The Easy Guide to Solving Problems with Six Sigma DMAIC Method

The most commonly used methodology in Six Sigma is the DMAIC process. Many use it to solve problems and identify and fix errors in business and manufacturing processes.

In this post, we will look at how to use the DMAIC process to solve problems. You will also find useful and editable templates that you can use right away when implementing DMAIC problem-solving in your organization.

- What are 5 the Steps of Six Sigma

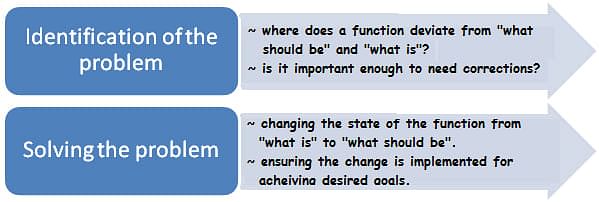

DMAIC Process and Problem-Solving

Common mistakes to avoid when using six sigma dmaic methodology, how to use the dmaic methodology for problem solving in project management, what are the 5 steps of six sigma.

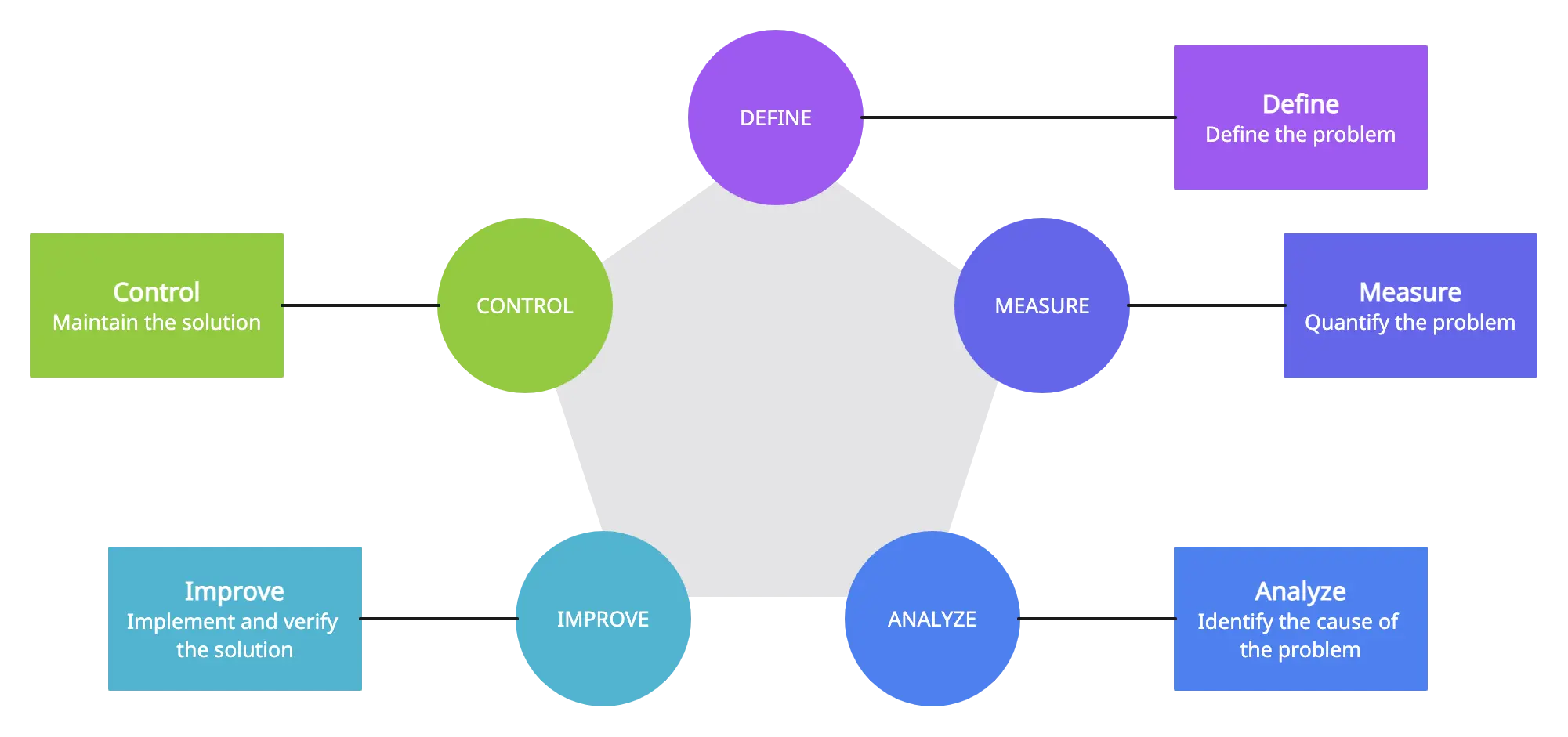

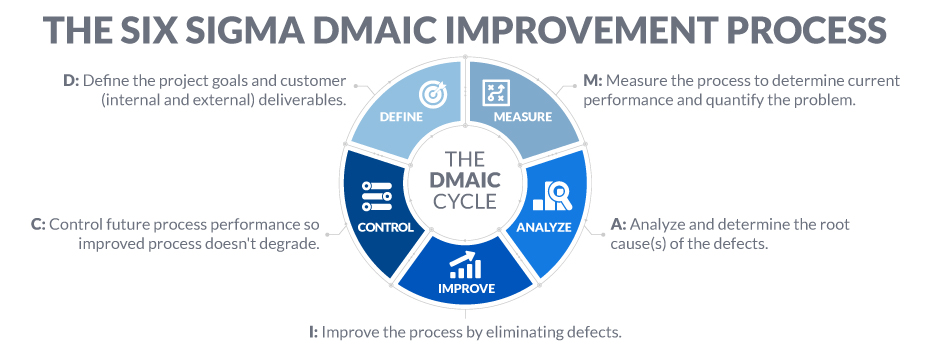

DMAIC is one of the core methodologies used within the Six Sigma framework. It is a data-driven method used to systematically improve the process. The approach aims to increase the quality of a product or service by focusing on optimizing the process that produces the output. This way DMAIC seeks to provide permanent solutions when it comes to process improvement.

It provides a structured problem-solving framework to identify, analyze, and improve existing processes. DMAIC guides practitioners through a series of steps to identify the root causes of process issues, implement solutions, and sustain the improvements over time.

Following we have listed down the 5 phases of the DMAIC process along with the steps you need to take when using it to solve problems. Different tools for each phase is provided with editable templates.

Step 1: Define the Problem

So there’s a problem that affects your customer or your company processes. In this first step of the DMAIC problem solving method , you need to focus on what the problem is and how it has affected you as a company.

There are a few steps you need to follow in this phase.

• Create a problem statement which should include a definition of the problem in quantifiable terms and the severity of the problem.

• Make sure necessary resources such as a team leader and competent team members, and funds etc. are available at hand.

• Develop a goal statement based on your problem statement. It should be a measurable and time-bound target to achieve.

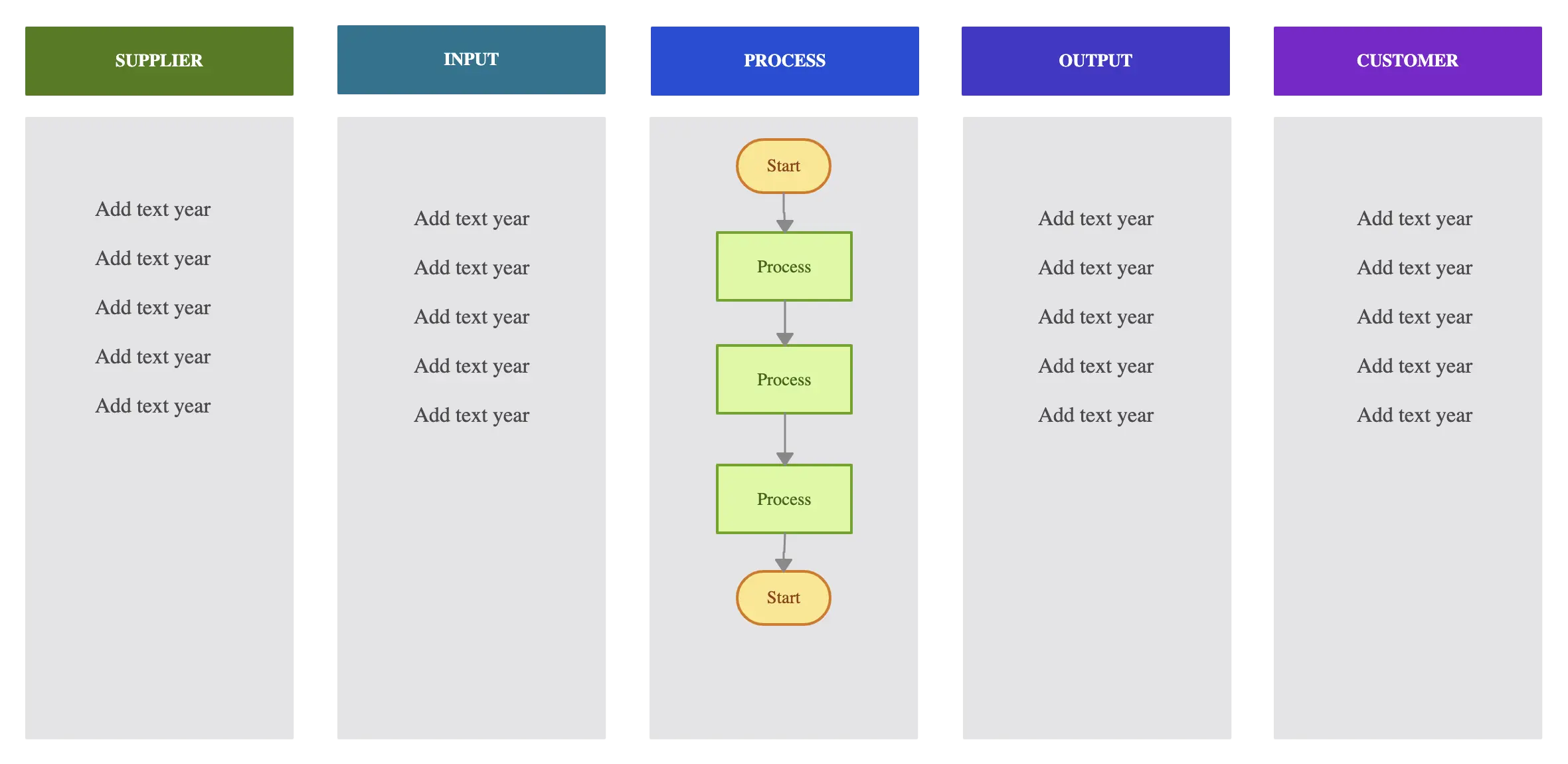

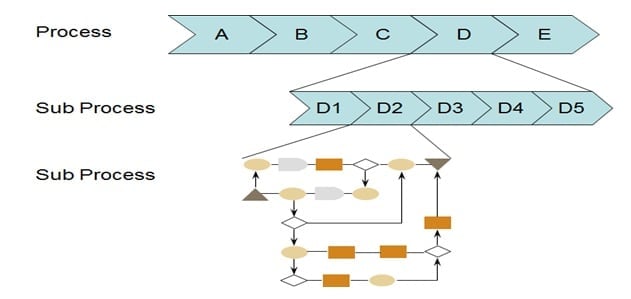

• Create a SIPOC diagram which will provide the team with a high-level overview of the process (along with its inputs, outputs, suppliers, and customers) that is being analyzed. You can also use a value stream map to do the same job.

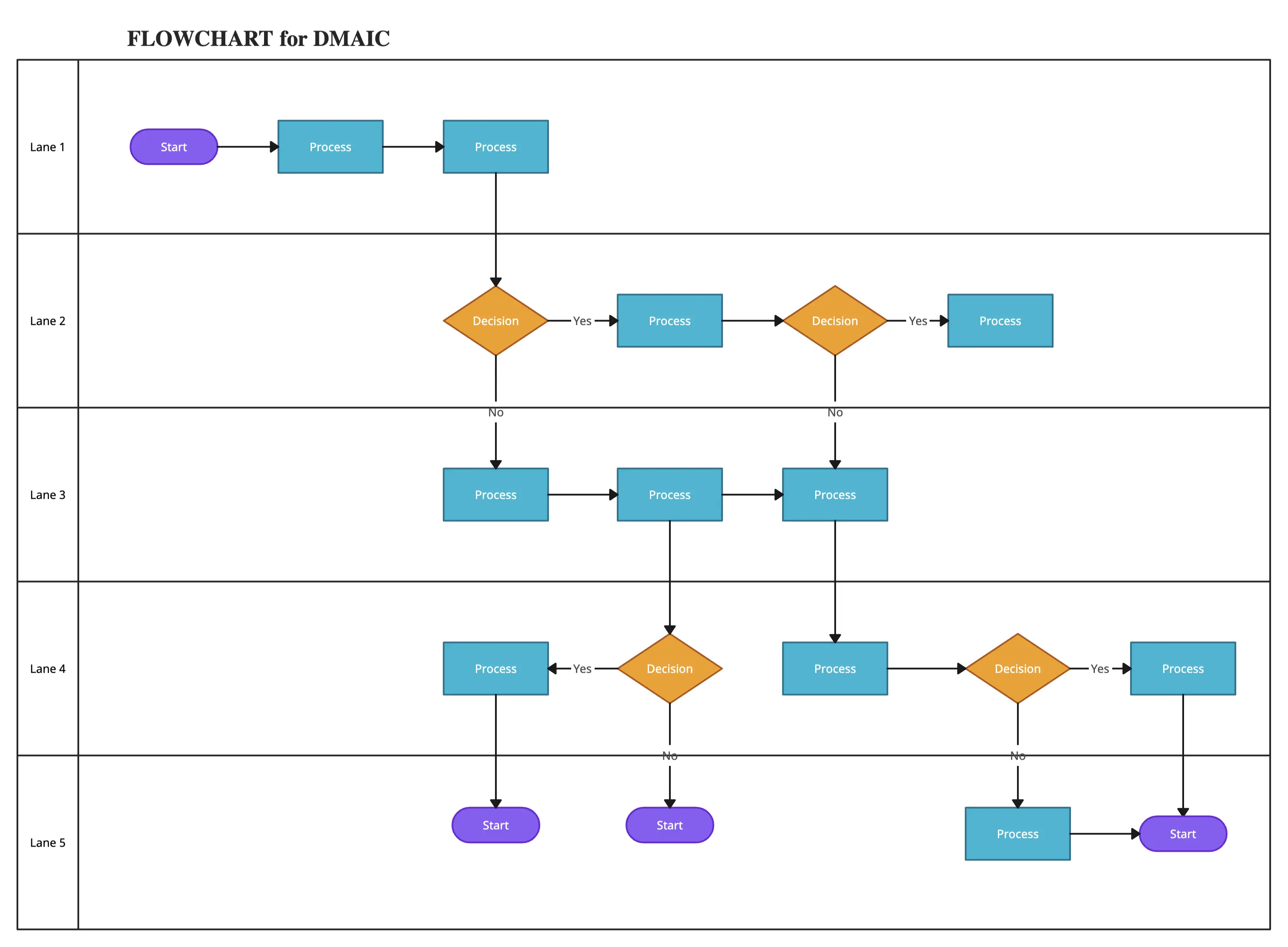

• Try to understand the process in more in-depth detail by creating a process map that outlines all process steps. Involve the process owners when identifying the process steps and developing the map. You can add swimlanes to represent different departments and actors responsible.

Step 2: Measure the Problem

In this step, you should measure the extent of the problem. To do so you need to examine the process in its current state to see how it performs. The detailed process map you created in the ‘Define’ phase can help you with this.

The baseline measurements you will need to look into in this phase, are process duration, the number of defects, costs and other relevant metrics.

These baseline measurements will be used as the standards against which the team will measure their success in the ‘Improve’ phase.

Step 3: Analyze the Problem

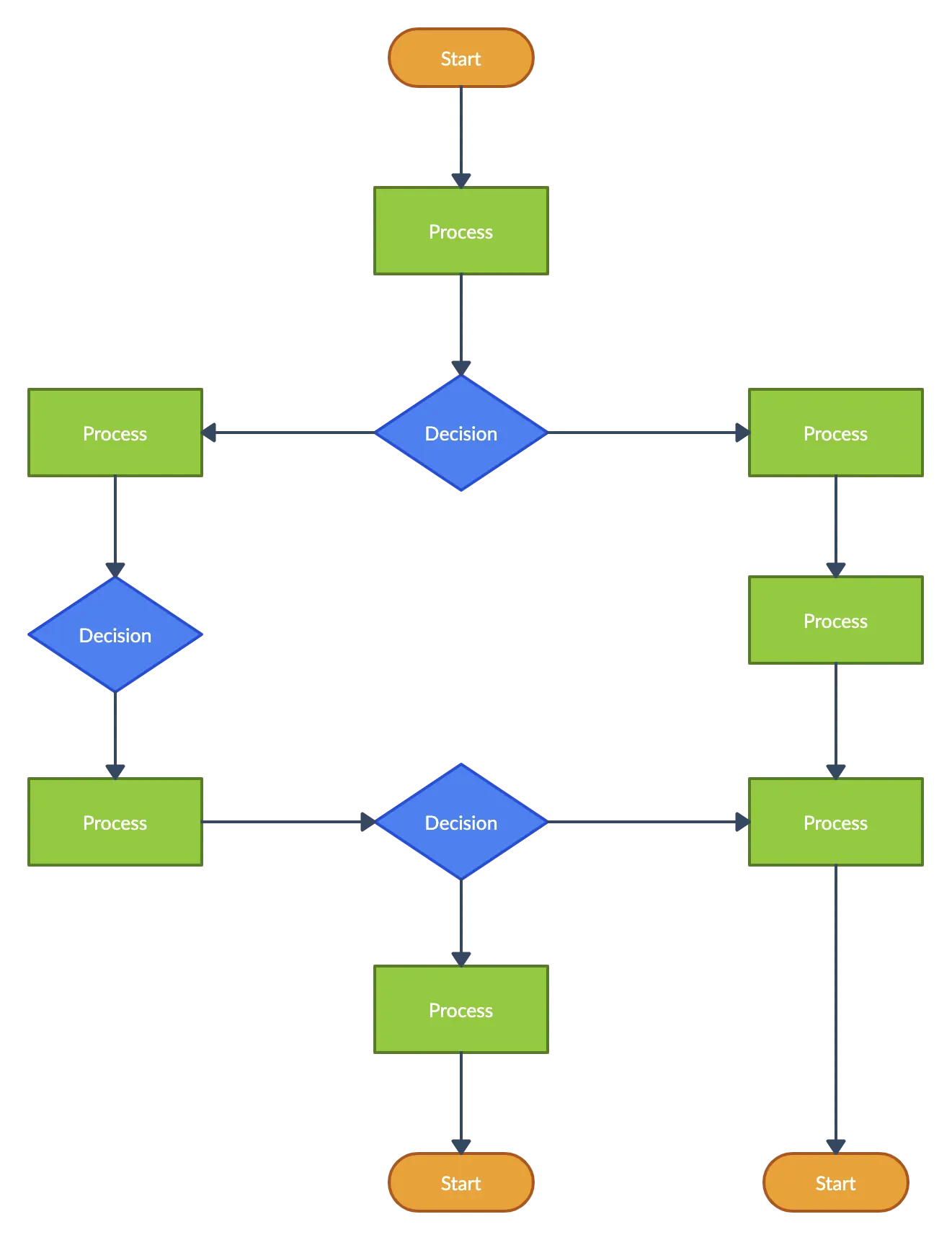

The analyze phase of the DMAIC process is about identifying the root cause that is causing the problem.

• Referring to the process maps and value stream maps you have created, further, analyze the process to identify the problem areas.

• Visualize the data you have collected (both in the ‘Measure’ phase and the analyze phase) to identify signs of problems in the processes.

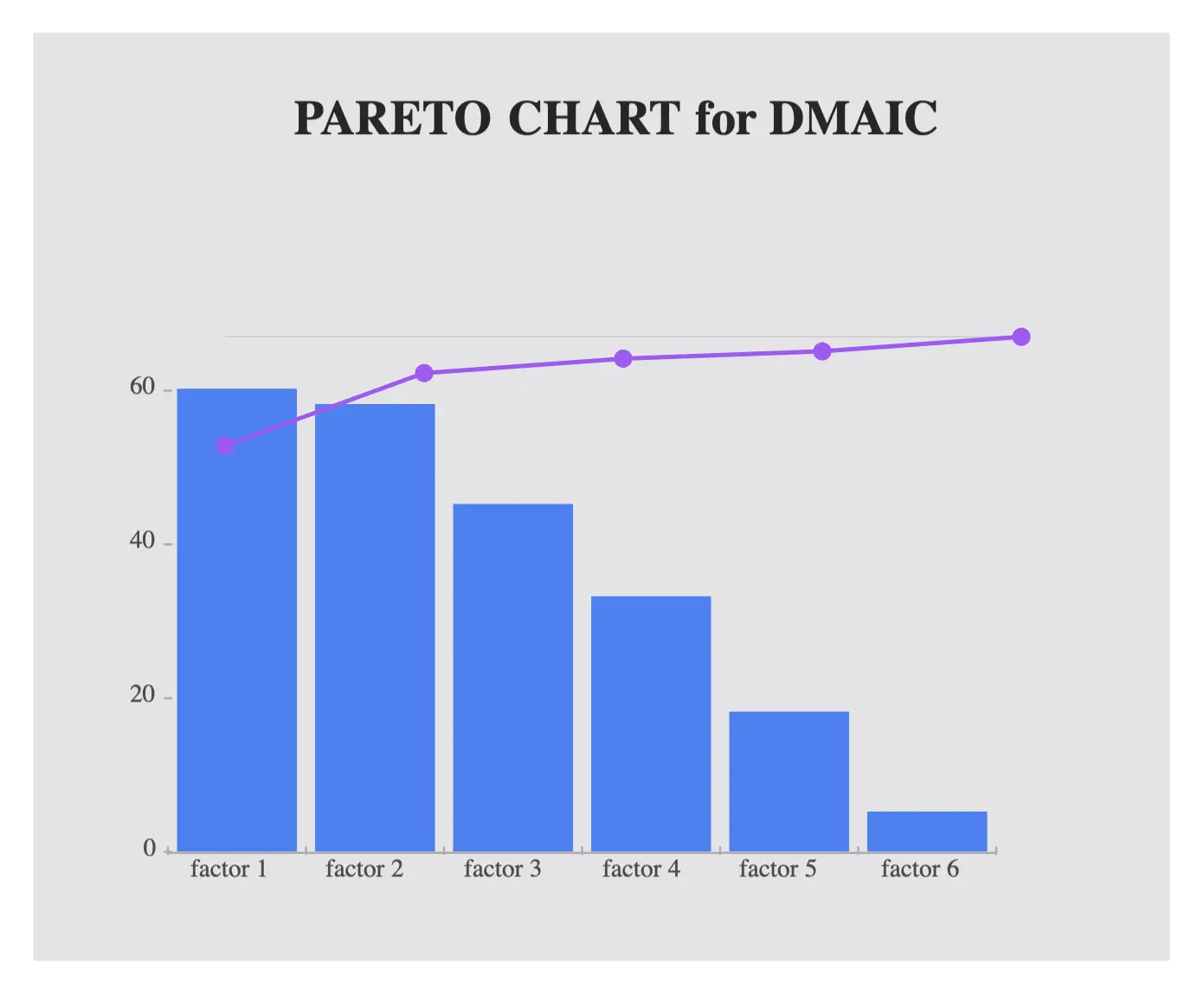

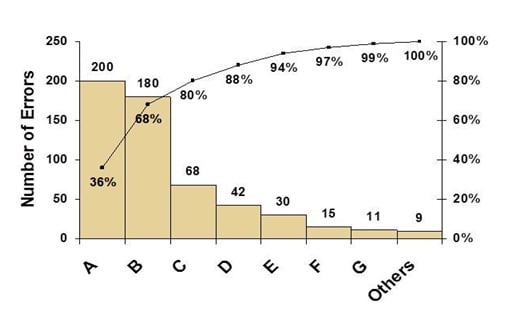

• Use Pareto charts, histograms, run charts etc. to represent numerical data. Study them with team leaders and process owners to identify patterns.

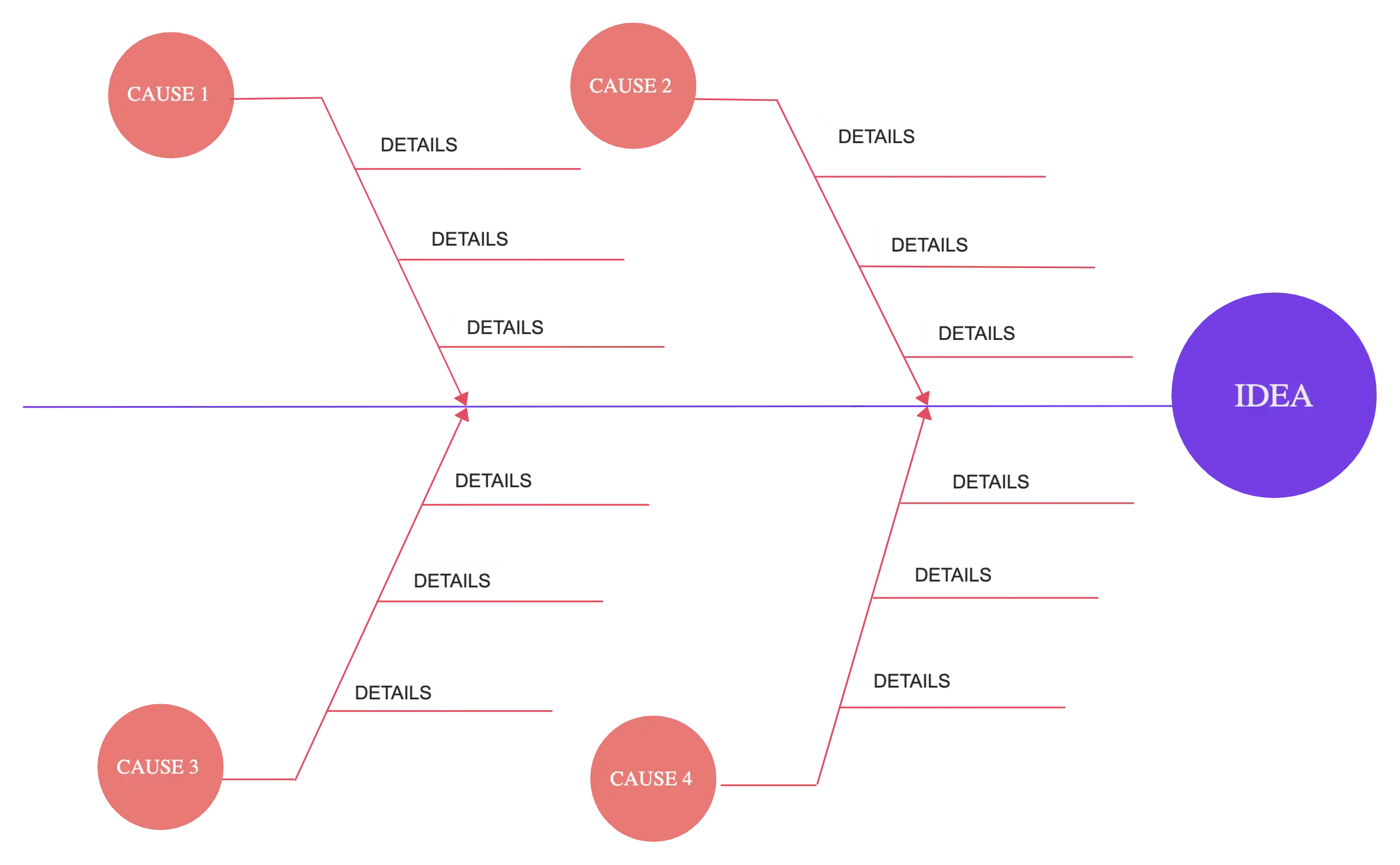

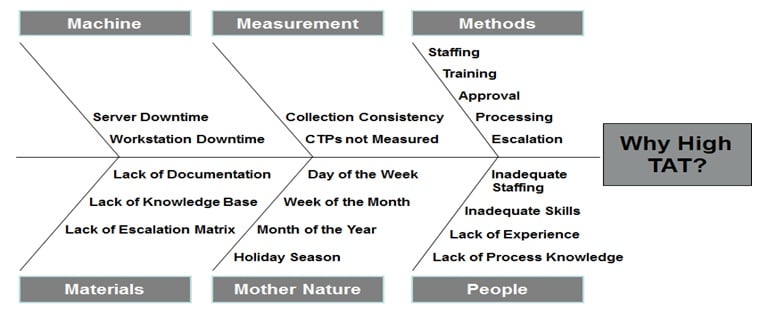

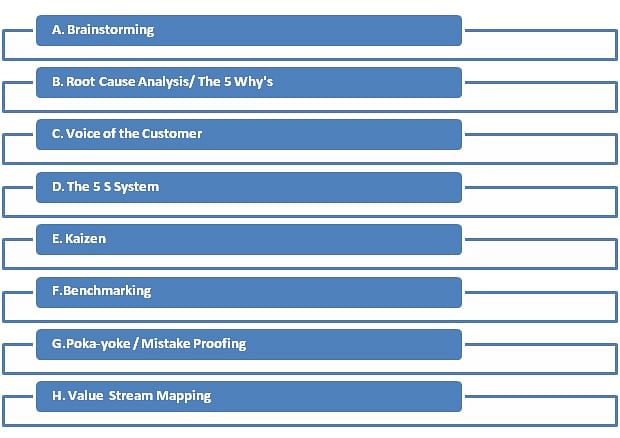

• With the results of your process analysis and your data analysis, start brainstorming the root causes of the problem. Use a cause and effect diagram/ fishbone diagram to capture the knowledge of the process participants during the session.

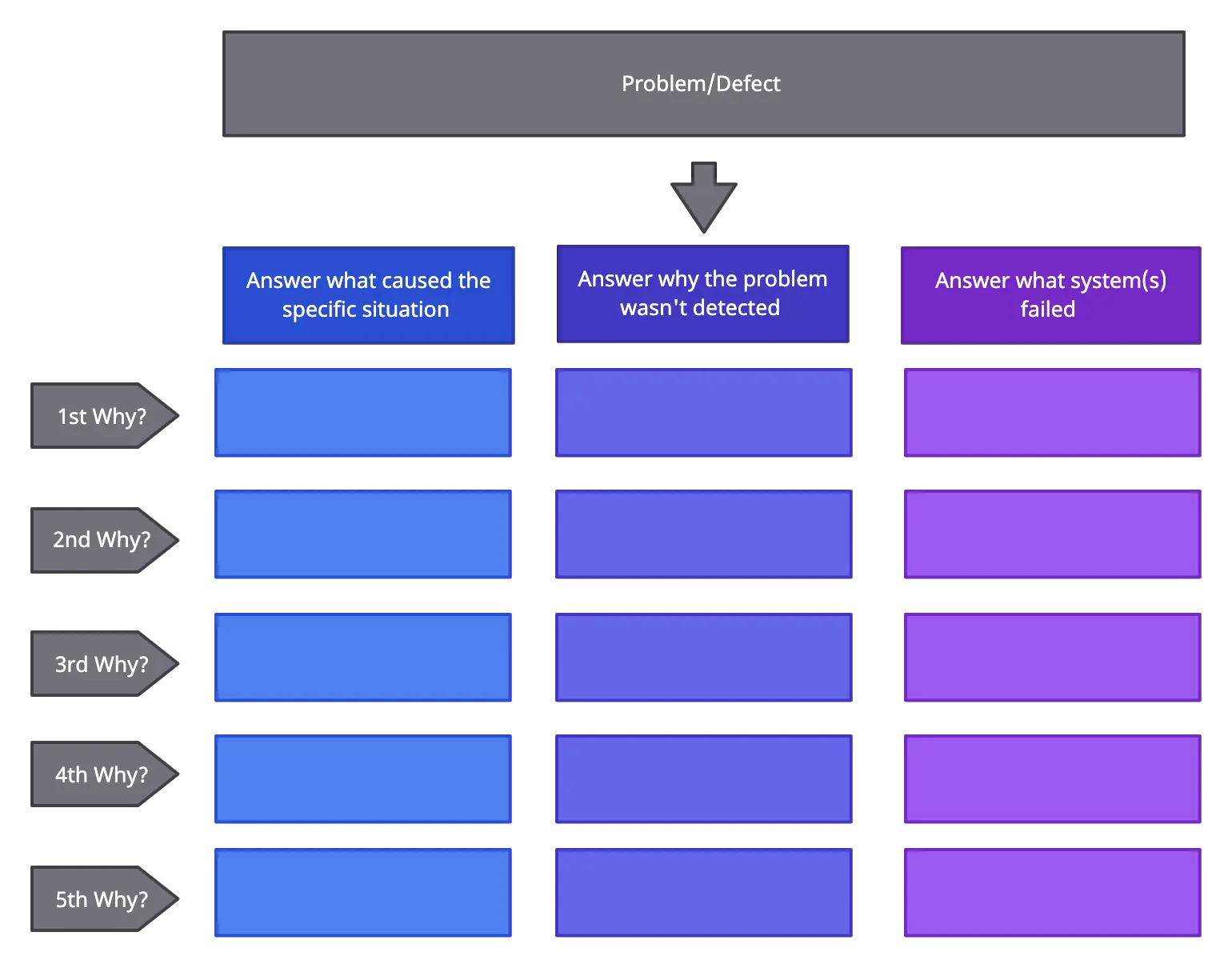

• Using a 5 whys diagram, narrow down your findings to the last few causes of the problem in your process.

Step 4: Improve (Solve the Problem)

In this phase, the focus is on mitigating the root cause identified and brainstorming and implementing solutions. The team will also collect data to measure their improvement against the data collected during the ‘Measure’ phase.

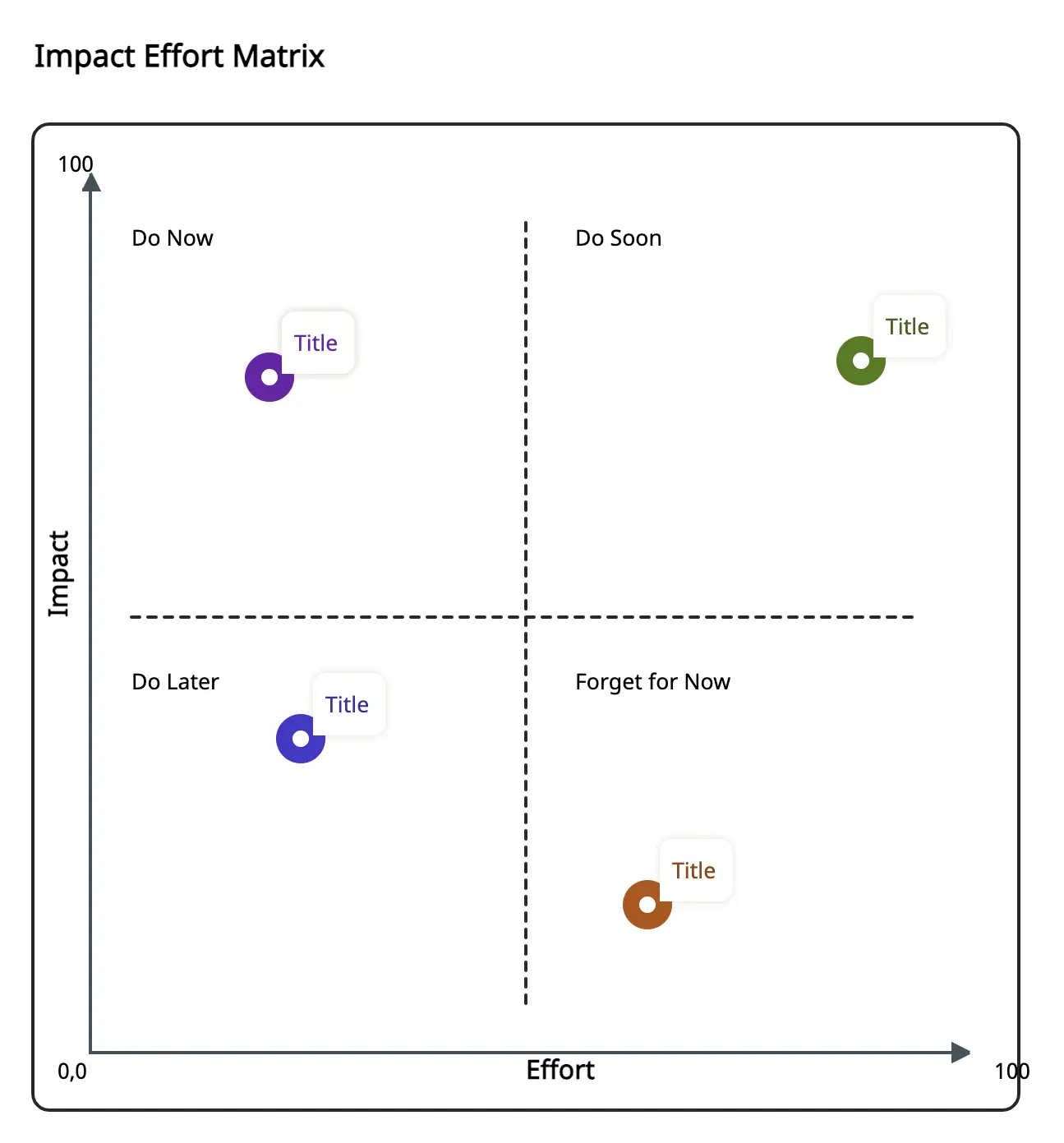

• You may generate several effective solutions to the root cause, but implementing them all would not be practical. Therefore, you will have to select the most practical solutions.

To do this you can use an impact effort matrix . It will help you determine which solution has the best impact and the least effort/ cost.

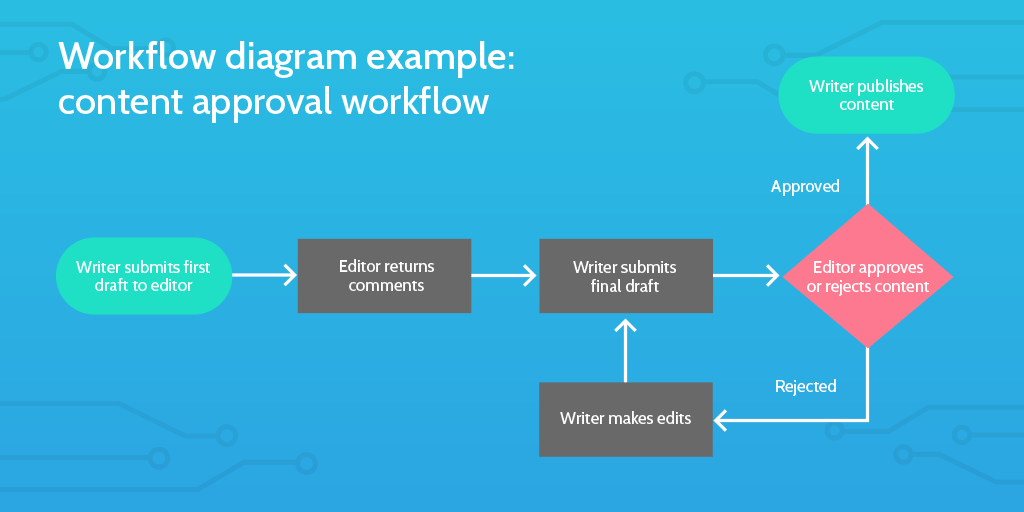

• Based on different solutions, you should develop new maps that will reflect the status of the process once the solution has been applied. This map is known as the to-be map or the future-state map. It will provide guidance for the team as they implement changes.

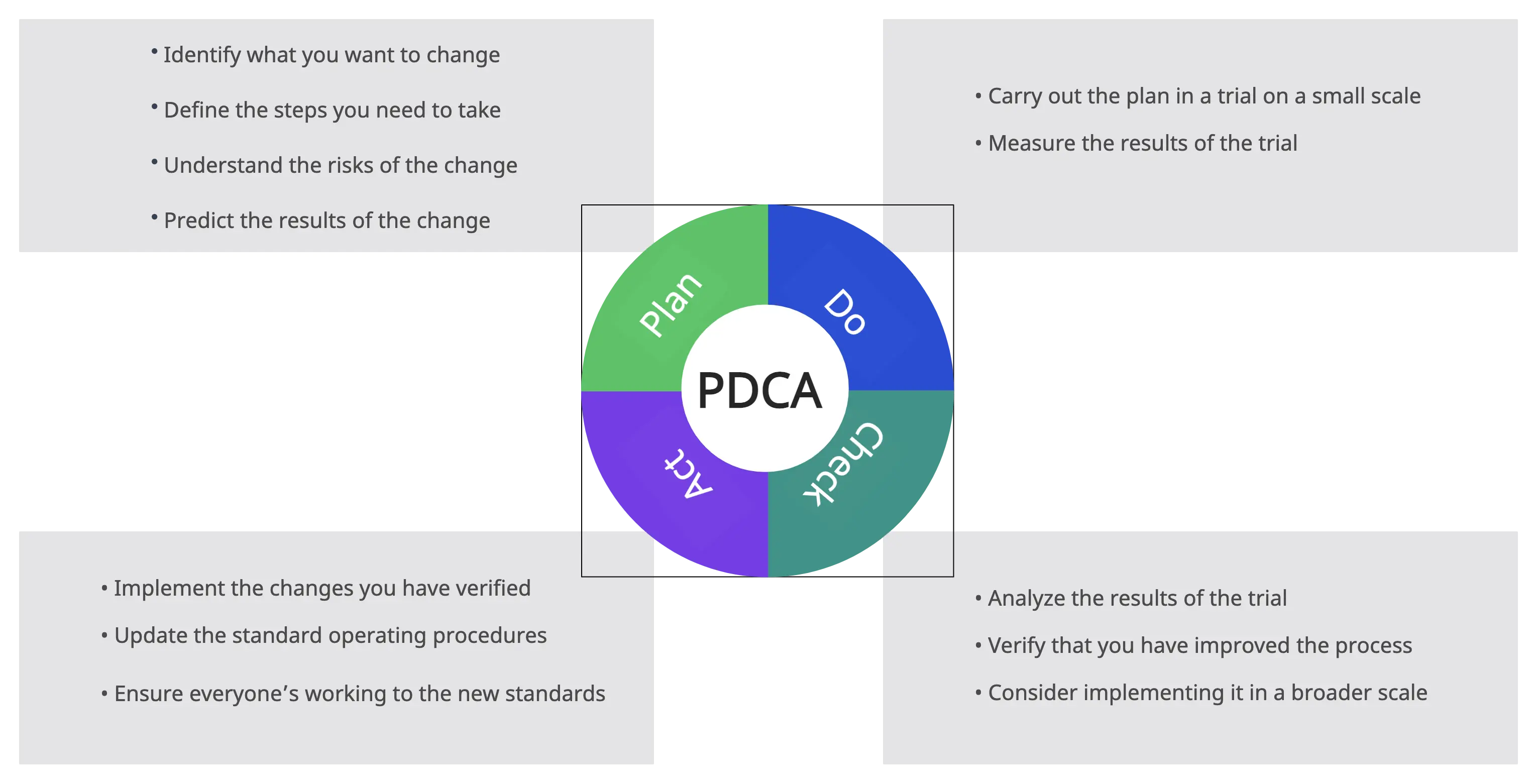

• Explore the different solutions using the PDCA cycle and select the best one to implement. The cycle allows you to systematically study the possible solutions, evaluate the results and select the ones that have a higher chance of success.

Step 5: Control (Sustain the Improvements)

In the final phase of the DMAIC method , the focus falls on maintaining the improvements you have gained by implementing the solutions. Here you should continue to measure the success and create a plan to monitor the improvements (a Monitoring plan).

You should also create a Response plan which includes steps to take if there’s a drop in the process performance. With new process maps and other documentation, you should then proceed to document the improved processes.

Hand these documents along with the Monitoring plan and the response plan to the process owners for their reference.

Insufficiently defining the problem can lead to a lack of clarity regarding the problem statement, objectives, and scope. Take the time to clearly define the problem, understand the desired outcomes, and align stakeholders' expectations.

Failing to engage key stakeholders throughout the DMAIC process can result in limited buy-in and resistance to change. Ensure that stakeholders are involved from the beginning, seeking their input, addressing concerns, and keeping them informed about progress and outcomes.

Collecting insufficient or inaccurate data can lead to flawed analysis and incorrect conclusions. Take the time to gather relevant data using appropriate measurement systems, ensure data accuracy and reliability, and apply appropriate statistical analysis techniques to derive meaningful insights.

Getting caught up in analysis paralysis without taking action is a common pitfall. While analysis is crucial, it’s equally important to translate insights into concrete improvement actions. Strive for a balance between analysis and implementation to drive real change.

Failing to test potential solutions before implementation can lead to unintended consequences. Utilize methods such as pilot studies, simulation, or small-scale experiments to validate and refine proposed solutions before full-scale implementation.

Successful process improvement is not just about making initial changes ; it’s about sustaining those improvements over the long term. Develop robust control plans, standard operating procedures, and monitoring mechanisms to ensure the gains achieved are maintained and deviations are identified and corrected.

Applying DMAIC in a one-size-fits-all manner without considering the organization’s unique culture, context, and capabilities can hinder success. Tailor the approach to fit the specific needs, capabilities, and culture of the organization to enhance acceptance and implementation.

In the project management context, the Define phase involves clearly defining the project objectives, scope, deliverables, and success criteria. It entails identifying project stakeholders, understanding their expectations, and establishing a project charter or a similar document that outlines the project’s purpose and key parameters.

The Measure phase focuses on collecting data and metrics to assess the project’s progress, performance, and adherence to schedule and budget. Key project metrics such as schedule variance, cost variance, and resource utilization are tracked and analyzed. This phase provides insights into the project’s current state and helps identify areas that require improvement.

The Analyze phase involves analyzing the project data and identifying root causes of any performance gaps or issues. It aims to understand why certain project aspects are not meeting expectations. Techniques such as root cause analysis, Pareto charts, or fishbone diagrams can be used to identify factors impacting project performance.

In the Improve phase, potential solutions and actions are developed and implemented to address the identified issues. This may involve making adjustments to the project plan, reallocating resources, refining processes, or implementing corrective measures. The goal is to optimize project performance and achieve desired outcomes.

The Control phase focuses on monitoring and controlling project activities to sustain the improvements made. It involves implementing project control mechanisms, establishing performance metrics, and conducting regular reviews to ensure that the project remains on track. Control measures help prevent deviations from the plan and enable timely corrective actions.

What are Your Thoughts on DMAIC Problem Solving Method?

Here we have covered the 5 phases of Six Sigma DMAIC and the tools that you can use in each stage. You can use them to identify problem areas in your organizational processes, generate practical solutions and implement them effectively.

Have you used DMAIC process to improve processes and solve problems in your organization? Share your experience with the tool with us in the comment section below.

Also, check our post on Process Improvement Methodologies to learn about more Six Sigma and Lean tools to streamline your processes.

Join over thousands of organizations that use Creately to brainstorm, plan, analyze, and execute their projects successfully.

FAQs about Six Sigma and DMAIC Approaches

DMAIC and DMADV are two methodologies used in Six Sigma. DMAIC is employed to enhance existing processes by addressing issues and improving efficiency, while DMADV is utilized for creating new processes or products that meet specific customer needs by following a structured design and verification process.

- Used for improving existing processes

- Define, Measure, Analyze, Improve, Control

- Identifies problem areas and implements solutions

- Focuses on reducing process variation and enhancing efficiency

- Used for developing new products, services, or processes

- Define, Measure, Analyze, Design, Verify

- Emphasizes meeting customer requirements and creating innovative solutions

- Involves detailed design and verification through testing

Problem identification : When a process is not meeting desired outcomes or experiencing defects, DMAIC can be used to identify and address the root causes of the problem.

Process optimization : DMAIC provides a systematic approach to analyze and make improvements to processes by reducing waste, improving cycle time, or enhancing overall efficiency.

Continuous improvement : DMAIC is often used as part of ongoing quality management efforts. It helps organizations maintain a culture of continuous improvement by systematically identifying and addressing process issues, reducing variation, and striving for better performance.

Data-driven decision making : DMAIC relies on data collection, measurement, and analysis. It is suitable when there is sufficient data available to evaluate process performance and identify areas for improvement.

Quality control and defect reduction : DMAIC is particularly useful when the primary objective is to reduce defects, minimize errors, and enhance product or service quality. By analyzing the root causes of defects, improvements can be made to prevent their occurrence.

More Related Articles

Amanda Athuraliya is the communication specialist/content writer at Creately, online diagramming and collaboration tool. She is an avid reader, a budding writer and a passionate researcher who loves to write about all kinds of topics.

DMAIC: The Complete Guide to Lean Six Sigma in 5 Key Steps

One of the core techniques behind any process improvement, particularly in Six Sigma, is DMAIC.

This handy approach, pronounced duh-may-ik, is the key to employing Six Sigma and beginning your journey to being a process hero. We’re going to cover each step in the process and detail how to effectively enact every section.

This guide will lead you through from start to finish and get you ready to start employing lean Six Sigma within your business!

What is DMAIC?

DMAIC stands for:

DMAIC is a data driven improvement cycle designed to be applied to business processes to find flaws or inefficiencies – particularly resulting in output defects – and to combat them. The goal of employing DMAIC is to improve, optimize, or stabilize existing processes.

The development of the DMAIC methodology is credited to Motorola , but is largely a further expansion of systems developed by Toyota. You can read more about how Toyota has employed their process improvement techniques in our article How Toyota Saved Children’s Lives with Process Implementation .

What we’re going to do is look at each stage of the process and consider what needs to be explored and what kinds of tools and methodologies you might use throughout.

Before you dive in, consider reading this DMAIC Case Study to give yourself an overview of the process from start to finish with handy graphs. This case study should help you be able to visualize each step we undertake throughout the article within a broader context.

When do we use DMAIC?

Though we’re not formally recognizing that step within this article, it would be remiss to not appreciate the importance of this addition.

DMAIC cannot be used in all situations. It pertains to specific opportunities for process improvement.

So what are these specific conditions?

There are three main things worth considering when assessing a situation for whether DMAIC would fit:

- There is an obvious problem of some form with an existing process or set of processes.

- The potential is there to reduce variables like lead times or defects while improving variables like cost savings or productivity.

- The situation is quantifiable; the process itself involves measurable data and the results can be appropriately understood through quantifiable means.

Once you’ve recognized whether or not your process is a good fit for DMAIC, you can get started!

Define: Map the project and understand your aims

The Define stage is essentially the planning part of the exercise.

It consists of 7 key sections:

Define Customers and Requirements

How you carry out this stage depends on who your customers are. There are two subsections of customers, either internal customers or external customers .

Internal customers are levels of management within your organization or other departments who are reliant on the output of the particular process you are attempting to improve.

External customers would be the end users of your product or services. These would normally be your business clients but could also be the company’s shareholders.

We tend to divide the expectations of these customers into two related categories: needs and requirements. Needs refer to the end goals of a product: someone buys an air-conditioning unit because they want to keep a room cold. Requirements refer to features or aspects of a product: an air-conditioning unit needs to have a thermostat of some description in order to deliver the cold room the customer needs.

When judging the output of a process, we analyze who the customers are, what their needs are, and what the requirements are to fulfill these needs.

Develop Problem Statement, Goals and Benefits

The next step is to bring that customer information into actionable steps.

We want to develop a clear Problem Statement in order to communicate the purpose of the process and to help us understand how our actions will relate directly to the end results. This should not look to define the solution, but instead focus on the following aspects :

- What is the pain point?

- Where is it hurting?

- When has it been hurting? Is it long term or short?

- What is the extent of the pain?

The Six Sigma Institute provide the following example problem statement:

“In the last 3 months (when), 12% of our customers are late, by over 45 days in paying their bills (what) . This represents 20% (magnitude) of our outstanding receivables & negatively affects our operating cash flow (consequence) .”

In doing so, we should clearly define what our ultimate goals will be from the process improvement work we undertake. This might be identifying something simple like a need to increase output per hour from 100 units to 200 units. Or it might be improving clearly measurable rates of customer satisfaction or other similar quantifiable variables. In a pure Six Sigma approach, your goal would be to improve your Sigma baseline and reduce whatever your defined defects are – but we’ll come to all that later.

The goal statement should be SMART: Specific, Measurable, Attainable, Relevant and Time Bound.

The Six Sigma Institute example:

To reduce the percentage of late payments to 15% in next 3 months, and give tangible savings of 500K USD/ year.

Identify Champion, Process Owner and Team

In order for us to implement this process improvement, we need to determine the roles of different employees in bringing the project to completion. Different companies will put differing emphasis on roles, so take the following as an example as much as a definition.

If you’re familiar with lean methodologies like Scrum, this will quickly make sense to you.

The Process Owner is the person who is responsible for the process improvement project. This is the hands on position where the person involves themselves with each team involved in the process, analyzes and tracks data and output, and looks to manage the process from above from the first step to the last. The Process Owner’s primary function is to provide the planning and overview to allow everyone else to flourish.

The Process Champion is an individual within the organization who has the power to make key decisions and facilitate the work of the Process Owner. This would likely be an executive who can help allocate resources to serve the needs of the Process Owner. The Champion aims to remove barriers which the Process Owner is facing and help facilitate the process improvement project from another step above.

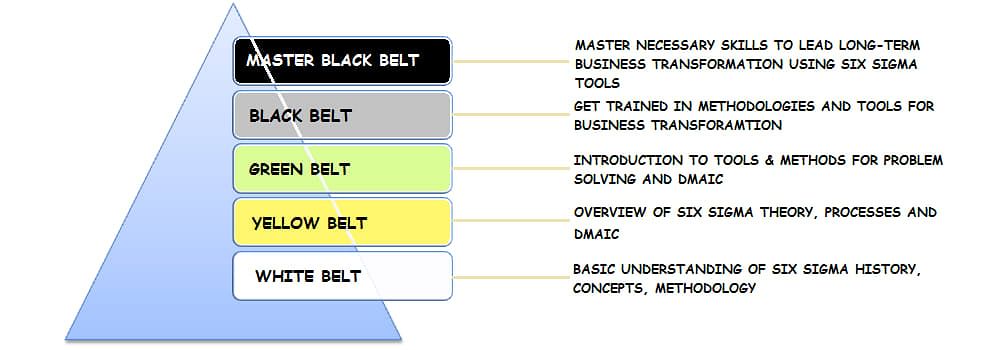

The team in this context are the employees who will be putting the desired changes into action and helping monitor the effects of these changes. The main person in this team is the Black Belt; the project manager for the team. The other employees who focus on the Six Sigma process might be referred to as Green Belts (at this point it starts to feel a little like a karate kid cosplay).

Define Resources

In order to undertake this process improvement project, we need to know what resources are available for the Process Owner to utilize.

This might include a budget for contracting external services, purchasing additional tools, or travel expenditures. It might also refer to how many staff will be needed in order to make this change effectively; do staff need to be brought in from other departments, or will new staff need to be hired?

The amount of resources required will be defined by the problem and goal statements. You don’t want to spend $1 million to save the company half a million. We need to understand what resources are needed to tackle the project and what resources are reasonably available.

Evaluate Key Organizational Support

Now you know what resources you need to begin the project, you need to know what support you can gather from other actors within your organization.

The Process Champion will be in charge of attempting to mobilize this support from other areas of the company. In order to do this, the Process Champion will likely try to create a Business Case.

The purpose of a Business Case is to demonstrate the importance of this process to the broader operations of the company. The Six Sigma Institute give us an example of 7 questions which a Business Case should answer:

- Why is the project worth doing? Justify the resources necessary to engage in the project.

- Why is it important to customers?

- Why is it important to the business?

- Why is it important to employees?

- Why is it important to do it now?

- What are the consequences of not doing the project now?

- How does it fit with the operational initiatives and targets?

The Institute also provides us with an example Business Case:

By reducing the average transaction length, the queue would be able to enhance the Speed of Resolution and assist the end-users in fastest possible manner. This will not only help in achieving client targets but also increase end-user satisfaction score by offering lesser turn-around time.

… although a full Business Case should include more detail and more clearly address each of the above questions.

Develop Project Plan and Milestones

We should now be in a position where we understand the different requirements, the available resources, and role allocation.

At this point, we can begin to develop a detailed project plan with attainable and realistic milestones.

The first step of our project planning is to develop our project scope. In doing so, it is useful to use both longitudinal and lateral scoping. Longitudinal scoping relates to the length of the process, whereas lateral scoping refers to the breadth.

For example, if I was to analyze the process I use to write articles, the longitudinal scope would stretch from having the idea for the article to the moment the article goes live. That’s the scope of the process I would be investigating; with a clear start and end date.

The lateral scope would be the scope of my investigation. Am I going to analyze only the process of writing this article? Am I going to analyze the process repeatedly over a period of 6 weeks? Am I going to analyze my process and the same longitudinal process of my colleagues over that period too?

Think of it as the scope of the process vs the scope of the investigation.

Once we have this in place, we can look to lay out milestones for when different key moments in the DMAIC process will be achieved. What date will we begin the first step of the Measure stage? What date will we commence the Improve stage? When will we complete the DMAIC process?

It is recommended to set aggressive milestones as efficiency savings benefit from being brought in sooner rather than later, naturally. However, setting milestones which are too aggressive can result in what’s called “band-aid” solutions; where quality is sacrificed in order to reach arbitrary targets.

Develop High Level Process Map

This will serve to demonstrate to each individual player where they fit within the process and how their role relates to the next.

You can use tools like LucidChart to help you create process maps and diagrams simply and effectively.

If you want to read more about process mapping and other in-depth process overview techniques you can read this article of ours: BPMN Tutorial: Quick-Start Guide to Business Process Model and Notation

Measure: Gather the data to understand performance

In the next few subsections we’re going to look at some key Six Sigma terms to understand what we’re measuring, then we’ll develop a research methodology and put it into practice.

This step is all about gathering our data!

Define Defect, Opportunity, Unit and Metrics

At the beginning of the Measure stage, we need to first define what we should be measuring.

To do this, we’ll need to understand a couple of key terms :

- Unit in the Six Sigma context refers to a single item of the product. This is our smallest indivisible point of reference.

- Defect refers to a problem with the product which has arisen from an issue in the process.

- Opportunity refers to the potential points within a process where the possibility for a defect occurring is present.

Once we understand these terms, we can see how they start to fit together to help us make decisions:

- Defects per unit (DPU) : number of defects / total number of units

- Defects per opportunity (DPO) : number of defects / (number of units x number of defect opportunities per unit)

- Proportion defective (p) : number of defective units / total number of units

Work out all the possible opportunities for problems and then begin to filter that list to remove extremely rare events, or to group problems with related causes together. This should give you a workable estimation for your Opportunity.

Develop Data Collection Plan

In order for us to make the necessary calculations, we need to gather our data about the process.

To do so we will create a data collection plan which will outline our approach and help us clarify our methods.

This analysis will focus on the minutiae of what exactly we want to measure, how the data will be collected, and the methodology by which we want to handle the data, including:

- How many observations are needed

- What time interval should be part of the study

- Whether past, present, and future data will be collected

If this process improvement project is geared toward internal processes then your customer – another department, for example – might also be gathering this data. This is useful to check because it gives you a control against which you can verify your data once it has been collected, provided any variables are taken into consideration.

The difficulty of this data collection could lie in translating the outcomes into numerical values. For a manufacturing process it is fairly straightforward to understand the process and its outcomes in numerical terms, but less grounded processes can prove trickier. This is why it is important to plan carefully at this stage.

It’s also important to note that while historical data can be used in this analysis, it will likely not have been collected via the same structures and methodologies as you’re creating in this step. This presents a problem as it de-standardizes the data; use historical data with caution.

Having a standardized data collection process gives better data and ultimately better results.

Research 101.

Validate the Measurement System

Well done, you have a research methodology!

But don’t get too excited – we’re not quite ready yet.

Like any piece of research, it is vital to test the methodology – or measurement system – before releasing it into the wild. As a researcher might conduct a pilot study, so too must we test our research methods and review them on a couple of key areas.

There are 4 specific things we want to test before we launch our data gathering project in full:

- Repeatability : If the same operator reaches pretty much the same outcome multiple times on the same item with the same equipment, we can see an adequate level of repeatability.

- Reproducibility : This becomes reproducible if multiple operators measuring the same items with the same equipment end up with the same outcomes.

- Accuracy : It’s a little trickier to be certain on accuracy, but we can broadly say that this can be seen in the difference between an observed average measurement and the associated known standard value.

- Stability : The level of stability is, in a sense, a further extension of repeatability and reproducibility. Stability can be seen by what extent the same operator gets the same outcomes from measuring the same item with the same equipment over a longer period of time. One of the things this stability check is looking for is whether there are external variables which can impact reproducibility over time.

The best way to test your measurement system is to undertake a Gage Repeatability and Reproducibility Study (GR&R), which you can read more about here in this mini library of GR&R materials from iSixSigma .

Once we’re sure that our methodology is clearly defined and we’ve validated our measurement system, we can begin to collect our data!

Collect the Data

Not too much needs to be written about the actual data collection as all the previous steps have been building up to this point.

The key thing to remember is simply to stick to your plan as you defined it and to adhere stringently to the research practices and methods which you validated.

The Black Belt should be the primary point of command in this data collection process, making sure that all procedures are adhered to. The Black Belt needs to take responsibility for all the Green Belts understanding the necessary steps, definitions, and goals.

Begin Developing Y=f(x) Relationship

This is where things will start to sound a little technical. But don’t worry, we’ll walk through it.

Think of Y as representing the output of a process. It doesn’t technically refer to Yield at this point, but we’ll come to that later on.

So, Y is the output of a process and X is the input. The f represents the function of the variable X.

Y is the output we care about and X can be multiple different variables which impact on Y. Here’s an example from iSixSigma :

For example, if you call your major department store to ask a question, the ability to have your question answered (Y) is a function (f) of the wait time, the number of people answering the phones, the time it takes to talk with the representative, the representative’s knowledge, etc. All of these X’s can be defined, measured and improved.

At this point, you don’t need to work out the Y=f(x) relationship in full, but you can start bearing it in mind. It is considered best practice to keep work oriented around the Y=f(x) formula.

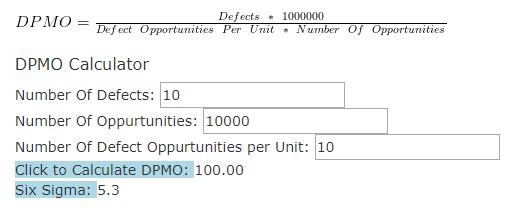

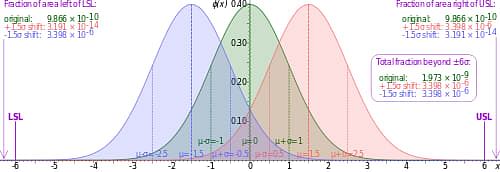

Estimate the Sigma Baseline

Again, we can prepare ourselves for the future stages by running a quick calculation.

To work out your Sigma, you can calculate your Defects per Million Opportunities (DPMO) and run it through a handy conversion chart.

You calculate your DPMO by simply multiplying your DPO by a million.

To make it all easier, just use this straightforward Sigma Calculator .

Analyze: Understand where the problems in your process lie

The analysis step is where we have to dig in deep into the existing processes and work out the root causes of the problems.

Finding these causes should allow us to tackle them in our Improve stage. It’s all about finding the pertinent Xs for the Y=f(x) formula we mentioned above.

Define Performance Objectives

Having measured the process in the previous steps, we should be in a position where we roughly know what it is we want to improve.

Before we begin analyzing in depth, we should lay out what our objectives are so that these goals can guide us. Think through the process and the data you have to calculate what the key performance objectives would be.

These objectives can prove slightly flexible as your analysis moves forward but it is always better to start with clear goals.

Develop a Detailed Business Process Map

We’ve already mentioned in this article how you can use strategies like BPMN to map business processes, but it isn’t the only approach. A very similar approach might be to use an As Is Process Map, which can incorporate BPMN elements but is not defined by it.

This business process map can help show us the granular make up of the company process we are analyzing and reveal factors like which process steps are value added and which are non-value added. Identifying non-value added steps at this stage opens up the potential for us to eliminate waste in our process improvements.

This process map should be analyzed for potential areas of variation. These variations, or potentials for variation, will likely lead us to the root causes behind our Opportunities (for defects).

Determine Root Cause(s)

There are many different techniques you can utilize in order to attempt to dig down into what the root causes of a variation are, and we’re going to look at three specific examples of methods you can use:

The 5 Whys Analysis

The Fishbone Diagram

- The Pareto Chart

This is a fairly simple technique to start you off. The idea is that you ask “why?” five times to dig deep into the root of a problem. The logic behind it is that in the first few questions you will find one of the causes of the problem, and by the 5th question you will see the process failure behind that problem. This example from Wikipedia does an excellent job of conveying it:

The vehicle will not start. (the problem) Why? – The battery is dead. (First why) Why? – The alternator is not functioning. (Second why) Why? – The alternator belt has broken. (Third why) Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why) Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

This approach takes 6 different variable categories and feeds the information together to help you visualize what factors within the business operations are contributing collectively to the same problem. One of the advantages of this method is that it forces us to view the problem holistically, rather than the potentially blinkered approach of the 5 Whys.

According to the Six Sigma Institute , the 6 key variables are:

Machine : This category groups root causes related to tools used to execute the process. Material : This category groups root causes related to information and forms needed to execute the process. Nature : This category groups root causes related to our work environment, market conditions, and regulatory issues. Measure : This category groups root causes related to the process measurement. Method : This category groups root causes related to procedures, hand-offs, input-output issues. People : This category groups root causes related people and organizations.

You might already be familiar with the Pareto Chart. The purpose of the Pareto approach for us is to understand which variations have the highest impact on our output; it helps us determine the Vital Few.

If the other techniques assist in finding variations and identifying potential root causes, the Pareto Chart allows us to prioritize which root causes to target first to have the greatest impact on improvement in relation to our stated objectives.

Determine the Y=f(x) Relationship

Once we’ve identified the Vital Few, we’re able to return to our Y=f(x) formula.

Remember, Y is simply a variable which is defined by the relationship between our Xs and their functions. So, if we want to improve Y then we should identify which X has the biggest impact on the Y value and improve that X.

Our ultimate aim is to better understand the relationship represented by this formula and to round out errors from it. For example, there may be an X which has a major impact on Y but is not due to a process problem but simply a natural or unchangeable element of the manufacturing process. In which case, we need to identify that this particular X, while important, is not one we can tackle as part of our process improvement.

Our job isn’t just to find the Xs which contribute to Y, but to find the right Xs.

Improve: Work out how defects could be reduced

The improve section of the DMAIC process is where we take advantage of all the preparatory work we’ve done so far.

Our goal here is to highlight our Xs and look to maximize the performance of those inputs. The key element of the Six Sigma approach is the importance of doing this through mathematical and scientific means.

Perform Design of Experiments

Our Design of Experiments (DOE) is probably the key step to getting this right and achieving the improvements we want to make.

This DOE approach highlights the relationships between different Xs and the output (Y). Factorial experiments are one of the crucial methods to show how different Xs can relate to each other.

Controllable input factors .

These are your Xs. These are variables within the process which we can experiment with and change. In baking a cake this might include the number of eggs or the amount of flour.

Uncontrollable input factors .

These are variables which may have arisen earlier in the investigation but we can’t act upon. In a baking scenario it might refer to the resting temperature of the kitchen. Or, to make an infrastructural analogy, the capacity of the oven – a factory might produce more goods if it was bigger, but increasing its size might be prohibitively expensive, for example.

Responses .

This is the extent to which the output services the customer needs and wants. In baking this could refer to a simple taste test. This factor, like the others, would need to be quantified. “Good or bad” is not enough; a score out of 10 from the customer averaged out as a final percentage figure from all testing would be a more effective approach.

Hypothesis testing .

In a hypothesis test there are two potential outcomes: null and alternative. A hypothesis test focuses the accuracy of a hypothesis with each test. The null hypothesis is valid if the status quo is true. The alternative hypothesis is true if the status quo is not valid. We get our results by analyzing significance which means results are based on probabilities – so get your p-values at the ready!

In baking, we might have a brand name cake mix which declares that it takes on average 30 minutes to bake. You might classify this as your hypothesis. The null hypothesis would be that the average amount of time it takes to bake this particular cake is in fact 30 minutes. But you can’t have a null hypothesis without an alternative hypothesis. You should select your alternative hypothesis in advance in order to construct the experiment properly. We have 3 choices of alternative hypotheses to choose from:

- The average time to bake the cake is not 30 minutes (not equal)

- The average time to bake the cake is more than 30 minutes (greater than)

- The average time to bake the cake is less than 30 minutes (less than)

The formula for checking whether the average baking time is 30 minutes or not would be:

Ho:μ=30 versus Ha:μ≠30

Blocking and Replication .

Blocking and replication are fortunately much simpler concepts. Blocking is just about making sure the conditions for each experiment are the same; use the same stirrer and tray to bake the cakes with. And replication is simply the principle of running the experiment multiple times to gain more accurate results – a great excuse to bake extra cakes.

Interaction .

This refers to a situation where an experiment has three or more variables and the simultaneous influence of two of the variables on the third is not additive. Sadly, my knowledge of baking has let the analogy down on this one. My bad.

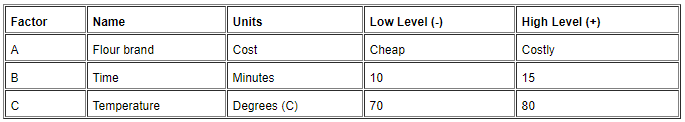

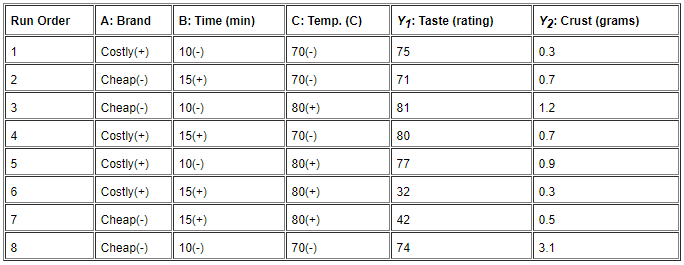

Two-Level Factorial Design

This experiment will be constructed to look at 3 variables where each can be tested at a low or high level. This kind of structure gives us the ability to investigate deeper into a process yet is still simple enough for us to see how the experiment works.

Consider our process to be baking a cake. Our three variables are the Vital Few we identified in our Analysis stage. They are:

- Brand of flour

- The temperature of baking

- The baking time

Taste-testing will be a score out of 10 with the average multiplied by 10 to give a percentage result. The crust-formation will be measured by weight with lighter crusts being the goal.

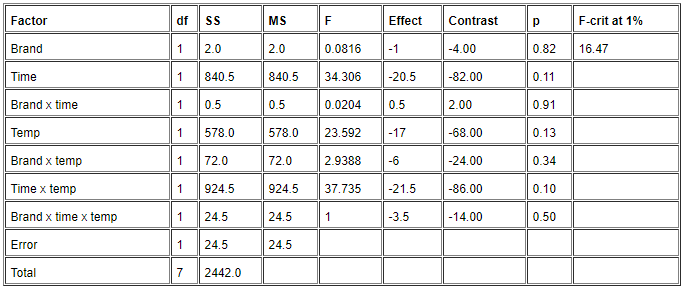

The simplest overview of ANOVA tables can be found here , and it gives us this handy summary:

It doesn’t look at the differences between pairs of group means; instead, it looks at how the entire collection of group means is spread out and compares that to how much you might expect those means to spread out if all the groups were sampled from the same population (that is, if there were no true differences between the groups).

Which means roughly that our ANOVA table on taste testing will look at how all the results impact on taste to see how each group should impact on taste and then tells us how each group performs relative to that expected impact; higher or lower impact.

All this is conveyed through the F Ratio which tells us about the levels of variance between the groups relative to the variance within the groups.

If the null hypothesis is true, then F should be close to 1. The further F is from 1 the more it suggests the alternative hypothesis to be true. In the case of our experiments, the higher F is the more important an input factor is on output.

Develop Potential Solutions

With a strong working knowledge of your business processes and systems, you’re now able to develop solutions which can tackle the key issues hindering output within the business.

The results of the DOE tests can also assist in that optimization process as the visual graph above shows. This data gathered from varying iterations of your key potential Xs, provides a series of potential avenues to explore.

When constructing the different options for solutions make sure to propose enough to test and evaluate.

These solutions should be rooted in the deep analysis you’ve undertaken.

Assess Failure Modes of Potential Solutions

Failure Modes and Effects Analysis is a method which can identify risk ahead of time. This quasi-predictive process analysis tool can help you evaluate the details of your proposed business process solutions.

You can read more about FMEA in a previous article of mine: FMEA: The Analysis Method to Prevent the £100m British Airways Catastrophe .

Validate Potential Improvement by Pilot Studies

Lastly, to complete the Improve section of our DMAIC process, it’s important to test out the solutions which have made it to this point.

The few solutions you’re left with can be part-deployed live in controlled conditions as part of a pilot study to gage their relative effectiveness.

The Process Owner can map out the design for these pilots and the Black Belt can manage the pilots in practice.

The performance of the proposed solutions should leave you with an overall best performing process improvement solution based on output. To measure these proposed solutions effectively, try to calculate the Sigma Baseline as before.

Control: Plan out how you will implement your solutions

The Control section is all about putting processes and procedures in place to make sure the implementation of the new solution runs smoothly and can be tracked and optimized over time.

Ultimately, the rest of the DMAIC process prior to this stage was dedicated to the Xs whereas the Control stage is devoted to the Y; the output.

Standardize and Document Processes

This is the most obvious step and echoes what we always discuss in our articles on Process Street .

To implement a new process, you need to make sure each step is documented thoroughly and it is mapped out in a way which is actionable and provides space for measurement.

These processes should be consistent at all times and this can be achieved through simply standardizing approaches across teams.

Prepare Implementation Plan

This task may be planned by the Process Owner and implemented by the Black Belt, though different companies might look to do it in different ways.

The important factors here concern how the new process can be effectively integrated into the company workflow .

- What teams within the company need to adapt to suite the new process?

- Does this change need to be simultaneous or can it be rolled out iteratively?

- Do we require multiple Six Sigma advocates to embed into each team for implementation?

- What budget or resources does the Champion need to secure to ensure effective rollout?

- When does implementation begin?

- What is the target date for complete implementation of the new process?

All of these questions should be answered in the drafting of a report so that the company can act upon our DMAIC work.

Additionally, it is important to create a Response Plan which tackles the what ifs of managing the process. This would come under the realm of risk management as it looks at putting processes and procedures in place for if problems occur within the process or are seen in the output.

Implement Statistical Process Control

Once your process is standardized and documented, implementation must undergo monitoring. One industry standard approach to process monitoring is Statistical Process Control.

Statistical Process Control (SPC) was originally developed in 1924 by Walter Shewhart. It is used to monitor and control the output parameters of a process.

A short definition is given to us by InfinityQS :

Quality data in the form of Product or Process measurements are obtained in real-time during manufacturing. This data is then plotted on a graph with pre-determined control limits. Control limits are determined by the capability of the process, whereas specification limits are determined by the client’s needs.

This basically means that we gather quantifiable data about the process and look at the size of the output vs the quality of the output.

On the graph you make, you’ll set control limits. These define an acceptable range which your process should operate within. When data points start appearing outside of this range, this acts as a red flag to show us that variations are occurring.

If done properly, these red flags should catch variations before variations result in defects; allowing us to tackle process problems before they result in output or product problems.

Use DMAIC to help you reach your Six Sigma goals

Once you’ve successfully undertaken your DMAIC project, you might think your job is done.

A crucial part of any lean Six Sigma process is to keep the principle of continuous improvement in mind. Within lean philosophies we might refer to this as Kaizen. In Japanese this translates to “change for better”, but within the world of process improvement it has come to reflect a continuous iterative model for gradual change.

Once one Six Sigma project is done, it is likely time to move onto the next.

If you can reach your goal of Six Sigma then your processes will be functioning at the highest industry standards and your business will be in the best position it can be.

It’s up to you to make sure the rest of the business runs as effectively as your best processes!

Are you a Six Sigma enthusiast? Have you employed DMAIC in your business before? Let me know in the comments your experiences, tips, and tricks!

Get our posts & product updates earlier by simply subscribing

Adam Henshall

I manage the content for Process Street and dabble in other projects inc language exchange app Idyoma on the side. Living in Sevilla in the south of Spain, my current hobby is learning Spanish! @adam_h_h on Twitter. Subscribe to my email newsletter here on Substack: Trust The Process . Or come join the conversation on Reddit at r/ProcessManagement .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Wiki , Six Sigma

DMAIC Model | The 5 Phase DMAIC Process to Problem-Solving

- 5 mins to read

- July 1, 2020

- By Reagan Pannell

Summary: An Introduction to DMAIC

Dmaic – the dmaic model.

The 6 Sigma DMAIC model remains the core roadmap for almost all Lean Six Sigma problem-solving approaches that drive quality improvement projects. It is used to ensure a robust problem-solving process is followed to give the best chance of the best solution being found.

A note about the structure and the approach used in this article.

Our approach to DMAIC follows Quentin Brook’s book “Lean Six Sigma & Minitab” which for anyone wishing to study Lean Six Sigma is a must for the Green Belt Course and the Black Belt Course .

What is the dmaic model.

DMAIC is short for: Define, Measure, Analyse, Improve and Control. These are the key phases that each project must go through to find the right solution. This flow is the concept behind DMAIC Analysis of an issue and its the DMAIC cycle all projects must go through.

As you can quickly see from the 5 DMAIC phases they follow a logical sequence as we will go through in more detail below. But they also make sure you do not try to jump to implementing a solution before you have properly, defined and measured what you are going to be an improvement.

We all love to jump to solutions, but the DMAIC problem-solving structure helps us have a more rigorous approach so that we do not short cut the process and perhaps miss the best solution or perhaps implement the wrong solution as well. It can help companies better structure their problem-solving approaches and be more robust in their approach.

DMAIC – The 5 DMAIC Process Phases

The phases throughout the DMAIC model have and can be broken down in many different ways. One of the best approaches we have found is from Opex Resources which shows how to examine the existing processes, and with a project team, and the sigma improvement process, we can solve complex issues.

DMAIC Define Phase

The purpose of the Define phase is ultimately to describe the problems that need to be solved and for the key business decision-makers to be aligned on the goal of the project. Its about creating and agreeing the project charter .

All too often, teams have identified solutions without actually defining what it is they will actually be trying to do or perhaps not do. This can lead to internal confusion and often solutions which completely miss the business requirements and needs.

- Define the Business Case

- Understand the Consumer

- Define The Process

- Manage the Project

- Gain Project Approval

DMAIC Measure Phase

In the measure phase, the goal is to collect the relevant information to baseline the current performance of the product or the process. In this stage, we want to identify the level of “defects” or the errors that go wrong and use the baseline to measure our progress throughout the project.

The key goal of this phase is to have a very strong and clear measure/baseline of how things are performing today so that we can always monitor our progress towards our goals. We need to understand our cycle times , process times, quality metrics.

Many projects are delivered without clear benefits being shown because the team never fully baseline the current status before making changes.

The Measure phase can be broken down into 5 key areas:

- Develop Process Measures

- Collect Process Data

- Check the Data Quality

- Understand Process Behaviour

- Baseline Process Capability and Potential

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

We can’t solve problems by using the same kind of thinking we used when we created them” Albert Einstein Tweet

DMAIC Analyse Phase

The goal of the DMAIC Analyse phase with the lean six sigma improvement process is to identify which process inputs or parameters have the most critical effect on the outputs. In other words, we want to identify the root cause(s) so that we know what critical elements we need to fix.

During this phase, the teams need to explore all potential root causes using both analytical approaches, statistical approaches or even graphical tools such as VSM’s and Process maps to uncover the most important elements which need to be changed/fixed.

The Analyse phase can be broken down into:

- Analyse the Process

- Develop Theories and Ideas

- Analyse the Data

- and finally, Verify Root Causes

DMAIC Improve Phase

The goal of the improvement phase is to identify a wide range of potential solutions before identifying the critical solutions which will give us the maximum return for our investment and directly fix the root cause we identified.

During this phase, the team brainstorm, pilot, test and validate potential improvement ideas before finally implementing the right solutions. With each pilot, the team can validate how well it improves the key measures they identified back in Define and Measure. When the team finally roll out the solution, the results should be seen if the right solution has been found and implemented correctly.

The Improve phase can be broken down into:

- Generate Potential Solutions

- Select the Best Solution

- Assess the Risks

- Pilot and Implement

DMAIC Control Phase

The final part of the DMAIC Model is the Control phase where we need to ensure that the new changes become business as normal and we do not revert to the same way of working as before.

During this phase, we want to ensure that we close the project off by validating the project savings and ensuring the new process is correctly documented. We also need to make sure that new measures and process KPI’s are in place and, finally that we get the business champion to sign off on both the project and the savings. We may need to redesign the workplace following the 5S principles .

The Control phase can be broken down into:

- Implement Ongoing Measurements

- Standardise Solutions

- Quantify the Improvement

- Close The Project

The key closing documents of the Control Phase is a Control Plan that documents all the changes and process steps with key risks, standard work instructions and the Project Close-Out document signed by the business owners to accept the change and the validated benefits.

The DMAIC Model vs. A3 Management vs. 8D Problem Solving

The DMAIC model is not the only project management roadmap. Two others which are important is the A3 format which originally comes from Toyota and is very Lean focused and the 8D which draws more of the DMAIC structure but with the 1-page idea of the A3.

Everyone has their own preference but each method is interchangeable. The DMAIC Structure lends its self naturally to a multi-slide Powerpoint presentation. Whereas the A3 is a single-page document which is perfect for internal communication and adding into War Rooms and Control Towers.

What’s important is that every problem-solving approach follows the PDCA (Plan, Do, Check and Act) Scientific Problem Solving format. The reset is just a preference or using the right tool in the right circumstances.

- Corporate Training

- Courses for Individuals

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

Fundamentals of lean.

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, maximising efficiency and profitability: exploring the benefits of lean consultancy, empowering leaders: the imperative for problem-solving training, view all articles, green belt course, other articles, how to improve your decision making | learn what is noise, how to get lean six sigma green belt certified, the benefits of continuous improvement, what qualities do employers look for in potential employees, get your company to fund your lean six sigma training, what is the % defective in lean six sigma, what is jidoka what does jidoka mean | leanscape, sources of measurement error – bias and precision, kaizen vs kaikaku – understanding the difference, 6 sigma control charts – statistical process control charts, why the fmea is a great tool for all project managers, related articles, agile project management: a comprehensive guide, how to use lean six sigma programs to build cash flows, pareto’s principle: the 80/20 rule, online business courses free: the benefits for professionals, harnessing the wisdom of lee kuan yew for personal and professional growth, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

- Quality Management

Home » Free Resources » »

Five Phases of Lean Six Sigma: A Complete Guide

- Written by Contributing Writer

- Updated on March 21, 2023

Customer expectations and behavior are constantly changing. Competition in nearly every industry seems to be intensifying. Profitability and growth now depend in large part on the efficiency of products and services and their speed to market.

Six Sigma is a process that organizations employ to optimize business processes for the most efficient and cost-effective approach while producing continuous product improvements.

In this article, we’ll explain the Six Sigma methodology, explore its benefits and challenges, and detail the five phases of Lean Six Sigma with examples.

What is the Six Sigma Methodology?

The Six Sigma methodology identifies defects and roadblocks that hinder performance, enabling companies to use strategies to streamline processes, decrease production variation, and improve the quality of products and services.

Six Sigma is a data-driven approach to establishing a culture committed to continuous process improvement. When implemented effectively and consistently, Six Sigma provides a framework for repeatable and systematic problem-solving.

Also Read: Six Sigma Methodologies for Process Improvement

What Is the Difference Between Six Sigma and Lean Six Sigma?

Six Sigma focuses on creating rigid consistency to reduce process variation and enhance process control. Lean Six Sigma eliminates processes that do not add value to promote more streamlined workflows.

In short, Six Sigma emphasizes reduction in variation using processes such as:

- Statistical data analysis

- Design of experiments

- Hypothesis testing

Lean Six Sigma focuses on reductions in waste using processes such as:

- Workplace organization

- Visual controls

In most cases, organizations today incorporate both methodologies into their Six Sigma quality management practices.

What Are the Benefits of Six Sigma?

The benefits of Six Sigma and the DMAIC process include:

Improvements in Quality

By focusing on identifying and eliminating defects and wasted steps in processes, organizations can improve the quality of operations and products or services.

Increases in Efficiency

Six Sigma identifies roadblocks and inefficiencies in systems. Efficiency and productivity gains provide significant results in many cases. In manufacturing, for example, these efficiencies can improve quality, turnaround times, and cycle times for equipment.

More Efficient Decision Making

By putting quantifiable data at the heart of decisions, organizations can reduce making decisions based on intuition or assumptions. Instead, decisions are made based on facts and evidence and are measured against baselines for continuous improvement.

Improved Customer or End-User Satisfaction

When organizations can streamline processes to produce faster or higher-quality results, it improves customer satisfaction. This, in turn, can generate more loyal customers and higher customer retention levels.

Cost Savings

There can be significant financial benefits from implementing a Six Sigma methodology. Increased efficiency reduces waste and defects, creates efficiencies and streamlines processes, and produces better customer satisfaction.

Competitive Advantage

Organizations that utilize the five phases of Lean Six Sigma methodology can gain a competitive advantage in several ways, including delivering higher-quality products or services more efficiently and cost-effectively than their competitors.

Employee Engagement

Not to be overlooked in the five phases of Six Sigma are the benefits to employee engagement. Project teams typically include employees from various disciplines. Working together to understand problems and develop solutions encourages teamwork and is fundamental to creating a culture of continuous improvement.

Involving team members in the process also creates buy-in since team members have a stake in the success of the Six Sigma process.

Also Read: Six Sigma Principles: A Comprehensive Guide to Implementing and Optimizing Your Processes

What is DMAIC?

DMAIC is an acronym for the five phases of Six Sigma.

The DMAIC phases are an iterative process used to seek quality improvement by focusing on the process to create more efficient and permanent solutions. DMAIC provides the structure to the process, enabling project teams to use specific tools and deliverables that lead to process improvements. While most teams work through DMAIC in a linear fashion, it isn’t mandatory to do it this way. The process itself encourages team members to backtrack to previous steps, especially when additional information or insight is needed.

The Five Phases of Lean Six Sigma

Each of the five phases of Six Sigma is data-driven and focuses on standardizing an organization’s approach to problem-solving. So, let’s dig deeper into the DMAIC phases.

Phase 1: Define

In the define stage, team members work together to identify the information they’ll need to break down components of a problem or process and create smaller actionable terms. Rather than focusing on abstract goals, it seeks quantifiable and qualifiable data to clearly identify the objective of the project.

Teams will identify the Critical to Quality (CTQ) attributes as determined by the end-user or customer — called the voice of the customer (VOC) — and create a process map, including process inputs and process outputs.

For example, a manufacturing company has identified a problem somewhere in their production process that is leading to product defects outside of acceptable ranges but doesn’t know where or why these defects occur. In the define phase, they would design the project scope and establish objectives, such as reducing the number of acceptable defects in the production process to a specific number.

Phase 2: Measure

The measure step of the DMAIC phases of the Six Sigma process assesses current processes and capabilities. While the goal is to make process improvements, teams need a clear understanding of the current conditions to judge the effectiveness of any future changes. Without a baseline, it’s hard to measure if you’ve made any progress.

In this phase, team members will measure the current process and create a baseline for future comparison.

For example, this phase would identify the frequency of the defects and information about potential causes, such as production line speed or equipment breakdowns, deviations in material or suppliers, or other mitigating factors.

Phase 3: Analyze

The analysis phase of the Six Sigma methodology takes a deep dive into the data that’s been gathered to isolate root causes of inefficiencies and identify defects. Teams in this phase often create detailed subprocess maps for every step with the goal of eliminating and streamlining steps to improve performance and quality.

Teams might deploy several analysis tools, such as Pareto charts or fishbone diagrams, to analyze the root causes of the high defect rate.

Teams also analyze the performance and financial benefits of solving a problem or improving a process.

Phase 4: Improve

After identifying the root cause of any issues, this phase focuses on finding the solution or improvement. Common methods include deploying a design of experiment model to isolate variables and test hypotheses until obstacles are uncovered.

Once process improvements are identified, teams create a proposed solution and then implement pilot programs to test, ensuring solutions meet project objectives and are financially viable.

As an outcome of analyzing the data, teams might redesign the production process, recommend upgrading equipment or maintenance procedures, or provide additional training to operators.

Phase 5: Control

The final step of the five phases of Lean Six Sigma involves documentation of the solutions created for process owners. This includes actionable steps, timelines, and milestones for implementation. In this phase, the control plan details the daily workflow.

The project team then monitors the project for a prescribed period to make sure the process meets performance expectations in real-world environments before turning it over to process owners.

In the control phase, organizations might implement control charts to tightly monitor production output and defect rates, the impact of operator training, and any other solutions deployed.

Each of the five phases of Six Sigma works together to create a repeatable template for improving business processes. When fully integrated into an organization’s culture, it enables teams to innovate new solutions, measure effectiveness and efficiency, and create quantifiable process improvements.

Also Read: Six Sigma vs. Lean Six Sigma: Which Methodology Is Right for Your Business?

Challenges with Implementing Six Sigma

Even though Six Sigma can help your team become more efficient and cost-effective, there are implementation challenges when it comes to DMAIC phases.

The five phases of Lean Six Sigma examine increasingly minute details and micro-steps in every aspect of task completion. This can be challenging for team members to accomplish without experienced project managers that are trained in Six Sigma methodologies. Organizations need team members that understand statistical training and quantifying data points effectively in order to successfully implement this methodology — it’s not something you can pick up on the fly.

Implementing Six Sigma Tools

There’s also a learning curve for the diverse set of tools required to uncover root causes and validate potential solutions. Throughout the DMAIC process, teams may need to be proficient in using tools such as:

- Pareto charts

- Gage R&R

- Process capability upper and lower bounds

- Attribute agreement analysis

- ANOVA statistical modeling

- Regression equations

- Control charts

- Statistical process control (SPC)

- Value stream mapping

Other tools may also be needed depending on industry and functionality. As you can see, some of these tools are incredibly specific and scientific, so it can be tricky to implement if someone on your team isn’t familiar enough with them while going through the five phases of Lean Six Sigma

Organizational Commitment

Effective Six Sigma implementation required buy-in across the wider organization, starting at the very top. Without proper funding, resources, and continued support, the process can be ineffective. In some cases, this leads to incomplete solutions, lack of follow-through, or failure to embrace workplace changes.

To be successful, Six Sigma needs to be embraced and become part of the company culture.

Also Read: Value Stream Mapping in Six Sigma

Fast Track Your Career in Quality Management

Efficiently deploying Six Sigma methodologies and DMAIC phases requires training and expertise. Professionally-trained and certified Six Sigma professionals can make substantive contributions to organizational improvement and earn a lucrative career as a Six Sigma expert.

If you are looking to fast-track your career in Quality Management, an accredited Six Sigma course can help. You can get hands-on experience and mentoring as you solve real-world business processes and learn about:

- Agile management

- Lean management

- Six Sigma Green Belt

- Lean Six Sigma Black Belt

- Quality management

- Digital transformation

Become a Lean Six Sigma Expert with the post graduate program delivered by Simplilearn in collaboration with the University of Massachusetts. Download the program brochure to learn more about the Lean Six Sigma course. This program is accredited by the International Association for Six Sigma Certification (IASSC) and has professors who can share real-world experiences to help bring these complicated concepts to life.

You might also like to read:

The Top 24 Lean Six Sigma Interview Questions for 2023

Six Sigma Methodologies for Process Improvement

Ultimate Guide to Six Sigma Control Charts

Process Mapping in Six Sigma: Here’s All You Need to Know

What Are the Elements of a Six Sigma Project Charter?

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Recommended Articles

What Is Lean Management? Principles & Everything You Need to Know

Discover the essence of lean management – a powerful approach to streamline processes and maximize efficiency. Explore its principles and benefits in our comprehensive guide.

What is Process Mapping in Six Sigma? Here’s Everything You Need to Know

Demystifying Process Mapping in Six Sigma: Learn to optimize workflows and enhance quality. Dive into this essential quality management tool.

Six Sigma Black Belt Salaries in 2024: Everything You Need to Know!

Get to know about salaries and factors affecting six sigma black belt salary and the skills required to have an incremental effect on your pay scale.

A Guide to Failure Mode and Effects Analysis

Explore Failure Mode and Effects Analysis with our easy-to-understand guide. Learn what it is, why it’s useful, how to use it, and its key applications.

A Guide to Design of Experiments in Six Sigma

In today’s hypercompetitive world, organizations must streamline their operations and workflows to stay ahead of the game. Lean Six Sigma and the design of experiments are methodologies that can help them do this. Learn more in this article.

A Guide to Six Sigma Projects

Originally developed for manufacturing processes, the Six Sigma methodology is now leveraged by companies in nearly all industries. In this article, we will share information about successful Six Sigma projects, methods, and more.

Lean Six Sigma Certification

Learning Format

Online Bootcamp

Program benefits.

- Green and Black Belt exam training material included

- Aligned with IASSC-Lean Six Sigma

- Masterclasses from top faculty of UMass Amherst

- UMass Amherst Alumni Association membership

Six Sigma Study Guide

Study notes and guides for Six Sigma certification tests

DMAIC Overview

Posted by Ted Hessing

DMAIC is Six Sigma’s signature framework for process improvement. It provides a structured way of improving a process.

Key Attributes

A DMAIC improvement process:

- Is data-driven.

- Is followed in a strict sequence.

- Uses all five steps.

The Five DMAIC Stages

The five stages we use are:

- Define : Collate what we already know about the existing process.

- Measure : Collect further data about the existing process.

- Analyze : Identify the core problems that we’ll address.

- Improve : Plan, test, and implement solutions.

- Control : Set up supports to ensure that successful solutions are sustainable.

Note how this is reminiscent of the Deming wheel or Shewhart Wheel: Plan-Do-Study-Act ).

History of DMAIC

Michel Harry & Bill Smith created “MAIC” – the methodology that evolved to become DMAIC.

Harry includes the following strategy elements in the traditional approach to Six Sigma:

- (R) Recognize the true state of your business

- (S) Standardize the systems that prove to be best-in-class

- (I) Integrate best-in-class systems into the strategic planning framework.

What’s the difference between Six Sigma and DMAIC?

Six Sigma and DMAIC are closely related, as DMAIC is the problem-solving methodology used in Six Sigma. Six Sigma is a data-driven approach to process improvement that aims to minimize defects and variability in products and services. It uses statistical analysis and other tools to identify and eliminate the root causes of defects, and ultimately improve business performance.

DMAIC, on the other hand, is the acronym that describes the five-step problem-solving process used in Six Sigma projects. It stands for Define, Measure, Analyze, Improve, and Control. DMAIC provides a structured and disciplined approach to problem-solving that enables organizations to achieve Six Sigma levels of quality and efficiency.

Can you use DMAIC outside of Six Sigma?

Absolutely! DMAIC can be used for non-Six Sigma purposes as well.

DMAIC is a structured and disciplined problem-solving methodology that can be applied to a wide range of industries and situations beyond just Six Sigma. The five steps of DMAIC (Define, Measure, Analyze, Improve, and Control) provide a framework for identifying and eliminating problems, improving processes, and achieving better outcomes.

For example, DMAIC can be used in healthcare to improve patient care processes, reduce medical errors, and increase patient satisfaction. In the software industry, DMAIC can be used to identify and fix software bugs, improve user experience, and optimize software development processes. In construction, DMAIC can be used to improve safety practices, reduce waste, and increase productivity.

The key benefit of using DMAIC outside of Six Sigma is that it provides a standardized and data-driven approach to problem-solving that can be applied in any industry or situation. By using DMAIC, organizations can identify and address the root causes of problems, improve processes, and achieve better outcomes, regardless of whether they are formally practicing Six Sigma or not.

The DMAIC Phases

Define phase.

In the Define phase, you collate a lot of information you already have available. You’ll:

- Understand the project, including its purpose and scope.

- Map the current process.

- Determine whether the process is a good candidate for DMAIC.

- Detail customer expectations.

- Estimate timelines and costs.

Should you use DMAIC?

Some projects aren’t suitable for this process. For example:

- It’s already very clear what the problem is and how to solve it.

- There’s no or little available data on the process to be improved.

- Managers and leaders do not support improvements to this process.

- The process does not directly impact key performance indicators.

- Measuring process improvements would be difficult or impossible.

Further information about the Define phase

For more information about the Define phase, the steps to go through, and the tools to use, see Define Phase (DMAIC) .

Measure Phase

You’ve mapped the existing process, understood the project, and decided that this is a good DMAIC candidate. You’ve listed customer expectations and estimated the times and costs involved.

Your next phase involves a lot of measurements. You need to have baseline figures to assess progress accurately in later phases.

During this phase, you will:

- Identify the data that you need to collect.

- Decide what measurements to use.

- Figure out what methods to use to collect your measurements.

- Determine the level of variation that you’ll be dealing with.

- Collect the data as per previous points.

Further information about the Measure phase

For more information about the Measure phase, the steps to go through, and the tools to use, see Measure Phase (DMAIC) .

Analyze Phase

In the Analyze phase, you work with the data that you collected in the Measure phase. You’ll:

- Identify defect causes.

- Analyze these to pinpoint the root cause.

Further information about the Analyze phase

For more information about the Analyze phase, the steps to go through, and the tools to use, see Analyze Phase (DMAIC) .

Improve Phase

You’ve identified the root cause of your issue in the Analyze phase. Now you need to come up with a solution. You’ll: