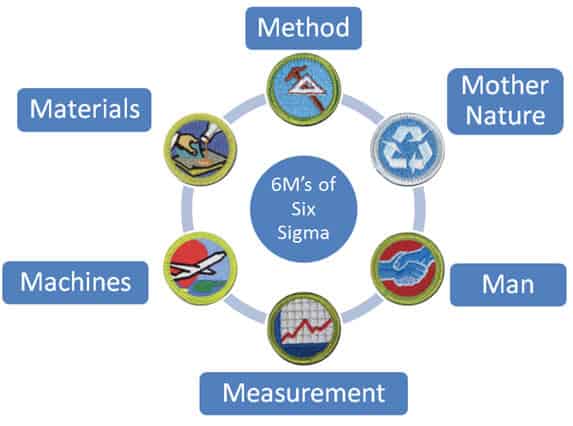

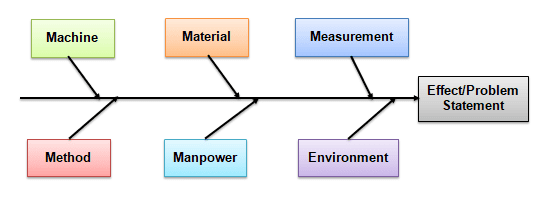

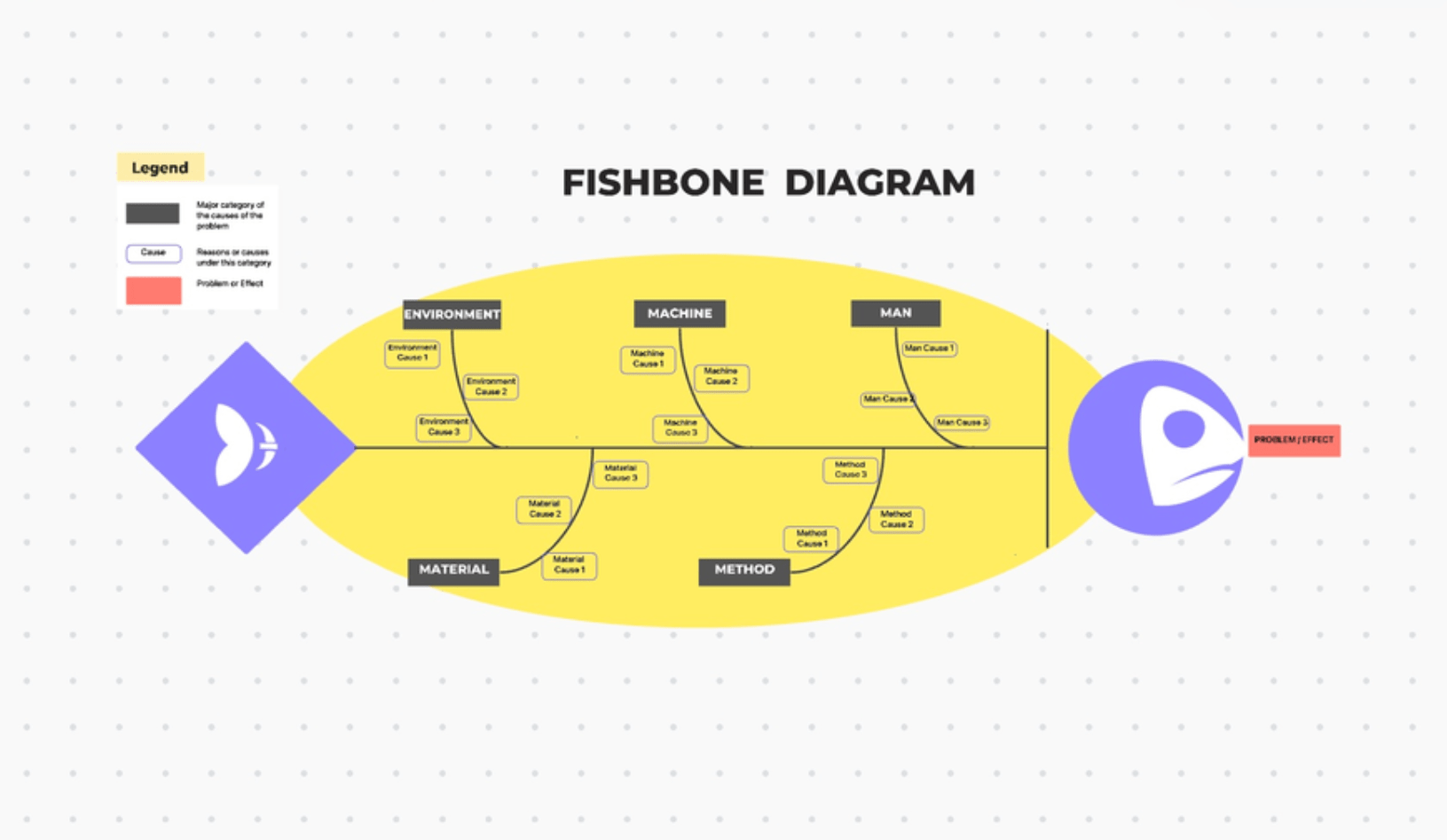

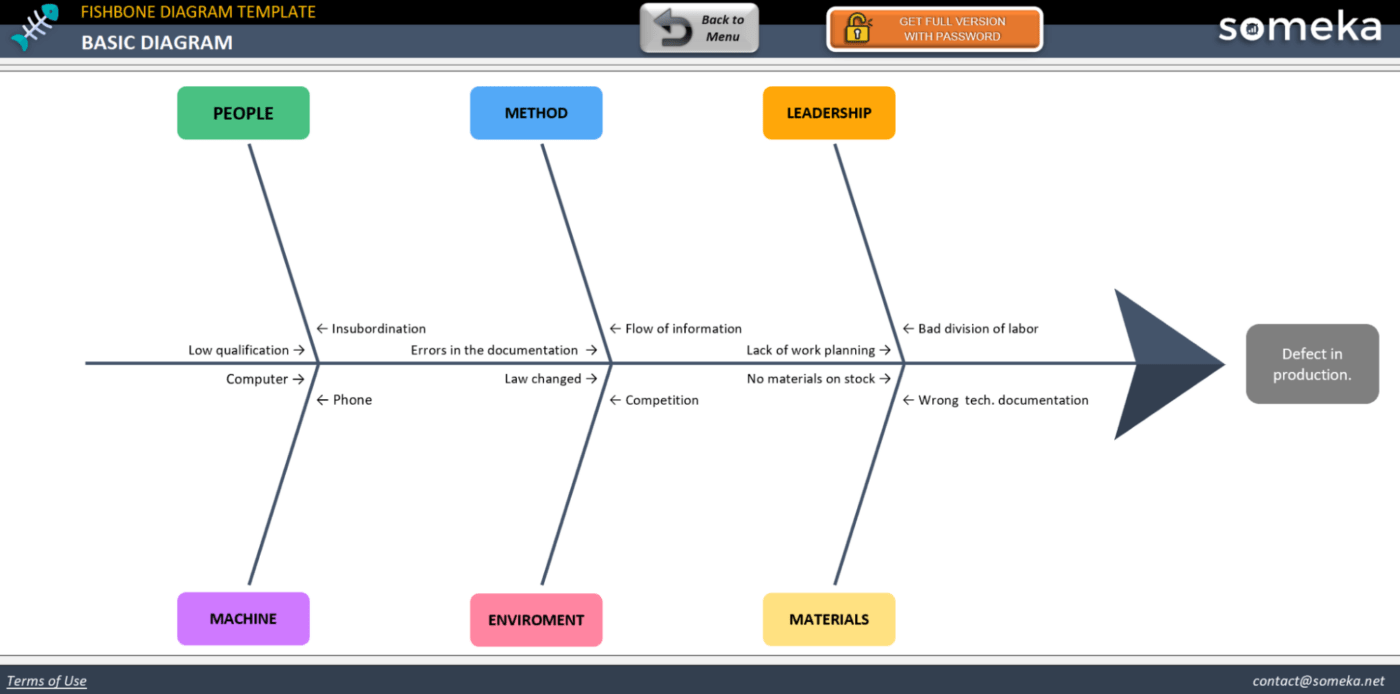

The format in which you use it will usually be the cause and effect diagram , also known as the Fishbone Diagram or Ishikawa Diagram . The standard format for these diagrams is:

Image source: M udamasters.com .

Although you will see the 6Ms in different sequences, the definition of the Ms will be the same. The 6Ms are:

- Method: The process steps you need to produce an output or deliver a service.

- Machinery: Machines and tools that you need to produce an output or deliver a service.

- Material: The raw materials, consumables, or assemblies that you need to produce the output or deliver the service.

- Manpower: The people in your process.

- Measurement: Data, KPIs, inspection results and any other measures that you take of the process inputs, transformation process, and process outputs.

- Mother Nature: Environmental conditions both controllable or random that you have both internal and external to your process.

In some versions of the 6Ms, you will see the word “Milieu” used instead of Mother Nature. While the 6Ms might be a great mnemonic to remember the process elements, today you will often see the 6Ms represented as 3Ms, 2Es, and 1P, which are described as: Method, Equipment, Material, People, Measurement, and Environment. Or you might see the 5Ms and one P where the Machinery and Mother Nature are kept, but Manpower becomes People. Despite the variation in terms and the possible confusion, you can see that the concepts and elements are consistent.

You will also see the use of the 5Ms where Mother Nature is dropped from the list. In Marketing, the 6Ms may be defined as: Market, Message, Media, Money, Manage, and Measurement. In the 8Ms version you might see Management and Maintenance added to the list of 6Ms.

While you will frequently use the Fishbone diagram in a manufacturing environment, the concept of root cause analysis can apply to non-manufacturing and transactional processes as well. Since Machinery and Material may not be as applicable to a non manufacturing process, you might see the use of People, Policies, Processes, Training, and Communication as the primary bones of the Fishbone Diagram.

Regardless of the words used to describe the process elements, the methodology and approach to searching for root causes remains the same.

3 benefits of using the 6 Ms

The simplicity of your use of the 6Ms to search for root causes makes this a very beneficial approach for a number of reasons.

Provides a framework

One of the first steps you do when creating a Fishbone Diagram is brainstorming . The 6Ms provides the format and context for what you want to focus on in your brainstorming.

Gives focus

During a root cause analysis, you may find yourself diverting to topics and discussions that are not relevant to the problem at hand. The use of the 6Ms give you a basis for reining in that discussion and staying on task.

Allows for a deeper dive

One of the critical steps in doing root cause analysis is to continue to ask the question “what causes that?” This drilling down is what gets you to the real root cause. By drilling down under each of the Ms, you will increase your probability of finding the true root cause.

Why are the 6 Ms important to understand?

The 6Ms are the most common format for doing root cause analysis. To properly use a Fishbone Diagram and do root cause analysis, you will want to understand what they mean and how to drill down under each of the Ms.

Basis for doing root cause analysis

The 6 Ms are the most commonly used terms in the context of doing root cause analysis with a Fishbone or Ishikawa diagram.

Provides broad perspective

The root cause of a process problem may be due to a combination of factors. By using all 6 Ms for your analysis, you will cover the range of the most likely sources of why something in the process is not working as it should.

Simplicity of use

The 6Ms can take a complex problem and break it down into a small number of categories and make it simpler for you to understand the relationship between the process inputs and variables.

An industry example of the 6 Ms

The Director of Sales for a large machinery manufacturer noticed an increase in the number of customer complaints about incorrect invoicing coming from the Billing department. Although the company had previously used the 6Ms approach to address manufacturing issues, the Billing department decided to use it for one of their recurring problems. Since most of the employees in the department were female using computers, they decided to change a few titles of the 6Ms by changing Machinery to Equipment, Manpower to People and Mother Nature to Environment.

The team first hung up a large piece of butcher paper on the wall and handed out a package of sticky notes to everyone. The first step was to define the problem in the head of the fish. Using their sticky notes, they brainstormed the possible causes of each M and wrote those on the diagram.

Drilling down under each M was the next step of the process. The first-level causes and subsequent second-level causes were organized in a hierarchical sequence. Once the same cause started to appear on multiple branches or Ms, they realized that they possibly had their root cause.

They collected some data to confirm that these were the root causes. The team then developed mitigation and improvement recommendations to reduce the number of invoice errors.

3 best practices when thinking about the 6 Ms

Your use of the 6Ms in the context of root cause analysis and a Fishbone Diagram is conceptually simple. There are a few best practices that will help you make your efforts more efficient and productive.

1. Relevancy

Be sure the terminology of the 6Ms fits the nature of your problem and root cause analysis. This will be more important if you are applying the technique to a non-manufacturing problem.

2. Keep drilling down

You will rarely uncover the root cause associated with the 6Ms during your first pass of possible causes. Keep drilling down until the same potential cause starts to appear under multiple M branches.

3. Keep an open mind

When you brainstorm your possible root causes, remain open and nonjudgmental to encourage free participation by your team members. Most of the time, the true root cause will not be obvious — otherwise, you would have solved the problem already.

Frequently Asked Questions (FAQ) about the 6 Ms

What is the purpose of using the 6 ms .

The 6Ms are used to search for the root causes of a process or product problem. A Fishbone Diagram uses the 6Ms as the main branches of the “Fish.”

What do the 6 Ms stand for?

Although the sequence may vary, the Ms stand for: Machinery, Materials, Methods, Measurement, Manpower, and Mother Nature.

Can I use the 6 Ms for a non-manufacturing problem?

Yes, you can use the approach for root cause analysis in any type of function. But, depending on the application, you may want or need to adjust the meanings of the original Ms.

In a nutshell, what are the 6 Ms?

The 6Ms is a description of the most common process inputs or factors. They are used to help identify the possible root causes of a problem. The Fishbone Diagram is the most common format for the use of the 6 Ms.

The name of the 6M terms may be changed to reflect the specific nature of the process that you are working on. Machinery is often changed to Equipment. Manpower is often changed to People. In non-manufacturing or transactional processes, the 6M terms may be totally discarded and substituted with terms such as Policies, Procedures, Communication, and Training. The name of the term is less important than the process of the root cause analysis.

About the Author

Ken Feldman

Lean Six Sigma Training Certification

- Facebook Instagram Twitter LinkedIn YouTube

- (877) 497-4462

6M Root Cause Analysis in Lean Six Sigma. Everything to Know

April 1st, 2024

Over 20 years of experience applying Six Sigma principles across industries, I have conducted countless root cause analysis utilizing various methodologies.

One such approach that I have leveraged is the 6M Root Cause Analysis technique.

Machines, Materials, Methods, Manpower, Measurement, and Mother Nature provide an intuitive framework for categorizing inputs based on potential factors contributing to process variation.

Key Highlights

- The 6Ms refer to six key inputs that contribute to process variation : Machinery, Manpower, Materials, Methods, Measurement, and Mother Nature

- Categorizing causal factors into the 6Ms provides an intuitive framework for structured brainstorming and analysis

- The approach helps identify root causes by mapping relationships in an Ishikawa/fishbone diagram

- Drilling down under each Ms category uncovers hidden sources of problems

- While utilized in manufacturing, 6Ms adapts well to service, transactional, and administrative processes

- An impact-difficulty matrix can help focus on remediation efforts for most ROI

- For optimal outcomes, verify root causes with data before implementing corrective actions

- Practitioners should refine the 6Ms method based on learnings from completed analyses

This article will explore an overview of the 6M Root Cause Analysis, including its origin and evolution from the foundational principles established by pioneers like Kaoru Ishikawa.

We will explore the mechanics of constructing a 6Ms fishbone diagram to map different causes and drill down to the root sources of quality excursions.

Whether the challenge resides within manufacturing plant floors or informational business processes, the adaptable 6Ms approach facilitates a comprehensive interrogation of inputs to diagnose and remedy issues.

Equipped with this understanding, continuous improvement practitioners can further enrich their causal analysis toolkits to drive transformations.

Introduction to Root Cause Analysis

As an industrial engineer and statistician by training who has led optimization efforts across global corporations, I recognize the major impact that a root cause analysis can have.

Before exploring the versatile 6Ms approach, review foundational concepts and alternative causal analysis techniques.

Types of Causal Analysis

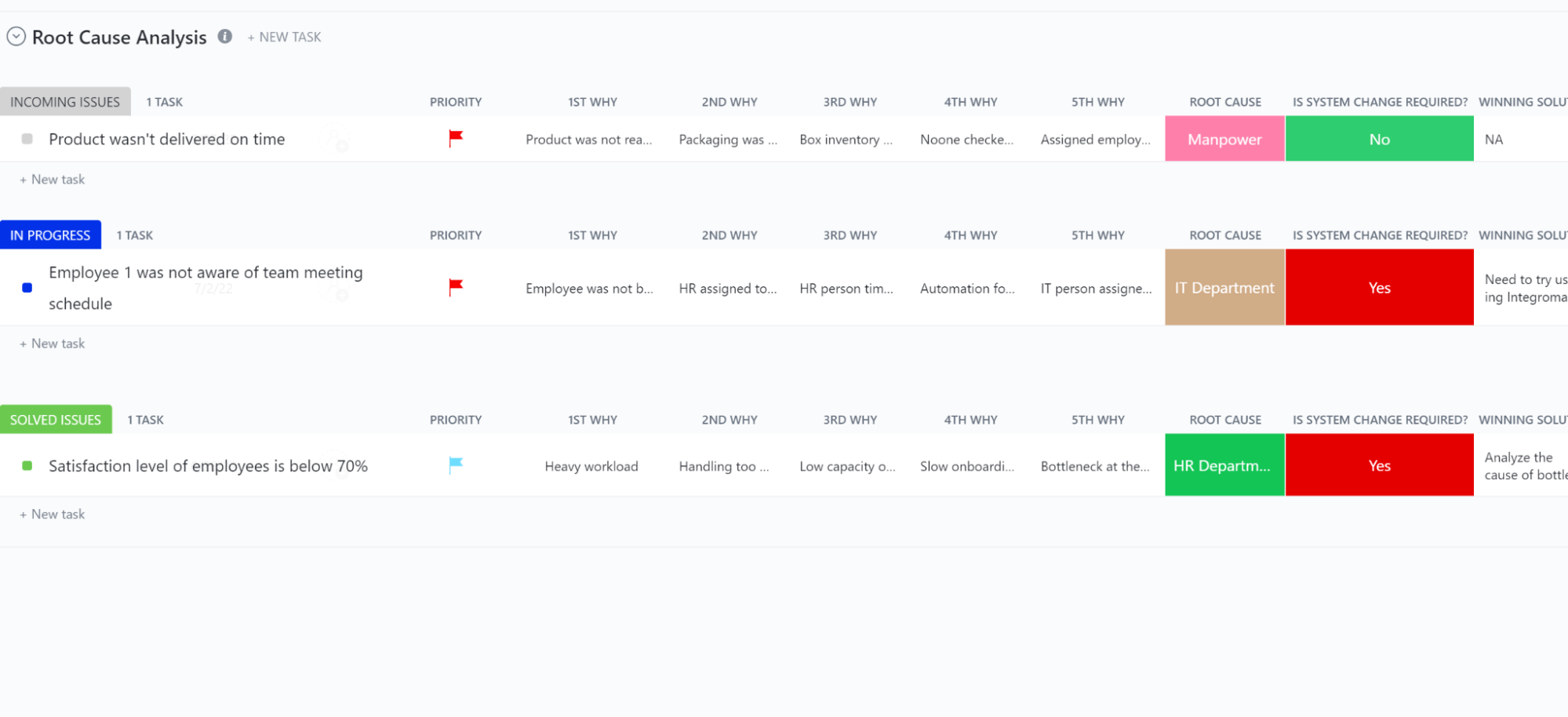

5 whys methodology.

This iterative interrogation method identifies root causes by repeatedly asking “Why?” 5 times .

Each answer forms the basis of the next why question until the source is revealed. While simple in premise, it tests assumptions and deepens understanding.

Pareto Analysis

This statistical approach leverages the Pareto principle that 80% of problems stem from 20% of causes. By quantifying and ranking issues, efforts can concentrate on high-impact vital sources.

Graphical Pareto charts visually depict the disproportionate influence of certain factors.

Benefits of Root Cause Analysis

Whether through 5 Whys, Pareto analysis, or the 6Ms, causal analysis generates breakthrough improvements by fundamentally addressing problems versus merely treating surface symptoms.

This analytical approach directly enhances quality, reliability, and profitability metrics that underpin competitive advantage.

Additionally, the collaborative process of mapping relationships through tools like cause-and-effect diagrams builds shared understanding between functions. This lays the cultural foundation for preventing future issues.

Fishbone Diagram

We will delve deeper into the prevalent Ishikawa or fishbone diagram which offers a structured graphical approach for categorizing the many potential and hidden causes affecting processes. The versatile 6Ms method leverages this visual format to relate causes to the core problem.

Overview of the 6M Root Cause Analysis

While many causal analysis tools exist, the 6Ms approach holds a special place in every Master Black Belt’s toolkit. Its simplicity, adaptability, and completeness uniquely equip the methodology to diagnose the drivers of process variation. Let us explore the anatomy of the 6Ms.

Defining the 6M of Root Cause Analysis

The 6Ms encompass six fundamental inputs that impact manufacturing and service delivery processes. Kaoru Ishikawa standardized these categories while pioneering quality management principles that remain foundational today.

Machinery : Any equipment, production tools, or facility systems involved in operations Manpower : The human resources conducting and managing process execution Materials : Components, consumables, and raw input materials flowing through the process Methods : Specific procedures followed to transform inputs into outputs Measurements : Metrics, inspection readings, instrumentation, and data generated to assess quality Mother Nature : External environmental conditions that can influence process stability

While terminology permutations exist across industries, these six elements comprehensively map the key variables affecting processes.

5 Ms + 1P Variation

A popular variation replaces Mother Nature with “Process” itself as the sixth factor. This firmly widens the scope to include aspects like process flow , plant layout, production sequencing, etc.

The approach also frequently substitutes “People” for “Manpower” and “Equipment” for “Machinery” to reflect modern sensibilities.

Origins and History of the 6M of Root Cause Analysis

The pioneering quality guru Kaoru Ishikawa first outlined the 6Ms in the 1960s while developing cause-and-effect and fishbone diagrams.

As companies adopted these analytical tools, the versatile 6Ms cemented as standard inputs when troubleshooting issues to pinpoint root causes.

Iterations like the 5Ms and 1P demonstrate the flexibility of the approach to adapt to specific needs. Nonetheless, the methodical ethos of interrogating key process contributors persists as the framework’s core.

Using the 6M for Root Cause Analysis

While understanding the backbone of the 6Ms is crucial, its true value manifests while actively diagnosing problems. Let us walk through utilizing the approach for root cause analysis .

Building a Fishbone Diagram

The intuitive visual construct of a fishbone diagram lends itself perfectly to categorizing causes within our 6Ms framework. The problem statement acts as the “head” while each Ms branch composes a “bone” seeking respective sources.

Brainstorming Causes

With the diagram in place, cross-functional teams can brainstorm factors that may contribute to process instability across all Ms branches. The structured format with pre-defined categories stimulates ideas that may otherwise remain hidden without this prompting.

Categorizing Issues

As numerous hypotheses emerge, the team catalogs each cause under the appropriate 6Ms branch. If ambiguity exists, quick voting can determine placement before resuming brainstorming. This organization reveals trends within certain domains.

Drilling Down into Causes

The most fertile territory lies in the deeper roots where few have dug before. Leveraging the 5 Whys approach , the team drills down repeatedly to unravel root causes. When similar suspects arise across multiple branches, pay extra attention to potential smoking guns.

Determining Root Causes

Vet and prioritize all hypothesized causes until primary root cause candidates rise to the forefront for each 6Ms branch. Gather validation data before pursuing any one root issue to prevent resource squandering.

Verifying with Data

While speculative causes should undergo initial vetting earlier, extensive analysis should follow to definitively pinpoint a significant few vital root issues.

Funnel efforts into what the data substantiates rather than assumptions alone. This prevents wasting resources on superficial factors versus high-impact causes requiring remedy.

Applying 6M Root Cause Analysis to Manufacturing

While originally developed for manufacturing environments, the ubiquity and flexibility of the 6Ms framework enable adaptation across functions. Nonetheless, its ability to handle complexity at scale remains a cornerstone application for process improvement practitioners.

Production Line Methods

The structured workflow mandated by production lines introduces risks of variability being introduced and propagated.

The 6Ms analysis can assess if procedures are overly complex, machines are adequately capable of meeting takt time , inspection systems provide actionable data, and environmental conditions meet operating parameters.

Machine Maintenance

As the backbones of manufacturing ops, machines both influence and are influenced by upstream and downstream processes. The 6Ms lens evaluates age, condition, calibration standards, PM rigor , utilization levels, and capability gaps that may manifest as a quality variation.

Raw Material Quality

Input material integrity affects process stability and output quality. The 6Ms will trace inconsistencies back to supplier QA programs, handling, inspection methods, storage conditions, and formulation changes that bleed impacts.

Operator Skills

Frontline personnel directly or indirectly influence production, whether through operation, maintenance, or quality assurance. The 6Ms weigh their proficiencies, knowledge, and experience levels that could contribute to deviations.

Measurement Procedures

Sensors and analytics serve as the eyes and ears providing actionable visibility. The 6Ms evaluate risks of bias, imprecision, uncertainty, latency, and veracity of data streams fueling decision loops.

Environmental Conditions

Cleanrooms to chemical plants mandate stringent ambient parameter compliance. Temperature, humidity, atmosphere, vibration, etc. represent considerations within the 6Ms arena both for facilities and utility systems.

While exhaustive analysis requires blurring the borders between branches, the 6Ms structure accelerates framing the problem space. This omnibus approach prevents overlooking blindspots plaguing narrowly targeted efforts.

Manufacturing staples like TPM and Kaizen enrich remediation insights during and post-6Ms activities.

Applying 6M Root Cause Analysis to Other Domains

While the 6Ms originated from manufacturing environments, its flexibility enables adaptation across other functions lacking direct types of machinery and materials. The technique can diagnose process variability within service operations, administrative workflows, and creative endeavors.

Adapting Methodology

Thoughtful tuning of terminology and perspective broadens the 6Ms beyond production lines. “Equipment” and “People” can substitute “Machinery” and “Manpower” while “Processes” captures workflows. Categorizing contributor types remains central to the refined framework.

Service Delivery Processes

The 6Ms lens can scrutinize variability within service interactions, whether in healthcare, hospitality, or professional services. It weighs procedure consistency, staff skills, data transparency, customer acuity variances, and environmental factors driving execution excellence.

Information Systems

Even virtualized environments interacting with informational systems have relevant analogues for each Ms branch. The methodology evaluates computational capacities, system resources, data integrity, codebases, infrastructure robustness, and external dependencies that could undermine stability.

Marketing Mix

While lackadaisical marketing may not cause catastrophic failures, the 6Ms approach can optimize campaign effectiveness and ROI.

It examines channel selection, offers structuring, metrics visibility, budget allocation, partner coordination, and contextual influences that could enable or hinder resonating with audiences.

The versatility of the 6Ms to not only understand but also actively improve processes indeed spans far beyond the factory floor.

While traditional terminology assumes a manufacturing backdrop, adaptation to match specific environments puts the tool’s utility within reach for knowledge workers.

Keys to Success with 6M Root Cause Analysis

While the 6Ms provide an intuitive checklist for structuring root cause analysis, proper application and mindset tuning unlock its full potential.

Based on extensive practitioner experience, the following keys set the table for 6Ms excellence.

Asking Why Repeatedly

The “ 5 Whys ” philosophy suggesting iterating to root levels applies perfectly to drilling down within the 6Ms branches. Assess each cause through recursive questioning to unravel the deepest underlying contributors.

Updating with New Learnings

Just as processes evolve, so too should refresh the 6Ms framework with additional categories as new process knowledge comes to light through completed analyses.

Ensuring Proper Categorization

As the 6Ms structure seeds the diagram’s construct, judiciously map causes to appropriate branches. If ambiguity exists, democratically vote to maintain momentum.

Considering All Inputs

A common pitfall lies in overlooking certain inputs during the brainstorming.

However, actively hypothesizing potential factors across the wide 6Ms landscape guards against confirmation bias and premature assumptions around root issues.

While formal procedures govern the application, injecting these foundational principles into the 6Ms drives optimal analytical outcomes. Adopting this comprehensive mindset and regularly revisiting assumptions ushers full benefits.

Conclusion & Next Steps

As we bring this exploration of the versatile 6Ms methodology to a close, let us recap key insights and opportunities to enrich future causal analysis efforts.

Summary of the 6M Root Cause Analysis

The elegance of the 6Ms lies in its simplicity and comprehensiveness for categorizing the broad range of process variables that contribute to outcomes.

Whether applied in manufacturing or technical and creative domains, the structured decomposition empowers deeply focused diagnosis.

Importance of Quality Improvement

By methodically considering equipment, talent, materials, procedures, data, and environmental factors influencing processes, the 6Ms approach structures discoveries of significant root causes underlying quality issues.

Targeted remediation of vital inputs then uplifts stability.

Areas for Further Analysis

While powerfully employing the 6Ms as part of a broader analytical toolkit along with data-driven hypothesis validation unlocks maximal benefits. Furthermore, adapting the framing for specific process types can improve relevance.

Continued evolution of the approach will drive ever more incisive insights.

I hope this guide has enriched your understanding of the 6Ms framework thus empowering your continuous improvement initiatives with a sharpened causal analysis toolkit. Please reach out with any other questions as we collectively elevate our practice.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs

SixSigma.us Accreditation & Affiliations

Monthly Management Tips

- Be the first one to receive the latest updates and information from 6Sigma

- Get curated resources from industry-experts

- Gain an edge with complete guides and other exclusive materials

- Become a part of one of the largest Six Sigma community

- Unlock your path to become a Six Sigma professional

" * " indicates required fields

- Guide: Fishbone Diagram

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: October 19, 2023

- Learn Lean Sigma

The Fishbone Diagram, also known by various other names such as Ishikawa Diagram, Cause and Effect Diagram or 6Ms, is a visual tool used in problem-solving and root cause analysis . Originating from the quality management sector, it is used as a systematic approach to identify, explore, and display possible causes of a specific problem.

Table of Contents

What is a fishbone diagram.

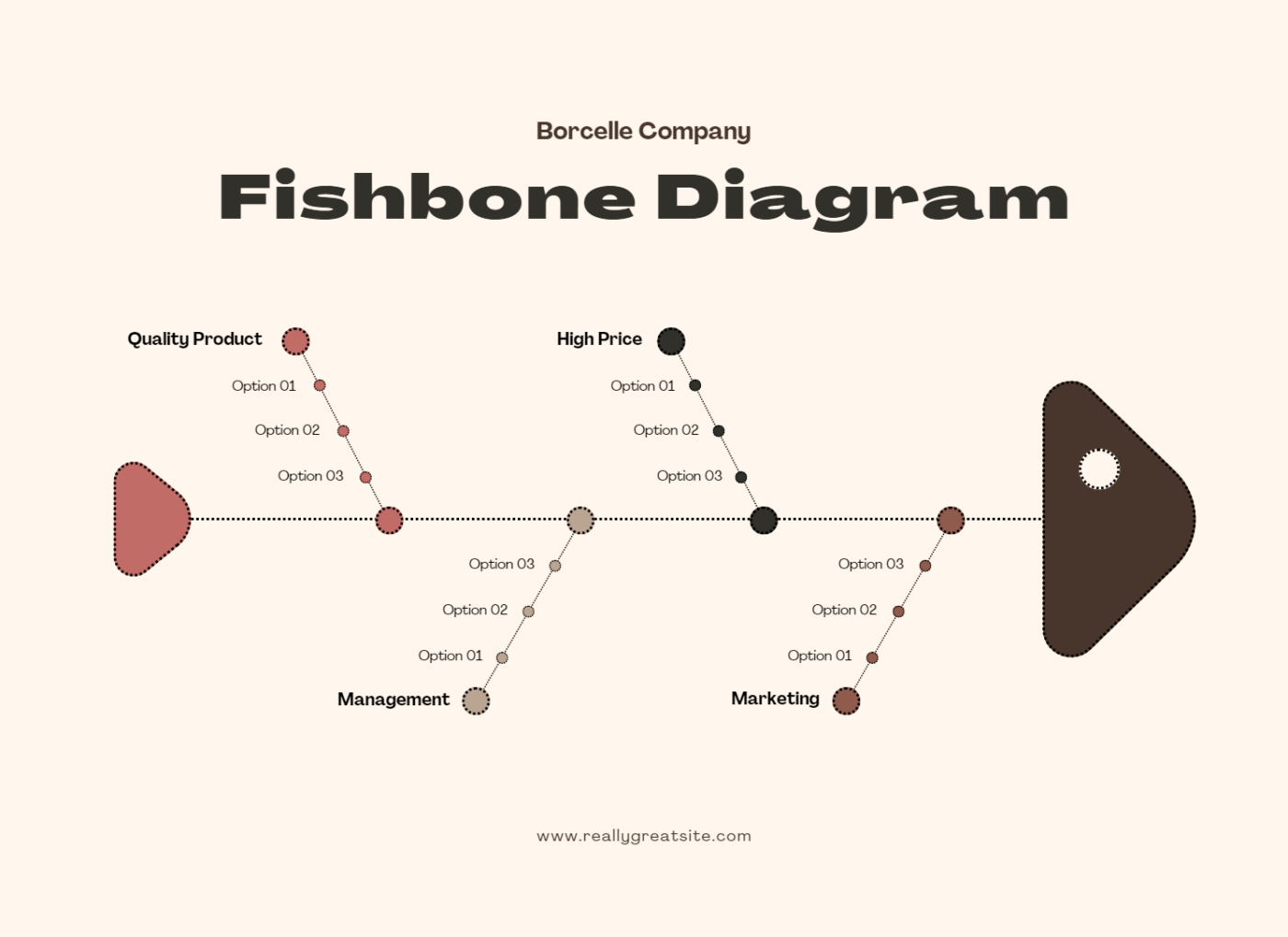

The Fishbone Diagram is a graphical tool used for identifying and organizing possible causes of a specific problem or outcome. The diagram resembles the skeletal structure of a fish, hence its name. At the “head” of the fish is the problem you’re trying to solve, and the “bones” branching off the spine are the multiple potential causes contributing to that problem.

The benefit of a Fishbone Diagram lies in its simplicity. It gives you a structured way to brainstorm and categorize the various factors affecting a specific issue. The diagram can get as detailed as you need it to be, allowing for sub-causes to branch off the main causes, offering even deeper insights.

The Components of a Fishbone Diagram

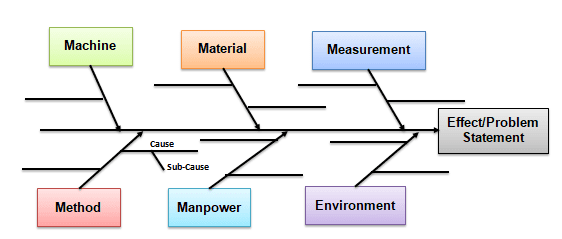

Head : The fish’s head represents the problem or effect you’re analyzing.

Spine : The long, horizontal line connecting to the head serves as the timeline or sequence of the problem.

Bones : These are the categories of potential causes. They branch off the spine, leading towards the head.

Sub-Bones : These are the more specific factors or sub-causes that stem from the main categories.

Why Use a Fishbone Diagram?

The Fishbone Diagram is a flexible tool that can be used for a range of applications. Here’s why it’s so useful:

1. Easy Visualization:

One of the primary advantages of using a Fishbone Diagram is its ability to simplify complex problems. With all potential causes visually represented in one place, it becomes easier to analyze and discuss the issues.

2. Team Collaboration:

The Fishbone Diagram is excellent for brainstorming sessions. It encourages team members to think critically and contributes to a shared understanding of the problem. It’s collaborative by design, allowing for the collective intelligence of the group to shine.

3. Root Cause Analysis:

Identifying symptoms of a problem is one thing; uncovering the root cause is another. The Fishbone Diagram excels at this by forcing you to dig deep into various contributing factors. By isolating these causes, you’re better positioned to find a lasting solution.

By using a Fishbone Diagram, you’re not just addressing a problem with a short-term fix; you’re conducting a thorough investigation to eliminate issues from the root up.

How to Create a Fishbone Diagram: A Detailed Guide

Creating a Fishbone Diagram might seem like a daunting task, but it’s actually a straightforward process. Here, we’ll break down each step in detail to ensure you can construct a Fishbone Diagram that serves its purpose effectively.

Materials You’ll Need:

- A whiteboard or large sheet of paper

- Markers or pens

- Sticky notes (optional)

- A team of people for brainstorming

Step 1: Identify the Problem

The first and most crucial step is to clearly identify the problem you’re trying to solve. This statement should be specific and concise. Write this problem statement at the far right side of your whiteboard or paper, as it will serve as the “head” of your fishbone diagram.

- Use data to define the problem whenever possible.

- Make sure the problem is mutually understood and agreed upon by all team members.

Step 2: Determine the Main Categories

Now, draw a horizontal line from the problem statement towards the left side of the board. This is the “spine” of your fish. Next, you’ll identify the major categories of causes that could be contributing to the problem. These categories will serve as the main “bones” branching off from the spine.

Common categories often include:

- Measurement

- Environment

- The categories can be industry-specific or general, depending on the problem you’re analyzing.

- Aim for 4-6 main categories for better manageability.

Step 3: Brainstorm Causes

Once you’ve determined the main categories, it’s time to brainstorm potential causes for each category. These causes will be the smaller “bones” that branch off from the main bones. If you’re working with a team, this is an excellent time for a brainstorming session.

- Use sticky notes to write down ideas so you can easily move them around.

- Encourage every team member to contribute; sometimes the most unexpected insights come from diverse perspectives.

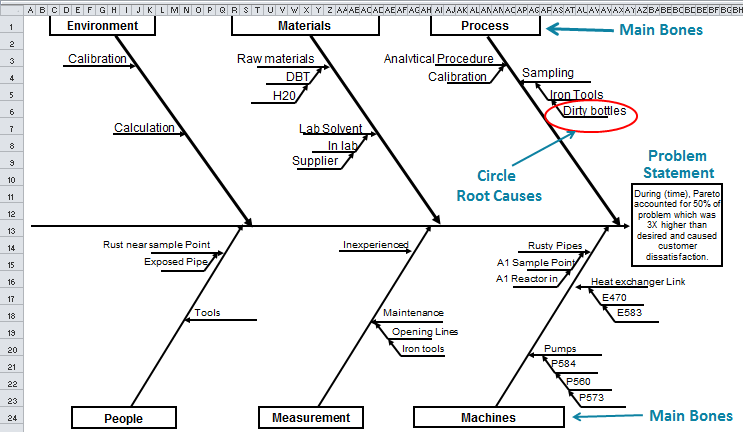

The output of the root cause analysis at this point may look something like the below example. With the lack of preventative maintenance being explored with the 5Whys analysis.

Step 4: Dig Deeper with Sub-Causes

Sometimes, the primary causes can be broken down into smaller, more specific sub-causes. This is where the “ 5 Whys ” technique can be beneficial. For each primary cause, ask “Why?” up to five times to dig deeper into the root of the issue.

- Not all primary causes will need sub-causes; use your discretion.

- Keep the diagram organized to ensure readability.

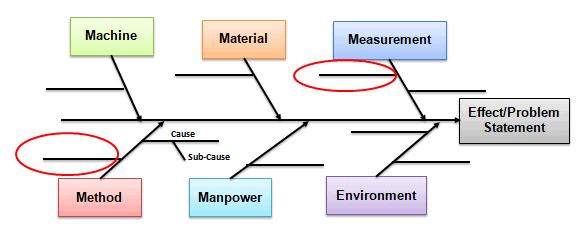

Step 5: Analyze and Take Action

After all the causes and sub-causes have been identified, it’s time to analyze the Fishbone Diagram as a team. Highlight or circle the causes that seem most likely to be contributing to the problem. These are the areas that will need immediate attention and action.

- Use data or evidence to support your conclusions.

- Create an action plan assigning responsibility for each highlighted cause.

And there you have it! You’ve successfully created a Fishbone Diagram that will help you get to the root of your problem.

Examples and Case Studies: Understanding Fishbone Diagrams in Action

Case study: manufacturing unit with quality issues.

Imagine you run a manufacturing unit, and you’ve been receiving complaints about the quality of your products. You decide to use a Fishbone Diagram to get to the root of the issue.

Step 1: Identify the Problem Problem Statement: “High number of defective products in the last quarter.”

Step 2: main categories.

- People : Untrained staff, high employee turnover

- Process : Inconsistent quality checks, outdated SOPs (Standard Operating Procedures)

- Equipment : Aged machinery, lack of maintenance

- Environment : Poor lighting, extreme temperature fluctuations

Step 4: Dig Deeper (5 Whys)

- Untrained Staff : Why? No formal training program.

- Aged Machinery : Why? No budget allocated for equipment upgrades.

After analyzing the Fishbone Diagram, you realize that untrained staff and aged machinery are your primary culprits. Your next steps could involve investing in staff training programs and allocating budget for machinery upgrades.

By following these steps, you can develop targeted strategies to improve product quality significantly.

Common Mistakes and Tips: How to Make the Most of Your Fishbone Diagram

1. overlooking minor causes.

While it’s easy to focus on the most glaring issues, minor causes can accumulate and have a significant impact.

Tip : Don’t disregard a cause just because it seems minor. Sometimes, fixing smaller issues can lead to big improvements.

2. Ignoring Data

It’s tempting to rely solely on brainstorming and intuition, but data should be your guiding star.

Tip : Use metrics and KPIs to support or refute the causes you’ve identified. This adds credibility to your findings and helps you prioritize effectively.

3. Stopping at Symptoms

Identifying symptoms is just the first step; your ultimate goal should be to uncover the root causes.

Tip : Use techniques like the “5 Whys” to dig deeper into each cause and ensure you’re addressing the root of the issue, not just its manifestations.

Fishbone Diagrams are a fantastic asset in the toolbox of anyone interested in continuous improvement. Whether you’re a seasoned professional or just getting started, this simple yet powerful tool can help you dissect complex problems and develop targeted solutions.

They encourage you to look beyond the obvious and delve into the intricacies that contribute to each problem. So go ahead, grab that pen and paper (or a whiteboard, if you’re feeling fancy), and start your journey towards effective problem-solving.

- Ilie, G. and Ciocoiu, C.N., 2010. Application of fishbone diagram to determine the risk of an event with multiple causes. Management research and practice , 2 (1), pp.1-20.

- Coccia, M., 2018. The Fishbone diagram to identify, systematize and analyze the sources of general purpose Technologies. Journal of Social and Administrative Sciences , 4 (4), pp.291-303.

Q: What is the origin of the Fishbone Diagram?

A: The Fishbone Diagram was originally developed by Dr. Kaoru Ishikawa, a Japanese quality control statistician, in the 1960s. It’s also sometimes referred to as the Ishikawa Diagram in his honor.

Q: Can Fishbone Diagrams be used for non-manufacturing problems?

A: Absolutely! While Fishbone Diagrams are popular in manufacturing and quality management, their application is not limited to these areas. They can be used in healthcare, software development, event planning, and even for personal problem-solving.

Q: How many main categories should my Fishbone Diagram have?

A: The number of main categories can vary depending on the complexity of the problem. However, it’s generally advisable to have between 4-6 main categories for easier analysis and readability.

Q: Can I use software to create a Fishbone Diagram?

A: Yes, there are several software tools available for creating Fishbone Diagrams, such as Microsoft Visio, Lucidchart, and various other project management software options. However, a simple pen and paper or a whiteboard can be just as effective for smaller teams or simpler problems.

Q: How do I know which causes to prioritize after creating a Fishbone Diagram?

A: After creating your Fishbone Diagram, you should analyze it with your team to identify the most likely root causes of the problem. Using data to support your conclusions can be very helpful. You may also employ techniques like the Pareto Analysis to prioritize causes based on their impact.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

Was this helpful.

Get started

- Project management

- CRM and Sales

- Work management

- Product development life cycle

- Comparisons

- Construction management

- monday.com updates

Fishbone diagram template for fast root cause analysis

Cause and effect are critical factors for project teams or anyone working to improve a process, as it lets you make informed decisions when changes arise throughout a process. A cause and effect diagram — or fishbone diagram — helps teams or individuals brainstorm root causes so they’re better positioned to create more viable solutions or improvements.

At first glance, these diagrams look a bit complex, but the premise behind them is fairly simple. We’ll walk you through problem-solving with these diagrams, and you’ll also find a Fishbone Diagram Template you can use right away for brainstorming sessions on monday.com.

Get the template

What is a fishbone diagram template?

A fishbone diagram — also sometimes called an Ishikawa diagram, after its inventor — is a brainstorming tool designed to force teams to look at the cause and effect relationship between inputs and outputs. When one of these diagrams is completed during a meeting or individual brainstorming session, the results usually look somewhat like the skeleton of a fish.

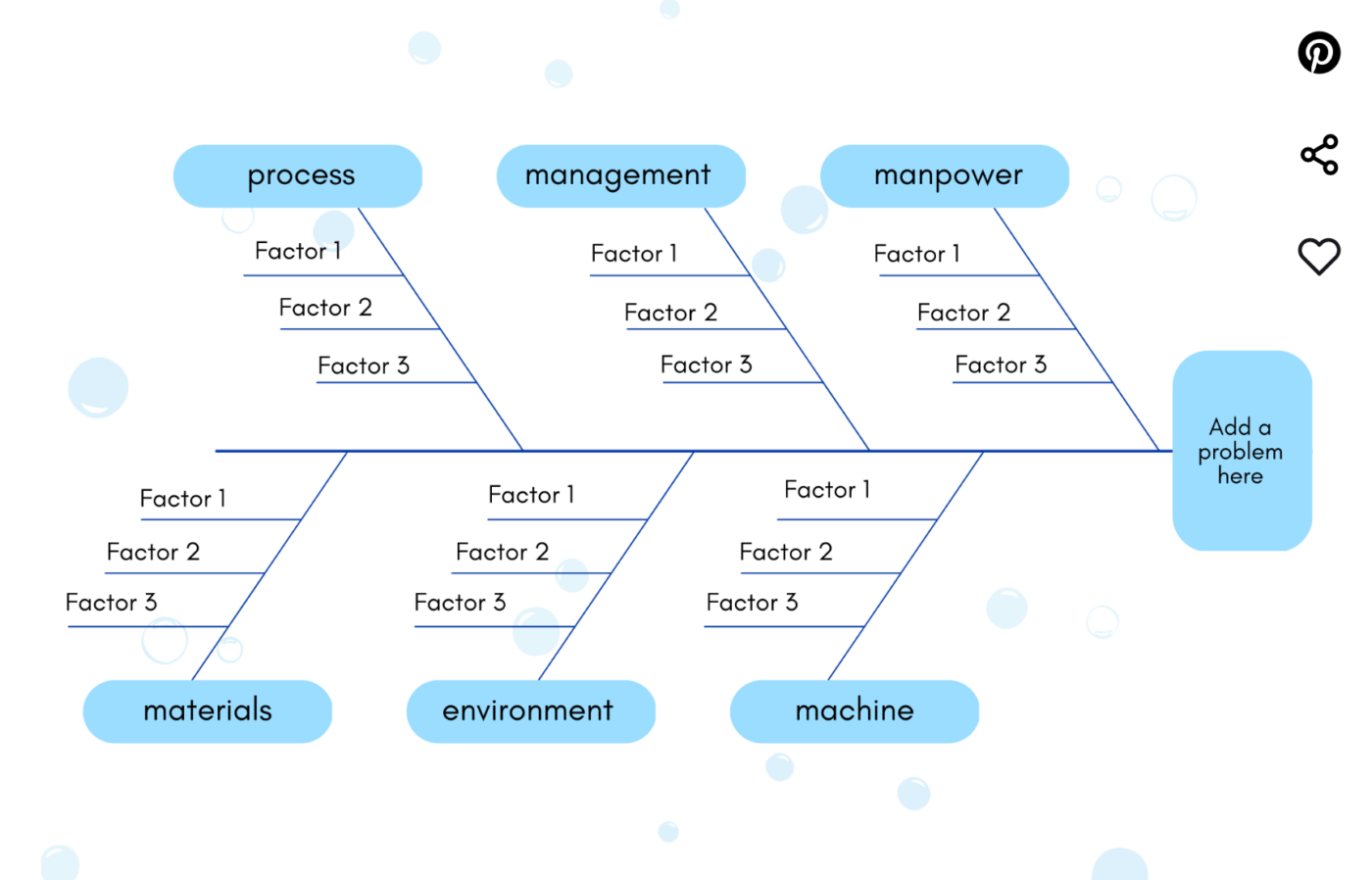

A fishbone diagram template is a blank diagram with space for recording a problem statement or final outcome as well as categories or affinities and the inputs relevant to each.

The components of a fishbone diagram template include:

- The fish head: On the right-hand side of the diagram, you record the problem or final outcome you’re dealing with in a shape that represents the fish head.

- The fish spine: A single line extends to the left, tying the problem or final output to the rest of the diagram.

- Fish bones: Lines extend off the central line for each category or affinity.

- Input spaces: Additional lines or spaces extend off the category or affinity lines, providing space so you can record individual inputs.

Why use a fishbone diagram template?

The main advantage of a fishbone diagram template is that it provides individuals and teams with some structure for brainstorming that can be used again and again. When using a digital template — like the one on monday.com — it’s even easier to update the diagram as you go and keeps things moving swiftly even when challenges are identified

Digital templates also let the team see updates in real time as they discuss root causes, driving more effective analysis. Teams can better categorize inputs and provide a clear record to circle back to for review based on factors such as:

- Overall impact on the final outcome

- How easy they might be to change

- Whether they are required or not

Who should use a fishbone diagram?

These diagrams are also versatile — you can use them in software development, banking, manufacturing, and even home renovation or DIY projects. This is because you can expand the fishbone diagram’s core structure to fit many use cases, which we will learn about next.

Examples of fishbone diagram templates

The main difference across fishbone diagram templates is which affinities or categories you start with and how many you include. You can use a simple fishbone template for a customized approach or start with a 4S, an 8P, or a 6M fishbone. The latter three options are preset with categories that are most commonly used in specific industries.

Simple fishbone

Since the simple fishbone template comes without preset affinities or categories, it works for almost any purpose. Say you’re a supply chain leader and your company’s product sales have slowed. You can pinpoint the issue(s) using a fishbone diagram for a transparent view of pricing, quality, advertising, and sales.

Fishbone diagrams let teams create categories that are most important or relevant for their field or project. For example, dev teams working on a software deployment work in categories that differ from clinical teams working to reduce patient readmission rates.

4S fishbone

The 4S approach is a favorite for service industry teams that want to create a fishbone diagram to solve challenges by pinpointing potential causes. It’s also helpful in identifying a manufacturing plant’s internal processes. The 4S fishbone template starts with the following categories:

- Surroundings: Inputs related to locations and environments

- Suppliers: Inputs related to vendors and anyone else that supplies resources, including materials and labor

- Skills: Inputs related to skills that employees, leadership, vendors, and other parties bring to the table

- Systems: Inputs related to software, equipment, and processes

8P fishbone

The 8P approach includes more categories and is common in service industries like retail, hospitality, and food. You can use the template in a variety of other areas, such as administrative functions and manufacturing processes, especially with a few modifications. Service industries use the 8P fishbone diagram to analyze:

- Price: Inputs related to cost or pricing

- People: Inputs related to personnel

- Place/Plant: Inputs related to work locations and environments

- Procedures: Inputs related to prescribed procedures or habits for getting tasks done

- Promotion: Inputs related to sales and marketing

- Processes: Inputs related to what is supposed to happen and how

- Product: Inputs related directly to the product

- Policies: Inputs related to governing policies for processes or procedures

6M fishbone

The 6M fishbone includes preset categories that work well for manufacturing teams or for anyone working to make a product. A 6M fishbone template typically includes categories for:

- Measurements: Inputs related to inspections or measurements

- Machines: Inputs related to equipment, tools, and facilities

- Man: Inputs related to labor and skills

- Mother Nature: Inputs related to environmental factors

- Methods: Inputs related to processes

- Materials: Inputs related to raw goods and other required components

If choosing the right categories is the first step in success with cause-and-effect diagrams, the second step is ensuring you record the diagram so the team can refer to it and work from it in the future. monday.com lets you create fishbone diagrams from templates and capture the information gathered in working sessions for use on boards or in other templates.

Start using monday.com’s fishbone diagram template

monday.com Work OS provides teams with the functionality required to execute seamless, productive brainstorming sessions. That’s true whether you’re working on a continuous improvement project or simply addressing challenges discovered in day-to-day processes.

You can create dynamic, visual process flows to capture current and desired workflow as teams brainstorm future states. Or you might rely on color-coded Gantt charts to keep teams on the same page and timeline with processes or project efforts.

We make it easy for teams of all types and sizes to leverage tried-and-true project management and productivity tools to drive efficiencies, maximize work on great ideas, and keep communication clear and open. Start with our Fishbone Diagram Template to experience some of these benefits if you’re working to define root causes. With it you can:

- Map out the cause and effects of issues or challenges to best identify solutions and improvements

- Benefit from both a flexible board and our visual whiteboard for brainstorming

- Add actionable items that you can assign due dates and owners

Then check out some of our other project management templates. Whether you need an easy way to record project goals or conduct more specific root cause analyses, templates are great tools to start with.

Related monday.com templates

You can find hundreds of project management templates in our Template Center . Consider starting with one of the options below to streamline communication and project oversight as you work with others toward success:

- Single project template: Customize a monday.com board to capture and track information to help you and your team execute a single project. Start with our Single Project Template and then move on to kanban views, Gantt charts, and other features to make project work easier.

- IT root cause analysis template: Dev and technical teams can solve problems and drill down to root causes with our IT Root Cause Analysis Template .

FAQs about fishbone diagrams

How many types of fishbone diagrams are there.

Technically, a fishbone is a specific type of diagram. You can create variations by changing the categories or affinities you start with. Some fishbone diagrams only have four categories while others have six or eight. You can add as many categories as you need, though each one you add increases the complexity of your analysis.

Is there a fishbone diagram in Word?

Microsoft Word doesn’t have a built-in fishbone diagram. You can make one in Word using the “insert shapes” and “draw” functions. You might also find templates online people created for use in Word, but it won’t be as intuitive as a Work OS.

Is there a fishbone diagram in Excel?

Excel also doesn’t have a built-in fishbone diagram, but you can make one using shapes and other drawing features in spreadsheets. You might also find downloadable Excel fishbone diagrams other people created and are willing to share.

Turn brainstorming sessions into action plans with monday.com

Getting your team together in the conference room or on a Zoom session is a great start to problem-solving. Your second step should be capturing the discussion and ideas generated by brainstorming to drive future decisions and action.

Our Fishbone Diagram Template is ideal for quickly recording important factors from discussions about cause and effect. You can customize many of our other templates and boards to record and work with all types of information.

Send this article to someone who’d like it.

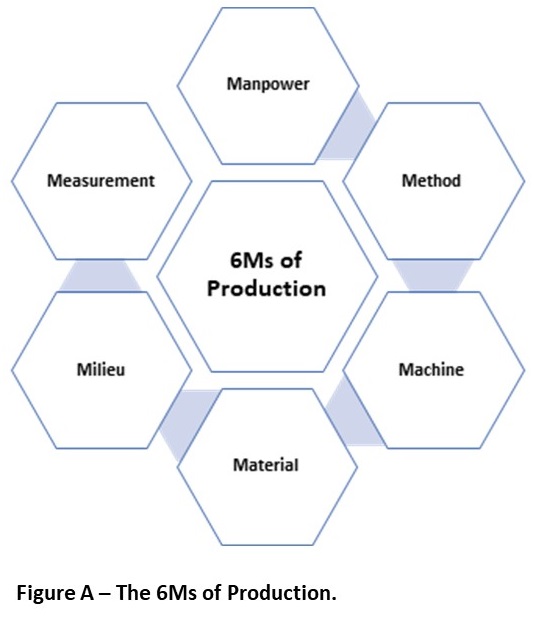

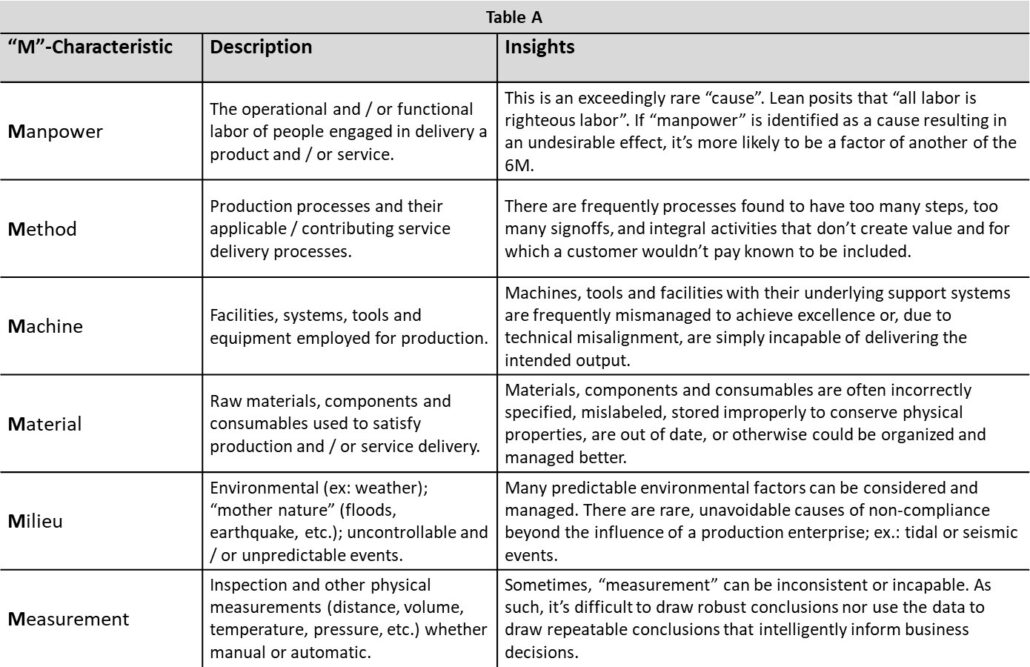

6Ms of Production (man, machine, material, method, mother nature and measurement)

The 6Ms of production – Manpower, Method, Machine, Material, Milieu and Measurement – is a mnemonic representing the characteristic dimensions [1] to consider when brainstorming during “cause and effect” problem-solving sessions. Capture and bin the issues (causes) under the 6M categories. Once documented, place the causes according to category on a cause and effect diagram [2] . Develop improvement plans starting with the most significant issues first. When we think in terms of categories, it helps us separate and then rank the specific causes for various effects and problems.

Question: We could use your help – seriously. We (Kaufman Global) get a ton of traffic on this web page – about 5x more traffic on this page than any other. I would appreciate some insight – can you tell me if you searched for a specific term that took you to this page or, if you searched for something else and you somehow landed on this page? Thank you so much for any insight. I can be emailed at [email protected] – Jerry

The 6Ms of Production

One important tool in this methodology is an Impact Difficulty Matrix. This technique determines the potential impact of each solution and the difficulty of implementing the solution. By ranking solutions in this way, the easiest to do with the least amount of effort, rise to the top of the list for implementation.

6M Characteristics, Description and Insights:

[1] In an information economy with knowledge workers, this also comprehends the notion of discrete and / or supporting “service” delivery.

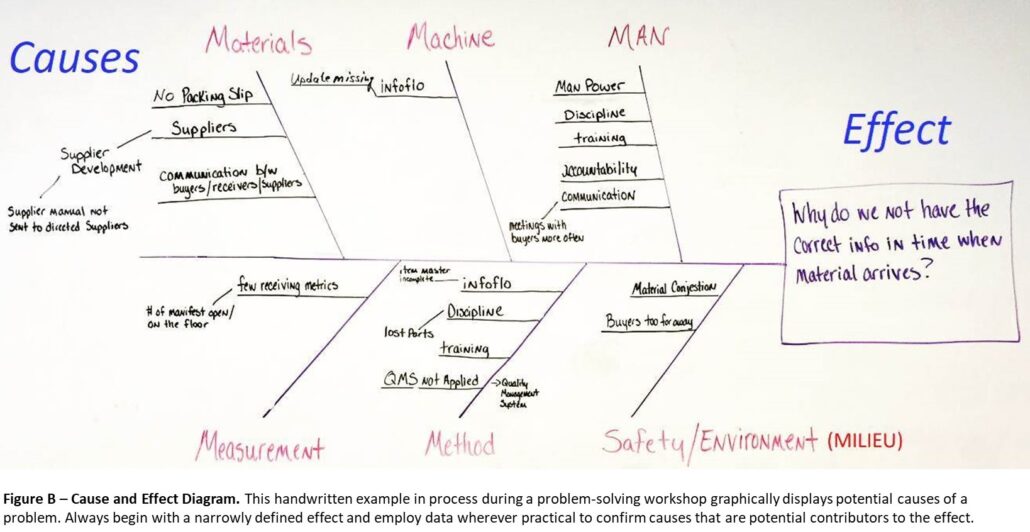

[2] Understanding how these factors impact the process and the establishment of standards are key steps in strengthening production processes. The 6M factors are used to construct cause-and-effect diagrams. Also known as a Fishbone Diagram due to its appearance (or, an Ishikawa Diagram as named after its developer, Kaoru Ishikawa). Example in Figure B below.

Home PowerPoint Templates Models 6M of Production PowerPoint Template

6M of Production PowerPoint Template

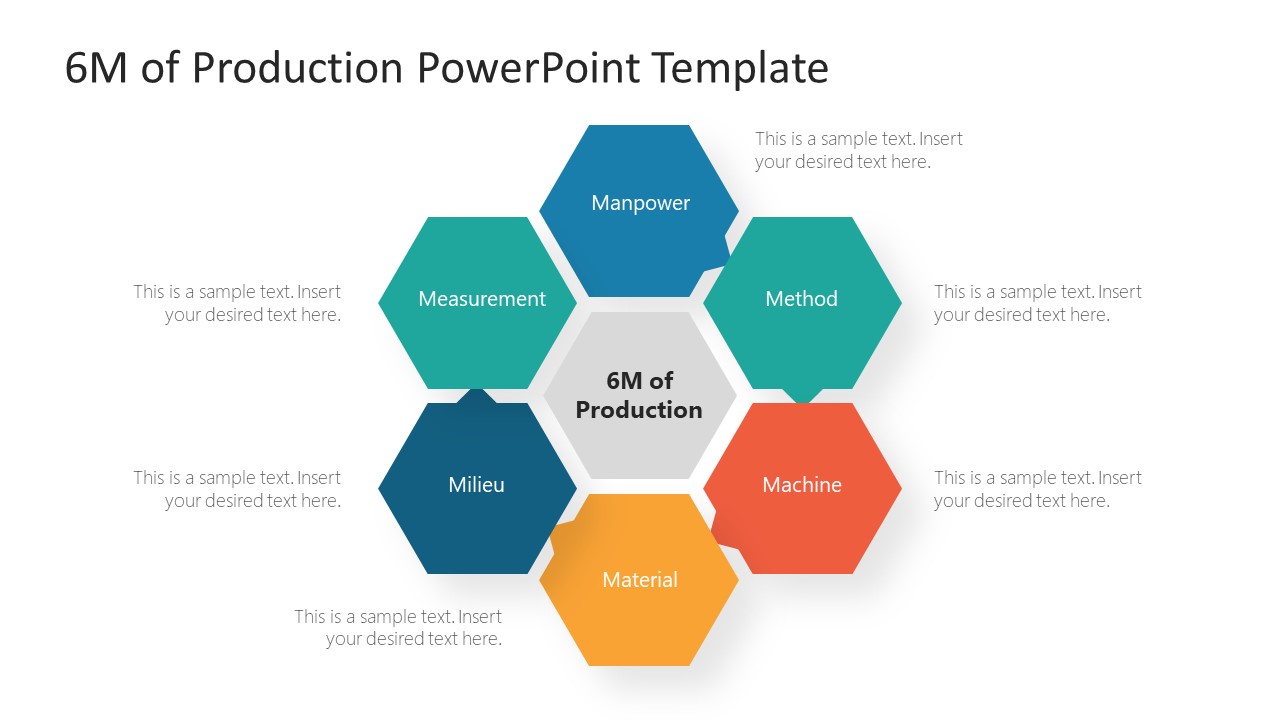

The 6M of Production PowerPoint Template presents brainstorming techniques in three easy-to-understand diagrams. 6M refers to six components; Manpower, Method, Machine, Material, Milieu, and Measurement. It is generally devised for finding the root-cause of problems in manufacturing industry. The PowerPoint slides of 6M of production display 6 steps process cycle diagram, tabular chart, and fishbone diagram. The fishbone diagram template is a popular root-cause analysis method where head of fish is the problem statement. Whereas, the bones represent categories of causes i.e. 6Ms. Each slide contains text placeholders to add discussion points for problem-solving sessions. These slides will help display relevant information in engaging presentation styles.

The 6M are basically characteristic dimensions to look at when trying to solve a problem. 6Ms are the contributing elements for finding root-cause of discrepancy in the process. For example, the Manpower ranks personnel’s experience, sense of responsibility, and discipline. Method or methodology affects the outcome due to different parameters in a workflow. The state of Machineries such as age or overuse can produce varying results. Sometimes, quality of Material can impact the overall production. The results may also vary when Measuring method or gauge is different. Lastly, Milieu, environmental factors like temperature can also influence production.

6Ms helps separate causes into categories and then rank these causes for various effects. This technique is also used in other business divisions such as resources, quality, management, and marketing. The 6M of Production PowerPoint Template could be used effectively to demonstrate complex problems and approach to resolve those problems.

You must be logged in to download this file.

Favorite Add to Collection

Details (3 slides)

Supported Versions:

Subscribe today and get immediate access to download our PowerPoint templates.

Related PowerPoint Templates

6-Circle Venn Diagram Template for PowerPoint

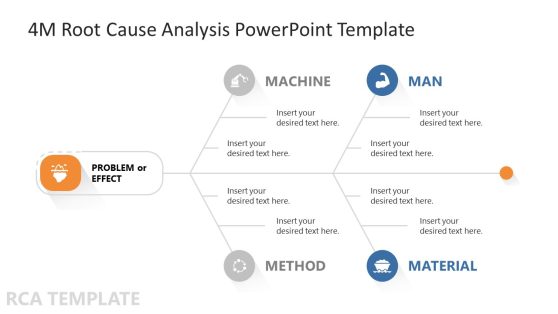

4M Root Cause Analysis PowerPoint Template

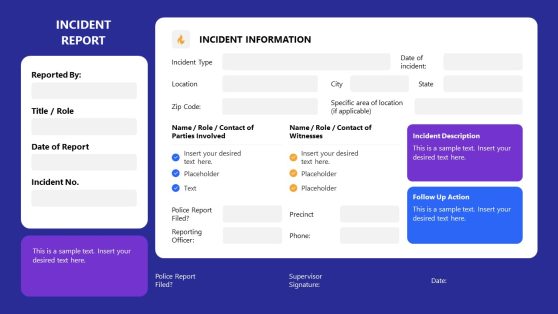

Incident Report PowerPoint Template

Lab Report PowerPoint Template

Understanding the 6Ms of Process Control

An Ishikawa or fishbone diagram is a tool commonly used to brainstorm potential causes as part of a problem-solving process. At the head of the fish is the problem, while each bone represents a category of contributing factors.

These categories are based on the 6Ms of process control, also called the 6Ms of production or problem-solving.

Here we break down the 6Ms, plus a technique we use at The Luminous Group for using this tool to go beyond root cause analysis to foster process excellence.

Download your free Ultimate Guide to Layered Process Audits for a powerful strategy to reduce defects, complaints and quality costs

What Are the 6Ms?

The 6Ms of process control are a framework for categorizing process inputs that could be causes of a quality problem. When variation exists in these process inputs, quality problems are more likely to occur. When the 6Ms of a process are stable as intended, quality issues can be prevented. The 6Ms are:

- Man (People)

- Mother Nature (Environment)

- Measurement

1. Man (People)

This category refers to variation in human behavior, whether it’s variation in worker behavior over time or different techniques used among multiple people. For example, two people using the same work method may perform a process differently if one is tired, works too fast, gets distracted or had different training.

Machine refers to variation in equipment operation. For instance, perhaps due to normal wear and tear on a machine, it no longer drills a hole in a part where it should be.

Variation in methods themselves shouldn’t typically occur once you have the procedure documented. Variation in how operators perform methods would be categorized under People.

In some cases, methods can vary when different work instructions are used to create similar parts for different clients. This situation would warrant considering whether operators are using the right method or were provided with sufficient training to be competent.

4. Mother Nature (Environment)

Environmental conditions can affect equipment performance as well as the stability of raw materials, making it an important source of variation to consider when evaluating quality problems. For example, high temperatures in the work area can cause distortion in some parts. Polymer pellets are also a good example, where high or low humidity can impact the drying process.

5. Material

While manufacturers expect raw materials to conform to requirements, supplier-related quality issues are common and should be evaluated during the problem-solving process. Material-related variation can happen, for example, if a product is labeled incorrectly, or if the incorrect parts or material were brought to the assembly line, or if the supplier has a known history of quality issues.

6. Measurement

Variation in measurements includes how measurements are taken as well as the accuracy of measurement equipment. For instance, if a gauge isn’t in good condition, it might not provide the right value. This makes it difficult to spot non-conforming parts or even make conforming parts appear as suspect or scrap.

The 7th M: Management

One final M that manufacturers are starting to incorporate into their problem-solving processes is management. In some instances, management can unintentionally cause unwanted variation, or cause a problem via omitting a needed action.

For example, let’s say during a 5 Whys analysis that you find out a machine wasn’t maintained properly because you’ve lost two operators and management hasn’t hired replacements. In this case, management not meeting its responsibility is the contributing factor that needs to be addressed.

Using the 6Ms to Define What Needs to Go Right

While the 6Ms are typically used in the context of root cause analysis, manufacturers can also use them to define what needs to be done right. Consider what would happen, for instance, if elements from each of the 6Ms are slightly off, but not out of conformance. Maybe the machine is a little worn and not advancing fully, or the operator is slightly off in how they load the part. All it takes is slightly more variation or a stack-up of variation factors to cause a quality problem.

The 6Ms can help you think about how you can drive all of that variation to zero, helping improve metrics such as defective parts per million (DPPM) and first-pass yield (FPY). Proactive companies take time to research and define these conditions, rather than just reacting to problems.

Running what-if scenarios can be helpful here, such as asking what happens if an operator retires. What elements must you check to make sure the new employee is doing the right things to prevent variation? Another powerful what-if is to ask what has to be done or checked after a power brown-out or power disruption. It’s better to have a contingency plan in your back pocket than to scramble after the customer files a complaint.

The 6Ms are a useful tool for exploring the cause of a problem, as well as a proactive planning tool for defining the conditions required for process excellence. Know that the 6Ms aren’t always cut and dried, so you don’t want to get hung up on which category a cause goes into. The important thing is to have a conversation about it with the people closest to the job, so you can create controls to prevent it and build layered process audit questions to verify your most risky 6M factors.

Take the next step in your LPA journey with the The Ultimate Guide to LPAs

Related articles

Six Sigma Study Guide

Study notes and guides for Six Sigma certification tests

6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P)

Posted by Ted Hessing

In the Analyze phase of DMAIC , we want to identify the root cause of the defects that are causing variation in our process. Sometimes the culprits are easy to identify. We use the 6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P) to find the possible root cause of the process variation or problems. More often, we have to hypothesize what is causing the variation and then test that hypothesis to see if our hunch was right. But how do you come up with a hypothesis for what is causing variation?

In Six Sigma, we describe process variation in terms of 6M’s (aka 5 M’s and 1 P). These are six elements that contribute to variation in a process. Those six elements – 5 Ms and on P (or 6Ms) influence variation in all processes – manufacturing or not.

The 5Ms and one P is a concept that is a quality management and problem-solving methodology, particularly in the manufacturing industry. They represent six potential sources of problems or causes for variations in a process. The 5Ms stand for:

Ishikawa states the 6 Ms (also known as the 5 Ms and 1 P) as Man, Machine, Material, Method, Measurement, and Mother Nature.

- Mother Nature’s “Environmental”

- (Man) People

- Measurement

Let’s Takes A Look at 6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P) Attributes

6 ms in manufacturing example.

- Following an assembly line is much different than a manufacturing floor that does not.

- Empowering any single employee to stop the entire production line if he finds a defect.

- If the supplier measures in English units and the manufacturer measures in metrics, issues could arise.

- The age and robustness of the machine may impact the process.

- Some materials are harder to work with than others.

- Ambient humidity may cause more breakdowns in machines than normal.

6 Ms in Management

- If one team is developing software following a Waterfall approach while a second is using an Agile practice and a third is using Kanban, each method is different.

- Offices in the north are more lenient to snow days than those in the south.

- People untrained in 6 Sigma tend to focus on the ‘Man’ portion of the 6Ms when looking at a process.

- A manager who is unenlightened in six sigma is most likely going to focus on Man. Unenlightened managers tend to think of the process performance as being influenced more by the person component than by the other five components of the six Ms of the machine, material, method, measurement, or mother nature. (Don’t ask whom, ask why.)

- It’s difficult to evaluate teams evenly if each team leader rewards their teams for different behaviors.

- Software development productivity may be different if developers have slower machines or worse tools to use.

- Employees can only build a product as good as the raw materials they get.

How to develop a Cause and Effect Diagram using 5Ms and 1P

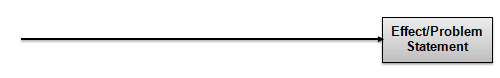

The Cause and effect diagram is a structured graphical diagram listing all possible causes and their relationship with the main effect or problem. The diagram’s basic input is the brainstorming that pushes to identify all the possible causes rather than just more noticeable ones.

Following are the steps to draw a fishbone diagram:

1: Identify the problem:

- Identify and clearly write down the effect or a problem that needs to be analyzed

- Then create an operational definition of a problem to ensure all the stakeholders will understand it

2: Determine Effect or Problem:

- Draw a horizontal line. This is a spine

- At the end of the spine, towards the right, draw a box and determine the description of an effect

3: Identify major causes contributing to the effect or a problem

- Establish main causes and write down a few main causes above the horizontal line and a few below the horizontal line. Make sure they are placed on the tail of the same arrows.

- Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation.

- Man/People: Anyone involved with the process.

- Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations, and laws.

- Machines: Any equipment, computers, tools, etc., required to accomplish the job.

- Materials: Raw materials, parts, pens, paper, etc., used to produce the final product.

- Measurements: Data generated from the process that is used to evaluate its quality.

- Environment: The conditions, such as location, time, temperature, and culture, in which the process operates.

4: Identify sub causes

- Identify as many sub-causes that are relevant to the main causes

- For instance, if the sub-cause applies in multiple places, list it under each main category.

5: Analyze the diagram

- At this time, the fishbone diagram shows all the possible causes of an effect.

- Identify causes that are not impacting the effect and also identify causes that need further investigation.

- Further, perform a 5Why analysis of the identified causes (also called noises) to arrive actual root cause.

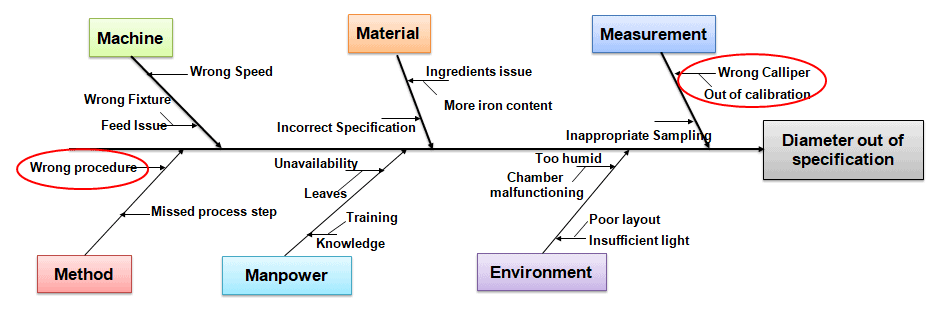

Six Sigma 5M and 1P Example

By and large, Fishbone diagrams are used to identify the root causes of a problem in the “Analyze” phase of Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, and Control). Example: XYZ is a valve manufacturing unit receiving persistent customer complaints about the valve diameter. The plant’s General Manager asked QA and Production team to conduct a root cause analysis. So, the team performed Brainstorming and drew the Cause and Effect diagram to identify all the possible causes.

The team identified that the wrong caliper and wrong procedures were the probable causes. Further, the team has to perform a 5 Why analysis to identify the root cause.

6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P) Template Download

Benefits of 6m’s in six sigma (six ms or 5ms and one p or 5m1p).

- The framework helps in troubleshooting, root cause analysis, and implementing effective corrective actions to improve quality, productivity, and overall performance.

- Further, it graphically displays all the possible causes related to a problem to discover the root causes.

- Helps the team to focus on the problem and brainstorm until the elimination of the root cause.

- Easy to implement in any case.

6M Insights

- When you have a bell-shaped curve , none of the 5 Ms or one P are unduly influencing the process.

- Six elements contribute to variation in a process. Those six elements – 5 Ms and on P (or 6Ms) influence variation in all processes – manufacturing or not.

- You could also use the 6M approach as a spine on each of the fishbone diagrams and then ask the 5 whys to narrow down the potential root cause.

5 m’s and one p

6m’s in six sigma (six ms or 5ms and one p or 5m1p) practice questions, unlock additional members-only content, thank you for being a member.

I originally created SixSigmaStudyGuide.com to help me prepare for my own Black belt exams. Overtime I've grown the site to help tens of thousands of Six Sigma belt candidates prepare for their Green Belt & Black Belt exams. Go here to learn how to pass your Six Sigma exam the 1st time through!

Comments (6)

Variation by Method -Drilling can be done in single/multiheades machines or in a modern CNC machine. Based on your product cycle you can choose a method wherein which variation & cost to be considered Variation by men performing the operation will come thro. his skill/experience level he got with

Thanks for the addition! Much appreciated.

Hi I’ve heard it before; 5 M Mother nature use for outdoor workshop and indoor you can Control Envioment.

Thanks, Larry. That’s a neat variation I haven’t heard of before.

Thank you for the concise 6M analysis method summary. On another note I see that you used Boy Scout merit badges as visual inserts haha.

Hah! You noticed!! Glad it was helpful, Kenneth!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Insert/edit link

Enter the destination URL

Or link to existing content

Filter by Keywords

10 Fishbone Diagram Templates in Word, Excel, & ClickUp

Praburam Srinivasan

Growth Marketing Manager

February 13, 2024

Brainstorming sessions can be fun. Still, when a major problem occurs, they easily turn into intense and nerve-racking thinking marathons. 🏃

That’s where fishbone diagrams come in. Although simple, they are valuable tools for unraveling complex issues, identifying their causes, and coming up with viable solutions .

You don’t even have to make one yourself. You can use one of many pre-existing fishbone diagram templates and get started in minutes. We’ll share some of our favorites, so stay tuned!

What Are Fishbone Diagram Templates?

What makes a good fishbone diagram template , 1. clickup fishbone diagram template, 2. clickup cause & effect template, 3. clickup root cause analysis template, 4. microsoft word fishbone diagram template by templatelab, 5. cause & effect fishbone diagram template by creately, 6. microsoft word fishbone graphic organizer template by template.net, 7. fishbone whiteboard diagram template by template.net, 8. excel ishikawa fishbone diagram template by qimacros, 9. excel simple fishbone diagram template by someka, 10. fishbone diagram template by canva, top 10 fishbone diagram templates—an overview, benefits of using a fishbone diagram template.