Change Password

Use of DREF technology for specific end uses in technical textiles - case study

Written by: C. R. Prayag Bipasha Maiti A.J. Sonagra

*Ahmedabad Textile Industry’s ResearchAssociation, Ahmedabad (ATIRA), **M/s. Zenith Fibers Ltd., Vadodara

Abstract: 12px;font-family:Georgia'> Polypropylene Staple Fiber (PPSF) is fast out pacing other synthetic fibers in terms of market growth and is finding new and varied enduses over old and traditional synthetic fibers. It is now being used in themanufacture of Drinking Water Filter Cartridges. ATIRA is producing the special type of technical textile, the PP yarn needed for this, using DREF Technology. In this paper, a case study, where the specifications of the PPSF fibersand the DREF yarns and their performance in drinking water filter cartridgeshas been given, will be discussed in detail. Filter yarns spun on DREF 2 machines have captured a leading position in the filter cartridge market. The annual worldwide requirement of such filter elements is in the region of several million units. The body of the filter consists of a perforated cylindrical support, which is wrapped by means of precision winding with a highly voluminous yarn (800-1500 tex). The thickness of this covering dictates the micron value of the filter, e.g., 0.5-200 micron. These filter elements are available mainly in the popular 250, 500, 750, and 1000 mm lengths. DREF Spinning Fehrer DREF 2 friction spinning is a versatile technology. It can be used for manufacturing everything from asbestos substitutes and secondary carpet backing yarns, to technical products such as cartridges for liquid filtration. 2

Fig 1: Fehrer DREF-2 Spinning Machine 3 This technology belongs to the open endgroup because the fiber strand (sliver) must be opened completely to individualizefibers and re-assembled to form a new strand (yarn). In DREF 2 spinning one ortwo carded slivers after leaving from the drafting arrangement are passed tothe main saw toothed opening roller. While the drafting arrangement createsonly a light drafting effect, the saw tooth roller opens the strand toindividual fibers. The separated fibers are lifted off the roller by a blowerand form cloud, descending towards two perforated drums. One suction stream perdrum draws the fibers into the convergent region. The newly arriving fiberscontact the rotating yarn and are thereby caught and twisted. This process is primarily suited for the production of coarser yarns and recycled yarns. The applications of DREF spun yarns are: Blankets for the hometex range and military uses, as well as for hotels, hospitals, camping plaids etc.; Secondary carpet backing for tufted carpets and filler yarns for carpet wefts; Filter cartridges for liquid filtration; Canvas for the military and civil sectors -Asbestos substitutes (e.g. heavy protective clothing and gloves, gaskets, packings, clutch- and brake linings, flame retardant fabrics etc.); Filler yarns for the cable, packaging, shoe and carpet industries; High-tenacity, core yarns for ropes, transport and conveyor belts; High tenacity fire resistant protective clothing ; Composites for the aviation, automotive and engineering industries etc. 1

At present, around 80 DREF 2 machines are spinning 30,000 t of yarns for liquid filtration. The main markets are Europe and the USA, where some 150 million filter cartridges are manufactured with DREF 2 yarns, a figure that represents 65-70% of global production. The leading US and European filter producers spin a wide range of DREF 2 PP-yarns at speeds of 160 - 180 m/min. A specialist manufacturer employs DREF products for over 20 types of cartridges that require compatibility with FDA foodstuffs legislation. The yarns employed generally consist of PP fibers in the 3.3 dtex, 40 mm range, which are highly resistant to micro-organisms and have a wide scope of chemical applications. 2 As per information available with us the demand of the DREF 2 PP yarns in India is about 800 tons per annum only for filter cartridges and it is likely to increase considerably in next one or two years. The fiber material of the yarns used is primarily selected with a view to the chemical properties and the temperature of the filtered substance. Manmade fibers account for the majority of applications, with cotton being prescribed mainly for environments where higher temperatures prevail.

Fig 2: DREF -2 Yarn Package and Wound Filter cartridges 4 PPSF has following unique properties: 1. Lowest specific gravity of 0.91 (provides excellent covering). 2. Negligible Moisture absorption (0.05). 3. Provides very warm feel (warmer than wool and acrylic). 4. Fabric containing PPSF wicks away moisture from skin to atmosphere due to the capillary action. 5. PPSF is resistant to many acids, alkalis and solvents. 6. PPSF is resistant to attack of mildew/moths/insects and a wide range of bacteria. 7. Not prone to static charge generation. 8. PPSF is dope- dyed in various shades/colours and there will not be any variation between fiber lots of the same shade. 9. Not subject to light degradation, if UV Stabilized. 10. Highly resilient fiber. 11. PPSF is available in round cross-section and also in Trilobal shape (for superior sparkle/luster.) 6 The details of the PP fibers used for the manufacture of the yarn for the filter cartridge at ATIRA and the quality parameters are given in the tables 1 to 3.

The most important characteristic of the filter element is its permeability expressed in µm. This indicates the minimum particle size (i.e. particle diameter) which will be eliminated to a minimum degree of 90%. Yarn package filter elements are used for separating particle sizes in the range of 0.5 to100 µm. Lowest possible price and high durability are the most important economic criteria. Moreover, lowest possible resistance to throughput (Δp) is desirable for every grade of permeability. Given the same type of yarn, permeability of the corresponding filter element directly correlates with the value of Δp. A higher Δp value means a lower µm grading of the filter element. The permeability of a yarn package filter element is in particular determined by the following parameters: -winding conditions (yarn path geometry, thickness of yarn layer, yarn tension during winding) -yarn parameters (yarn structure or spinning process, yarn twist factor, yarn count or rather yarn diameter, yarn uniformity) -Fiber material (in particular fiber fineness or rather fiber diameter) Given that all other parameters remain constant, finer fibers will increase the Δp values and at the same time, result in lower permeability. At the same time, filter elements of same permeability will feature lower resistance to throughput, i.e. lower Δp values if finer fibers are used instead of coarser ones. The influence of yarn twist factor on the resistance to throughput of filter elements is in the case of roving yarn. The lower the yarn twist factor, the higher the value, because the cavities between individual yarn strands are closer due to facilitated lateral compressibility of the yarn. The value often increases with the increase in yarn diameter in the range of yarn counts 800 to1500 tex. 8 font-family:Georgia;color:maroon'> Advantages of Friction-spun yarns over Flyer yarns (Rovings) for filter cartridges: -Better yarn regularity combined with high resistance. -Greater bulkiness of the yarn (20-40% more air volume) for better winding. Density compared to conventional filter cartridges. -Roving has to be highly twisted for winding into cones and this is not the case with Dref-2 yarn. With the result the porosity of roving gets adversely affected Less flow resistance than flyer yarns specially in tight packages -Improved dirt particle retention and up to twice the filter service life -The fiber structures are relatively random and subject to high degree of twist. The yarns offer great regularity and increased strength. -The round yarn cross-section ensures limited deformation under transverse load. -Considerable reduced yarn production costs (up to 50%) due to lower yarn mass requirement, lower preparation costs, lower spinning costs (as a result of higher output 15 to 20 times higher than with conventional production processes and high efficiency as well as bobbin weights up to 10 Kg.) and lower personnel expenses. -Knot-free, uniform quality of the yarns guarantees faultless filters up to a filter length of 200 cm. -Constant micron value in the filter due to regular yarn quality -Because of the layer construction of the yarn, its surface is twisted very loosely providing the hairiness necessary for good filtration (higher flow rate with the same filtration effect). -The universal use of all the fibers preferably processed for filters such as F.D.A. (Food and Drug Administration) bleached cotton, natural cotton, polypropylene, PP (F.D.A.), polyester, acrylic, modacrylic, polyamide and other special fibres. 7

font-family:Georgia;font-weight:normal'>The process of manufacturing the PP DREF 2 yarn upto drawframe is similar to that of normal synthetic fibers and no additional font-weight:normal'> spin finish is required to be used Efficiency of 80-90% is achievable at 180 m/min speed in DREF 2 machine. The waste level is 1-1.5% which is very negligible and is recyclable. One of the main problems related to practical working is that of fiber melting which leads to end breakage, lapping on combing roller and damage to the combing roller. This calls for optimization of combing roller speed and material feeding speed. So, it is very easy to convert PPSF into yarn by DREF 2 technology and the yarn is most suitable for filter cartridges which have a very good market potential in India and abroad. The usefulness of PP fiber in the manufacturing of technical yams has been also highlighted through this presentation and many such uses can be found for the fiber. There is a need to study the available technologies and find the appropriate one for the particular end-uses. References:

- New trends in machinery development for technical textiles - I-Express Textile-Nov,2005 ( www.expresstextile.com )

- http://www.fehrerag.com/fehrer/Artic08.htm

- www.wotol.com/machinery/fehrer-dref-2-ft-p13237/photo-1167129446945.jsp

- http://www.chinafrictionmaterial.com/eproduct-pp.htm

- http://www.pall.com/terms_38029.asp

- www.zenithfibres.com

- Manfred Gsteu, Tritz oberlehner-“DREF-Friction-spun yarns for filter cartridges”

- Mellind English, December 1990, pp.944-946

To read more articles on Textile , Industry , Technical Textile , Dyes & Chemicals , Machinery , Fashion , Apparel , Technology , Retail , Leather, Footwear & Jewellery , Software and General please visit http://articles.fibre2fashion.com To promote your company, product and services via promotional article, follow this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp

Leave your Comments

Related article.

Weekly technical textiles newsletter

Subscribe today and get the latest information on Technical textile

ABOUT TECHNICAL TEXTILES

- Privacy Policy

- Terms & Conditions

- Cookie Policy

Quick Links

- Advertise with us

- Get Listed with us

- Submit Press Release

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

A case study in the textile industry for the reduction of cost of quality

2019, Journal of Advances in Technology and Engineering Research

Related Papers

The Journal of Engineering Research [TJER]

Sheheryar Mohsin Qureshi

In developed countries, the application of the quality management system (QMS) is widely proven. However, in developing countries, like Pakistan, industries are not mature enough to understand and implement the system. The aim of this study is to examine the perception of quality, implementation of QMS and cost of quality (COQ) program in value-added garment sector, which is one of the major subsectors of textile industry in Pakistan. The methodology of the study is a questionnaire survey. The findings suggest that the majority of the respondent firms have well implemented quality management (QM) practices. Trend of results also depicts that most of the organizations wish to acquire ISO certification, which shows that the industrial processes are customer-centered thus striving to fulfil customer requirements. It can also be concluded that most of the organizations lack the COQ concept, its understanding and appropriate implementation.

Cogent Business & Management

RIYADH Y . AlSADA

This paper aims to determine the level of awareness and implementation of measuring CoQ in MIEs in Yemen. In contrast, this study was based on the traditional CoQ Prevention-Appraisal-Failure (PAF) model. Also, this paper proposes a suitable model for measuring CoQ in MIEs based on the research results. The Applied research focused on large companies where CoQ programs in the majority of companies operate as a subsystem of underlying management. Managers of large companies use indicators to control and evaluate performance for production quality. Still, they usually do not develop a separate framework for measuring and assessing CoQ. As a result, this research attempted to answer the question, Are Yemeni industrial companies interested in measuring, analyzing, and reporting CoQ items (prevention, appraisal, and failure costs) concerned in their industry? It also determines the extent these companies are interested in measuring, and analyzing hidden CoQ. According to this research findings, most major companies in Yemen are aware of and practice measuring CoQ. At the same time, the study showed that these companies are still not interested in measuring the hidden CoQ in their manufacturing.

Journal of Industrial Engineering and Management

Lamiaa Ayach

Purpose: The purpose of this study is to give an insight into the practices of Moroccan industrial companies in the area of managing quality costs. Furthermore, it analyses how the quality costing system (QCS) implementation and sophistication differentiate according to a number of variables (size, business market orientation, QMS Maturity...).Design/methodology/approach: In order to achieve this objective, a questionnaire survey has been conducted among a heterogeneous sample of 1000 industrial companies that are operating in the national territory yielding a response rate of 23.4%. This study uses exploratory and chi-square test in the process of answering the above-mentioned questions.Findings: The survey highlighted the limited use of quality costing practices among Moroccan industrial companies. Results indicated that 42.6% of surveyed companies are engaged in QCS while 63.4% of them do not. The primary barrier is the complexity of QCS implementation. Besides, findings pointed ...

Fahad Aunto

Rapid developments in international competition have obliged textile enterprises to take new approaches in order to gain a competitive advantage. The limits of acceptable quality levels for the enterprises have fallen back down to critical points due to the effects of liberal policies in international markets. Total Quality Management (TQM) keeps vital role in improving productivity, product quality and reduces manufacturing cost by reducing rework and scrape. TQM method has a great applicability in RMG sector. As RMG sector is the largest industrial sector of Bangladesh, Product Quality improvement can play a vital role in opening the doors of great opportunities for the country. To perform this study we take help of the tools of TQM such as Flow chart, Check sheet, Histogram, Pareto Chart, Scatter Diagram, Control Chart, Cause and effect diagram from various garment industries of Bangladesh to analyse collected data which were collected through observation method and it is found that a significant amount of rework and scrape per style, per month has minimized by applying this method. Implementing Total quality control applications are gaining in importance

Asadullah Bappi

This survey based study explored the implementation of lean manufacturing practices in textile industries of Pakistan. A total of 76 responses were received. The results of the study showed that the textile sector is at the beginning stage of lean implementation – more than half of the surveyed companies were in-transition to implement lean. The most important driver to implement lean was found to be organization's continuous improvement program followed by the drive to focus on customers, and desire to use best practices. The respondents perceived cost reduction to be the biggest benefit that can be achieved by implementing lean, followed by customer satisfaction, and improved delivery time. Among tools and techniques 5S, quality control circles, kaizen and SMED were used extensively. Manufacturing planning and control was not formally implemented. Human resource related factors were perceived to be crucial to effectively implement lean. Level of implementation was found to have a significant relationship with the size and the type of company and not with the age of the company. Lack of awareness to implement lean, company culture, lack of communication, and employee resistance were the main barriers faced by the sample companies during the implementation of lean.

journal of textile and apparel technology and management

Radha Kashyap

Timely and reliable measurement of manufacturing performance improvements after lean initiation in terms of Key Performance Indicators (KPI) not only enables the organization to evaluate the success of lean implementation, but, also to understand key areas for future improvements. Keeping the importance of using Key Performance Indicators (KPI), the present study was designed to comparatively assess the improvement in manufacturing performance among lean and non-lean initiated apparel units of National Capital Region (India) in terms of manufacturing key performance indicators-productivity, quality, work in progress and efficiency. The study was limited to 10 lean initiated and non-lean initiated apparel units each manufacturing the ladies garments in NCR. Apparel units in National Capital Region (NCR), India were selected using inclusion and exclusion criteria from the member list of Apparel Export Promotion Council, Gurgaon, India. A common full sleeve collar ladies top or shirt style was selected for this study. The Time Study Method was used to record the time taken to accomplish various operations involved in manufacturing of the selected common garment. Data was collected for all production days of the chosen design style. The result revealed that the lean initiated apparel export firms had higher operator productivity, total labor productivity and efficiency than the non-lean initiated units. Defect per hundred units and percentage defective in the lean initiated units were found significantly lower than the non-lean initiated units except for work in progress. Year of lean initiation was found to have significant difference in the performance of an apparel unit in the terms of efficiency and quality except for the productivity and work in progress. The research aimed to bring about awareness regarding positive impact of implementation of lean as the ultimate solution which could drive the global apparel industry towards achieving business excellence in today's heightened cut throat competition in the global apparel sector.

papers.ssrn.com

Dinesh Samarasinghe

IOSR Journals

MD SYDUZZAMAN , Dilruba Yeasmin

Textiles or clothing is one of the fundamental needs of human being. Today human being does not only meet this basic need, but also inclined to more fashion garments. They are introducing new and more fashion items on a regular basis to cope with the present era. That's why the RMG (Ready Made Garment) sector is running to its full swing with a huge variety of fashions. Bangladesh is one of the most promising garments manufacturing country in the present world now. It is now 2 nd largest textile and garments exporter in the world market. Textile and RMG sector is the core portion of this country's national economy as it earns nearly 81% foreign currencies from RMG sector [1]. It's now a crying need and todays demand to prepare a best RMG sector so that it can meet the growing demand more effectively. Besides, today's market is much more competitive and the only driving factor to sustain in this market is nothing but quality. So ensuring quality in RMG sector is the burning question now. To ensure this crucial factor (quality) there are so many tools and techniques have been emerged and implemented now-a-days. Among them the smartest and latest technique is Total Quality Management (TQM) Principles. By implementing TQM effectively, a production environment can be ensured which delivers quality products. In this research it will be pulled out, why TQM principles are vital and what the effects of implementing TQM in the apparel industry.

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

The Evolution and Impact of Technical Textiles

Exploring the evolution of industrial textiles.

Over the past few decades, industrial textiles have surged in prominence, with innovations reshaping sectors ranging from automotive to healthcare. While once relegated to mundane roles, textiles now form the backbone of critical safety systems, filtration processes, and structural reinforcements.

The Rise of Technical Textiles: A Silent Revolution

Industrial textiles, characterized by their specialized functionalities and performance-driven designs, stand as silent sentinels across diverse domains. Unlike conventional fabrics, these technical marvels are engineered to withstand extreme conditions, from chemical exposures to high mechanical stresses.

Unraveling the Mysteries of Technical Textile Manufacturing

Behind the veil of secrecy lies the intricate art of technical textile manufacturing. Proprietary processes and cutting-edge machinery weave together fibers of innovation to craft textiles tailored for specific applications. From nonwovens to woven fabrics, each variant demands meticulous attention to detail and bespoke production setups.

Applications of Technical Textiles: Navigating the Landscape

The applications of technical textiles span a myriad of industries, each harnessing their unique properties for transformative outcomes. From safeguarding lives to fortifying infrastructure, the versatility of technical textiles knows no bounds.

Explore our covered markets here: https://textilesinside.com/process-industry-markets/

Safeguarding Lives and Environments

Protective textiles form the frontline defense against environmental hazards, shielding both humans and ecosystems from harm. From flame-resistant fabrics to gas-proof membranes, these textiles epitomize innovation in safety and environmental protection.

Empowering Public Services

In the realm of public services, technical textiles serve as indispensable tools for defense, disaster relief, and law enforcement. Camouflage fabrics, ballistic shields, and NBC protective gear exemplify the fusion of functionality and durability in safeguarding public welfare.

Advancing Healthcare with Textile Innovations

The healthcare sector witnesses a revolution fueled by nonwoven textiles catering to diverse medical needs. Barrier fabrics, orthopedic textiles, and sanitary products underscore the pivotal role of technical textiles in promoting health and hygiene.

Revolutionizing Agriculture and Fisheries

In agriculture and fisheries, woven and knitted fabrics revolutionize cultivation practices and resource management. From shade fabrics for greenhouses to nets for enclosures, technical textiles foster sustainability and efficiency in food production.

Building the Future: Textiles in Construction

In construction , textiles provide indispensable solutions for insulation, roofing, and structural reinforcement. Whether in draining fabrics or shading screens, technical textiles uphold the highest standards of durability and performance.

Driving Innovation in Transportation

From land to sea and air, technical textiles form the backbone of modern transportation systems . Passenger safety, comfort, and performance are enhanced through the integration of textiles in automotive interiors, marine applications, and aerospace engineering.

Facilitating Packing, Transport, and Shipping

The logistics sector relies on technical textiles for a myriad of applications, from cargo nets to conveyor belts. These textiles ensure the safe and efficient movement of goods across diverse industries, from retail to defense.

Elevating Industrial Processes with Textile Filters

In industrial settings , textile filters play a pivotal role in purification and material processing. Whether in wet-filtration or dry-filtration applications, these high-tech textiles optimize efficiency and enhance product quality.

Exploring Miscellaneous Applications

Beyond traditional domains, technical textiles find niche applications in diverse fields, from cinema screens to sports equipment. Their versatility and adaptability continue to inspire innovation across industries.

Pioneering Geotextiles: Shaping the Future of Infrastructure

Geotextiles emerge as a cornerstone of modern infrastructure projects, offering solutions for soil stabilization, erosion control, and water management. Through ongoing research and education, textile manufacturers propel the evolution of geotechnical engineering.

Embracing the Future of Technical Textiles

As industries evolve and challenges mount, the role of technical textiles grows ever more pivotal. Through innovation, collaboration, and a relentless pursuit of excellence, textile professionals stand poised to shape a future where technical textiles reign supreme.

Share this article

This article is published by

Groundsailer Media BV

More from groundsailer media bv.

- 3 April 2024

- 19 March 2024

- 23 January 2024

- 19 January 2024

Related Articles

Subscribe to our E-newsletters

Get the extensive coverage for technical textile professionals who buy, maintain, manage or operate equipment, delivered to your inbox (it’s free!).

By signing up for our list, you agree to our Terms & Conditions . We deliver two E-Newsletters every week, the Weekly E-Update (delivered every Tuesday) with general updates from the industry, and one Market Focus / E-Product Newsletter (delivered every Thursday) that is focused on a particular market or technology.

Flexible Connections Ltd

Arville Textiles Limited

Contitech ag.

Since 2020, we have been providing professionals with the latest innovations, case studies, and a comprehensive equipment guide for industrial textile applications.

Site navigation

Upcoming events.

- Hightex 2024

- 04 Jun, 2024

- Achema 2024

- 10 Jun, 2024

- Febratex 2024

- 20 Aug, 2024

Advertise with us

© TextilesInside 2024

- Open access

- Published: 13 January 2017

Sustainable and ethical manufacturing: a case study from handloom industry

- D. G. K. Dissanayake 1 ,

- Srimala Perera 2 &

- Thushari Wanniarachchi 1

Textiles and Clothing Sustainability volume 3 , Article number: 2 ( 2017 ) Cite this article

44k Accesses

16 Citations

2 Altmetric

Metrics details

Global fashion industry has bitterly evidenced the social and environmental implications associated with fast production cycles, overuse of resources, waste generation, environmental pollution and unethical labour conditions. Growing consumer awareness regarding social and environmental impacts of fashion products has led to create a new marketplace for sustainable and ethical products. This paper highlights craft practice as one of the potential avenues for achieving sustainability within the fashion industry. Through a case study drawn from handloom industry, this paper explores a manufacturing approach that is committed to fair-trade principles and designed to prevent waste. We argue that this study reveals a business model that could positively contribute towards generating employment opportunities and sustainable household income for the rural community. We conclude the paper by highlighting that this type of a fair trade and environmentally conscious manufacturing process could address the three pillars of sustainability: social, economic and environment. Findings of the study invite manufacturers to revisit and redesign current fashion production systems, especially when waste and labour issues are hindering the sustainability.

Sustainability could be explained in many different ways. Yet, for the fashion industry, sustainability means the ‘environmental protection, social justice, economic fairness and cultural validity’ (Parker, 2011 , p4). Globalization and technological advancements have made a dramatic change in production and consumption patterns of the world’s fashion. This global industry started to pose many challenges for sustainability efforts as fashion has become a throw-away commodity, and rapid phase production of short-lived products have become a normality. Cultural flavour of fashion has diminished as fashion became globalized and influenced by global trends. Vast availability of cheap, low-quality clothing allows overconsumption and premature disposal of fashion products (Niinimäki, 2011 ).

Textile and fashion industry is well known for exploitation of resources and unsustainable manufacturing practices, where environmental and social losses are often ignored (Beard 2008 ; Walker, 2007 ). However, the growing awareness among consumers regarding the social and environmental impacts of fashion consumption has made a significant influence on the purchasing decisions towards ethical and sustainable fashion. Possible integration of craft and contemporary fashion has gained much attention in this context, mainly due to its potential contribution towards more sustainable futures (Ferraro et al., 2011 ). Hur and Beverley ( 2013 ) explored the role of craft in promoting sustainable fashion, in terms of both production and consumption. Cox and Bebbington ( 2015 ) insisted that craft practice and social sustainability share common aspirations, and if craft would support to meet sustainable development principles, it may help craft products to access new markets. In this regard, it is commendable that a practical approach has been taken by the Ethical Fashion Initiative, in which there is an attempt being made to connect marginalized craftspeople from developing world to the international fashion industry (International Trade Centre, 2016 ). It is therefore evident that the craft practices in fashion could address environment as well as other broader dimensions of sustainability, as it tends to promote the well-being of the local producers and craft communities towards a sustainable lifestyle.

Globally, Sri Lanka is recognized not only as an export-oriented fashion manufacturing base but also as a home for a rich fashion craft industry. Sri Lankan fashion craft industry, which comprises mainly of handloom, batik, beeralu and embroidery, is one of the main income generator for rural communities and differently able people. With the developmental needs of the country in the post-war era, fashion craft industry is recognized as one of the most important industries for poverty alleviation, employment generation, enhancement of rural entrepreneurship and the development of new business opportunities (Export Development Board, 2013 ). Gradual development of local fashion craft industry not only generates economy but also promotes sustainable production and slow consumption. Nevertheless, an increasing global demand for environmentally sustainable products holds a greater potential for expansion of the global market for craft products. However, only a limited research has been carried out to highlight the importance of fashion craft industry in the context sustainable and ethical fashion movements.

Sri Lankan handloom industry

Handloom is a traditional weaving craft, practiced by generations of artisans to make attractive textile designs. Sri Lankan handloom industry is a highly labour- incentive and a decentralized sector of which the most of the manufacturing units are located in rural areas (Export Development Board 2013 ). It is also an environmentally friendly, low energy-driven sector where fair-trade manufacturing practices are appreciated and encouraged (Dhingra and Dhingra, 2012 ). In Sri Lanka, the handloom industry maintains a significant demand since its inception, due to its cultural artefacts, heritage and design capabilities. Sri Lankan handloom textile industry reached its peak in 1970s and experienced a decline after 1978, with the onset of the open economic policies and the growth of export-oriented apparel industry sector in Sri Lanka (Gomas, 2000 ). However, with the raising developmental needs of the country in the post-war era, handloom industry was repositioned as one of the most important industries to launch business opportunities for the development of local economy. As handloom textiles and handcrafted products have rapidly become major lifestyle statements for both national and international consumers, this industry now carries a significant potential for expansion, employment generation with lucrative export earning opportunities.

Further, Sri Lankan handloom textiles are highly recognized both locally and internationally not only for its innovative and modern design trends entwined with traditional craftsmanship but also for its premium quality. The products are often offered to global niche markets where handcrafted items of high value are preferred. In Sri Lanka, it is estimated that around 6,500 handlooms are in operation, providing around 10,000 direct employment opportunities (Ministry of Industry and Commerce, 2012 ). Seven hundred seventy-one production centres are owned by provisional councils whereas 962 units scattered around the country are privately owned (Export Development Board, 2013 ). The industry serves both local and international markets with a wide range of product categories such as ready-made garments, soft toys, bed linen, table linen and curtain. Export markets for handloom products include Italy, Germany, Australia, France, Spain, Japan, Korea, Sweden, USA, Vietnam, Lebanon, Thailand, UK, Norway, Netherlands, etc. (Ministry of Industry and Commerce, 2012 ). In the year 2012, the total value of exports brought by the handloom sector was estimated as USD 870,000.

Globally, the green movement and fair labour movement are steadily getting momentum. Consumers are increasingly demanding products that are ethically made and environmentally safe (Lewis and Potter, 2011 ; OECD, 2008 ). While the modern consumers are concerned about the social and the environmental impact of the product they purchase, they incessantly criticize traditional manufacturing processes with highly pressurized production environments and poor labour conditions (Koszewzka, 2011 ). This shift in consumers’ mind has led to a change in buying habits towards environmentally sustainable and ethical products (Shaw et al., 2006 ).

Fair trade represents an ethical approach to product manufacturing. This is also an important approach to alleviate poverty in the global south while contributing to build a socially and environmentally sustainable international trade (Taylor et al., 2005 ; Raynolds et al., 2004 ; Shreck, 2002 ). Fair trade aims to support farmers and craftsmen who are socially and economically marginalized. Community improvement, women empowerment and mitigation of environmental impact of the production process are some of the key aspects of fair trade (Andorfer and Liebe, 2015 ; Bassett, 2010 ). Access to fair-trade business models not only guarantee higher income levels but also promote collaboration and positive cultural bond among associates. Moreover, people who engage in fair-trade supply chain add value to their own culture, their identity, environment and also to the product (Belgian Development Agency 2012 ). One essential feature of fair trade is to support local community to organize and operate collectively, which enhances trustworthiness among local communities. The World Fair Trade Organization (WFTO) represents a global network of fair traders who are committed to the WFTO fair-trade standards. This network may include manufacturers and retailers who are driven by fair-trade values. They signed up to follow a set of compliance criteria based on ten fair-trade principles that focus on fair prices, good working conditions and minimizing environmental impacts (World Fair Trade Organization, 2014 ).

One of the key focuses of fair-trade practice is to minimize environmental impact of production. Application of sustainable production methods and reduction of waste generation are among key priorities. Waste is a growing problem associated with environmental and social impacts, which remain unresolved to date (Sinha et al. 2016 ). Waste can also be an indicator of an inefficient process (Pongrácz, 2009 ) which ultimately makes monetary lost in two stages: first when raw materials are purchased and then at the time when waste materials are discarded. Moreover, waste, when dumped in open areas, causes several environmental and health issues. It is essential to decouple the waste growth from the economic growth to minimize environmental impact and also to conserve resources. In response to the waste issue, a zero-waste approach has been committed by many industries. This is based on the central notion that prevention of waste is more desirable than treatment of waste (Greyson 2007 ).

According to Zero Waste International Alliance ( 2015 ), zero-waste strategy aims at designing products and processes to avoid waste, i.e. eliminations of all discharges to land, and conservation of resources. Zero-waste system reuses discarded materials to make new products. This process reduces the exploitation of natural resources, avoids pollution, and saves the environment. Textile and apparel industry uses tremendous amount of materials and energy resources and produces a massive quantity of waste, leaving a huge negative environmental impact. Therefore, achieving zero material waste is one of the greatest challenges of the apparel manufacturing industry. Unfortunately, zero waste, potentially a preventive approach, is often misunderstood as unrealistic and impossible target to achieve within the boundary of today’s economic conditions (Greyson 2007 ). However, if zero-waste system is properly implemented, apparel manufacturing industry could possibly convert waste into something useful and economical. Rissanen and McQuillan ( 2016 ) highlighted that the concept of zero waste in fashion design addresses the inefficiency in fabric use and provides opportunities to explore new forms of creation.

Handloom industry could be a powerful sector for developing local economy, promoting ethical trade and sustainable communities in Sri Lanka. However, there is a little empirical research done to date regarding the actual benefits, especially when the industry is engaged in an environmentally conscious production and ethical trade. This paper draws a case study from Sri Lankan handloom textile industry to illustrate an enviornmrentally and ethically responsible manufacturing approach.

A case study approach was employed to investigate the sustainable and ethical manufacturing practices of a handloom textile manufacturing company based in Sri Lanka. Case study is considered as the preferred method when holistic, in-depth investigation is needed, as this method allows the researcher to closely examine the data within a specific content and investigate the real-life phenomenon (Yin, 2003 ). An in-depth examination of a single case has been used in this research, because the main purpose of this study was to gain a deep understanding of a specific theme of application and share the best practices. Single case allows better explanation of an application of a theory or principle. As Siggelkow ( 2007 ) emphasized, single case can be a very powerful example, if it represents a rare phenomenon. Generalization in this case could mean the application of finding to another single case, but not for the whole population (Mariotto et al., 2014 ). X Ltd has been selected as the case because it is the only fair-trade guaranteed textile handloom company in Sri Lanka, which allows generation of new insights that other textile handloom companies in the country have not yet been able to generate.

For this study, data were collected using semi-structured interviews and field observations. Interviews were conducted with the Factory Manager, Human Resource Manager and the Business Manager of the company. Sustainable manufacturing process and the adherence to fair-trade principles were investigated in detail and verified by using two consecutive field visits.

X Ltd started in 1991 with 15 women employees, gradually developed into a social enterprise that empowers women entrepreneurs, which then led to a buildup of sustainable communities. It is a design-led handloom textile manufacturing company that has gained a solid reputation for supplying 100% cotton, handmade products of superior quality and innovative designs. As one of the dominant suppliers of quality handloom products in Sri Lanka, X Ltd gained a significant market share for a variety of handloom textile-based products such as handloom clothing, hand-crafted soft toys, household linen and also various types of accessories. The company also captures a place in the global market as a supplier of sustainable, handcrafted products. Approximately 85% of the company exports are sent to European countries such as Germany, UK, Netherlands, France and Italy. Further, X Ltd also caters to other export markets such as Australia, USA, Japan, India, Korea, Thailand, Norway, Sweden, China and Maldives. Products are showcased in some of the world renowned trade exhibitions such as the Frankfurt Gift Fair.

X Ltd owns four major production facilities located in the rural areas of the country. Main production facility comprises of a dye house, a weaving centre, a cutting room, an apparel manufacturing section and also toys and accessories manufacturing section. Additionally, there are various decentralized weaving centres or home-based weavers linked to the four major production facilities. Main production facility supports not only decentralized weaving centres but also home-based craftsmanship where discarded handloom textiles are converted into useful by-products. The company also owns retail shops in various cities in Sri Lanka to sell their products locally.

Case study reveals that the manufacturing practice of X Ltd represents some of the key elements of sustainable fashion. Their products are manufactured with an environmental and social responsibility in mind. Significant time is spent to develop unique designs, leaving space for creativity, with premium quality and longevity. Handloom fashion clothing is designed to be trans-seasonal and caters essentially to a high-end, niche market. Unique fashion designs give the consumers a personalized feeling and satisfaction of wearing a quality, handcrafted product.

X Ltd is committed to fair-trade principles with a special focus on community-centred sustainability through empowering poor, particularly women and differently able people. X Ltd is a member of WFTO since 2012 and committed to follow ten fair-trade principles, as described in the “ Fair-trade practice ” section. Moreover, manufacturing process has been developed to achieve ‘zero material waste’, which is further explained in the “ Zero-waste manufacturing ” section.

Fair-trade practice

X Ltd subscribes and maintains ten fair-trade standards prescribed by WFTO, as follows:

Creating opportunities for economically disadvantaged producers

This principle focuses on poverty alleviation through trade forms by providing opportunities for marginalized small-scale producers. X Ltd assists people who demonstrate weaving and craft skills yet struggle to find initial capital to purchase raw materials or unable to access a suitable market to sell their products at a reasonable price. X Ltd provides those people with various advocacy schemes by;

Providing raw materials, product designs and any other resources required to run a home-based production.

Providing residential training regarding product designs, expected quality levels and required skills for them to develop independent production facilities.

Appreciating and promoting their design ideas.

Committing to purchase their products at a fair price.

Moreover, company works with the local communities and encourages them to create working groups. They are provided with adequate resources such as raw materials and credit facilities to purchase machinery to start community-based manufacturing centres (for weaving or creating by-products from material waste). X Ltd is committed to buy their products by paying a fair price, which, in return, helps the community to be employed and raise their living standards.

Transparency and accountability

This principle highlights the requirement to be transparent in managing all aspects of the business. By adhering to this principle, X Ltd keeps records of all of its transactions and maintains evidence whenever possible. For instance, records are maintained for employee training, skill development programmes, welfare facilities and payments to third parties. Employees’ register is regularly updated for both in-house workers and those who work remotely. Company also maintains an event calendar for annual training programmes and welfare activities which are financed by the annual budget. An annual report is prepared including all the necessary information as per WFTO standards and presented in regular audits. In order to ensure the transparency and accountability, X Ltd provides updates to WFTO at regular basis regarding their events and actions.

Fair trading practices

X Ltd works cooperatively with its employees and maintains long-term relationships, especially with the employees who work remotely. Operational relationships are based on mutual trust, respect and effective communication. There is a guaranteed purchase of products manufactured in home-based or community centres. In case of quality issues or any other manufacturing defects, employees are retrained and the confidence is rebuilt, as the whole idea of fair-trade practice is to give these economically disadvantaged people a helping hand to raise their livelihood. This concept of trading goes beyond the commercial aspects of a business as an employer, and workers are continuously committed to develop and maintain fair trading practices. Moreover, if anyone in the surrounding community is interested in joining the business as a sub-contractor or an individual weaver, X Ltd provides necessary resources to start up the business such as initial training, loan facilities, raw materials and machineries. For those who are willing to be employed in the main production facility, several welfare facilities are provided by the company in order to create better working conditions. For example, bicycles are donated for the people who need to travel a long distance, and child day-care centres are operated within the premises so that parents could keep the children in their vicinity in the day care centre while working in the weaving centre. Women are encouraged to enrol their child to the day care centre, and they are allowed to visit their children during the lunch break, etc.

Payment of a fair price

A fair wage is paid for the employees who work in the production facilities, and the opportunity is given to earn incentives for any extra units produced beyond the target level. For home-based workers or decentralized working groups, raw materials are provided and a guaranteed minimum price is paid for each of the unit produced. X Ltd has an open policy to disclose the cost breakdown of any product manufactured, which facilitates workers to ensure that they are getting a fair price. X Ltd also allocates a percentage of the annual profit for employees’ training, development and welfare facilities.

Ensuring no child labour or forced labour

Recruitment of employees and payment structures are based on the national labour law. People below 18 years of age are not recruited, and child labour is strictly prohibited, even in a home-based working environment. Production efficiency target is set for 50%, and the employees are not forced to exceed the target. However, an incentive is paid for the individuals who exceed the daily target with the expected quality. Decentralized or home-based workers experience a very flexible working environment, and their targets are considerably lower than the factory targets, yet it is agreed upon to complete a specified amount of pieces within a given period of time. Individual circumstances are considered, and manageable targets are set for people who have personal commitments, as fair-trade practice always promotes ethical working conditions.

Commitment to non-discrimination, gender equity, women’s economic empowerment and freedom of association

X Ltd does not discriminate its employees based on their gender, disability, religion or race. Both male and female workers are employed; however, female employees represent the majority of the workforce (95% are female workers). Nevertheless, the management represents 50% of male and 50% of female workers. There are also differently able employees working in production facilities and in home-based centres. They are given special attention and provided with achievable production targets. Particularly, women employees are empowered and encouraged to take the leadership of the business. The nature of the business facilitates empowering women as most of weavers or craft workers are women who may ultimately become entrepreneurs or the leaders in weaving or craft centres.

While there are no restrictions to join trade unions, company has developed an internal system to listen and resolve the issues or concerns of the employees. Small groups comprising of few employees and management representatives are formed for the purpose of providing a platform to discuss any concerns or issues of employees. Those discussions usually lead to identify problems and provide appropriate solutions. Management representatives of each group forward the discussion minutes to the ‘think tank’ team which is comprised of senior managers. They evaluate the issues and forward the recommendations to the board of directors for further action. The company has been able to resolve several employee issues through this initiative, which can be recognized not only as a friendly approach to deal with employees’ concerns but also as a platform where several ideas for business improvement would emerge.

Ensuring good working conditions

X Ltd is committed to provide safe and healthy working environment for all of its employees as per the guidelines provided in the national labour law. Employees are educated regarding health and safety requirements through regular awareness programmes organized by the company. Frequent audits are conducted to ensure safety working conditions, both in production facilities and decentralized working centres.

Providing capacity building

X Ltd supports to develop skills and capabilities of the employees, from home-based weaver to the top management. New employees receive 6 months training that focuses on process awareness and skill development. Management staff undergoes an assignment-based training in each section of the company, which in turn would help to improve their knowledge regarding the working process of each of the sections and the skill/knowledge required to fulfil each of the tasks. Moreover, company-sponsored education or training programmes (skill development, quality, leadership, etc.) are provided to the employees, including home-based workers, in order to upgrade their knowledge and skills. Progress of each employee is evaluated through an employee appraisal system, which is held once in every 3 months, and the employees are further developed using follow-up action plan.

Promoting fair trade

X Ltd promotes the concept of fair trade both locally and internationally through awareness programmes, displaying fair-trade logo or a label and taking part in various fair-trade fares. In several occasions, company management has been invited to give promotional speeches in world fair-trade conferences.

Respect for the environment

While handloom industry is recognized as an environmentally sustainable industry due to its low energy and resources used, X Ltd has taken further sustainable initiatives to improve its environmental performance. Raw cotton is imported from India and dyed in a company-owned dye house by using standard German dyes, which are less toxic. Waste water from the dye house is treated and released to agricultural fields, and the dye sludge is sent to be reused in the cement industry. The production process focuses on achieving zero material waste, as explained in the “ Zero-waste manufacturing ” section.

Zero-waste manufacturing

X Ltd takes a responsible approach to avoid landfill or incineration of textile waste and to promote reuse of waste 100% to create various by-products. ‘Zero material waste’ is the goal of this approach where waste fabrics from one manufacturing process are used as input materials to create another product. Fabrics are woven entirely by using handloom machines, and the output could be either a handloom saree or a fabric. If the product is a saree, it is woven for the required dimensions without generating any waste material. Other handloom fabrics are mainly used to produce handloom apparel, household linen, accessories and soft toys.

Handloom apparel products are limited in designs and quantities. As the fabrics are colourful and attractive, designs are meant to be simple, yet those garments are suitable for many occasions due to their premium quality and rich appearance. Waste fabrics generated from the apparel manufacturing process are used to create diverse range of by-products, as shown in Fig. 1 . These waste fabrics are used very systematically and creatively and selected carefully for each of the by-product based on the size of the waste material. For example, the largest pieces of fabrics are used to create products such as bed runners, pillow cases or tablecloths. Next size set of waste fabrics is used to create products such as table mats, soft toys and laptop covers. Subsequently, remaining sizes are used to manufacture purses, patchwork products (table mats, appliqués for cushion covers, small soft toys, etc.). The smallest set of waste fabrics are used to manufacture accessories such as hair bands, necklaces, key tags and home decorations. X Ltd connects with a number of local craft workers and provides them with waste materials to manufacture those by-products.

Product range: achieving product diversity through zero material waste approach

As the company policy is to divert all wastes from landfills, even a small piece of fabric is not wasted, rather reused to make something useful and marketable. Tiny pieces of fabric off-cuts are utilized to produce thin layers of sheets as shown in Fig. 2 . The production process of creating such sheets includes grinding small fabric pieces and mixing them with glue, squeezing using rollers and pasting back into fabric to make colourful, thin layers of sheets. Those sheets are exported to Sweden to be used for packaging purposes or craft work at nursery schools.

Craft sheets created from waste fabrics

Not only waste fabrics but also waste threads are reused to make very creative lamp shades in various shapes and attractive colours, as shown in Fig. 3 . Premium quality is integrated into all products that target high-end consumer markets, both locally and internationally.

Lamp shades created from waste threadsᅟ

Environmental and social challenges faced by the global textile and fashion industry should be dealt with the development of a range of solutions. As consumers increasingly respect the environment and ethical practices, sustainable and fair trade certified fashion products are in demand. Fair trade is a recognized strategy for rural development in the Global South. While traditional welfare approaches have failed to address the labour issues associated with the international trade, fair-trade movement has remarkably bridged the Northern consumers’ interest on ethical purchasing with the Southern producers’ efforts of gaining fair returns. This type of a concept is extremely important for uplifting living standards of the rural communities and the fashion consumers who are longing for ethical and green products.

This case study provides a good example of the application of fair-trade principles in the textile handloom industry. Here, it is evident that there is a definite potential of this practice to establish a new direction in environmentally and socially responsible textile and fashion products. Fair-trade principle is a globally recognized approach for fair terms of trade. Community benefits from the fair trade are easily identified through the study. The key benefits would be the increase of employment opportunities for the people who require paid work, empowering individuals, capacity building, improving the quality of life and strengthening the social cohesion within a community.

It is well understood that the 30 years of civil war in Sri Lanka destroyed the infrastructure, injured the country’s productive forces, weakened the moderate influential people and resulted in identity withdrawal. Furthermore, during these extended periods of war, local women often suffered directly or indirectly as their husbands and adult children took up arms. Textile handloom manufacturers in North and North East regions were heavily affected by this situation, and thus, the industry experienced a decline. In attempting to redevelop these communities in the post-war era, bringing together populations and the use of stabilizing projects cannot be fully achieved using the traditional economic models which are merely driven by profits. Alternatively, fair and sustainable trade could provide a valid and beneficial approach in rebuilding communities. Fair-trade approach could open up opportunities for local producers in the war-affected areas to earn sustainable income and improve future prospects for their communities. Therefore, it is vital to invest on restoring this industry in war-affected regions and assist them to align the business with fair-trade principles. This type of an initiative would help to achieve a rapid improvement on the well-being of the local populations and enhance the pacification of relationship with former rivals. In this regard, this case study provides a feasible trading approach that could be adopted to rebuild the textile handloom industry in the war-affected regions of Sri Lanka.

Home-based or community-centred working models evident through this study provide a viable employment option for rural women who want to contribute to family earnings but unable to travel long distances due to family commitments. Nevertheless, many rural women in Sri Lanka tend to go abroad as domestic workers to raise their living standard, which leads to several social issues including the safety and protection of the children and the unrest among family members. A home-based or a village-based employment opportunity could resolve many of those issues and would provide a flexible working environment for women to balance their work life and family life. It is therefore evident that the fair-trade approach could become a potential solution for the issues of poverty and well-being of the rural community of Sri Lanka.

Successful application of the concept of ‘zero material waste’ in X Ltd boldly confronts the common understanding of ‘achieving a waste free manufacturing environment is unrealistic’. Moreover, this study proves that zero-waste approach carries obvious potential for positive economic growth. Indeed, product diversification of X Ltd is achieved through the zero material waste approach, in which waste materials are used as resources to design various by-products that cater to different market segments. For instance, soft toys, fashion accessories and patchwork products are designed using waste materials, and they can be introduced to a different market to that of their core products. While most of those products have already gained access in the global market, rapid increase in the global demand for sustainable and fair-trade products would open up new trade avenues.

Achieving business success whilst respecting the three pillars of sustainability (economic, social and environmental) is still a struggle to many businesses. In this context, this study demonstrates a potentially viable business model that interlinks the environment, human well-being and economic benefits for the success of a business. Key features of this model could be highlighted as community-centred production, guaranteed minimum price leading to a stable income for workers, more accessibility to export markets through fair-trade labelling, enhancement of producer self-confidence, reduction of disputes, resistance to conflicts and respect for the environment.

Recommendation for future research

Sri Lankan craft sector is still under explored to understand its potential to reap economic benefits. Furthermore, conventional economic data always underestimates the capacity of this sector and its potential for the development of microeconomies. Many small-scale producers seem to be often ignored, and therefore, an accurate representation of the economic, social and cultural impact of this industry is lacking. Hence, it is recommended to conduct a detail study of the handloom sector to discover the current status and also to update statistical data of the sector that would support further research and analysis.

This case study demonstrated the application of fair-trade principles using a single case. It is recommended to conduct similar type of studies with other handloom manufacturing organizations in Sri Lanka to enable comparative analysis and verification of the impacts of fair trading. It is also worthwhile to investigate the possibility of applying fair-trade principles to other community-based craft industries in Sri Lanka, in order to make those industries economically, socially and environmentally sustainable in the long run. Moreover, fair-trade impact assessment on craftsmen in enhancing capacities and improving their quality of life needs to be explored through direct dialogues with them.

Conclusions

The study attempts to explore the possible connection between craft practice and sustainable development. This research demonstrates the successful application of fair-trade principles in developing sustainable trades and communities. It also suggest a sustainable business approach that could possibly be adopted by other textile handloom manufacturers and craft businesses. If this model was to be expanded significantly with the inclusion of communities affected by war, it would positively influence local economy and also the society by alleviating poverty, rebuilding collaborative relationships among different ethnic groups and safeguarding the cultural identity of Sri Lanka.

Sustainability is soon changing from an option to a necessity. As the global demand for sustainable and ethical products surge, application of sustainable and ethical aspects in developing textile handloom products would help to improve the recognition and also the market share in the local and global markets. It is therefore recommended to explore other community-based craft practices in Sri Lanka and investigate the possibility of turning those to profitable businesses by aligning them with sustainable development and fair-trade principles.

This research is limited to a single case study and cannot be generalized to a wider population. However, this study invites other craft practitioners to revisit their manufacturing processes and investigate the possible application of sustainable and fair-trade principles into their businesses to harness the social and economic development.

Andorfer, V. A., & Liebe, U. (2015). Do information, price, or morals influence ethical consumption? A natural field experiment and customer survey on the purchase of Fair Trade coffee. Social Science Research, 52 (2015), 330–350. doi: 10.1016/j.ssresearch.2015.02.007 .

Article Google Scholar

Bassett, T. J. (2010). Slim pickings: fairtrade cotton in West Africa. Geoforum, 41 (2010), 44–55. doi: 10.1016/j.geoforum.2009.03.002 .

Beard, N. D. (2008). The branding of ethical fashion and the consumer: a luxury niche or mass-market reality? Fashion Theory, 12 (4), 447–468. doi: 10.2752/175174108X346931 .

Belgian Development Agency (2012). Fair Trade in War Zones. http://www.befair.be/en/publication/thematic-brochures/fair-trade-war-zones . Accessed 20 Mar 2016.

International trade Centre (2016) Ethical Fashion Initiative. http://ethicalfashioninitiative.org/ethical-manufacturing/ . Accessed 10 Oct 2016.

Cox, E, and Bebbington, J. (2015). Craft and sustainable development: an investigation. https://www.st-andrews.ac.uk/media/sasi/documents/Craft%20and%20Sustainable%20Development.pdf . Accessed 16 Oct 2016.

Dhingra, V., & Dhingra, M. (2012). Factors affecting quality of work life of handicraft workers—a study of handicraft units in and around Moradabad. New York Science Journal, 5 (10), 105–113.

Google Scholar

Export Development Board (2013). Industry capability report: Sri Lankan handloom sector. Available at: http://www.srilankabusiness.com/pdf/incapreporthandloom.pdf . Accessed 24 Apr 2016

Ferraro, E, White, R, Cox, E, Bebbington, J, and Wilson, S. (2011). Craft and sustainable development: reflections on Scottish craft and pathways to sustainability. Craft + Design Enquiry , 3,1–26.

Gomas, S. (2000). Handloom weavers shuttle into poverty. Asia Times. http://www.atimes.com/ind-pak/BD08Df02.html . Accessed 02 May 2016

Greyson, J. (2007). An economic instrument for zero waste, economic growth and sustainability. Journal of Cleaner Production, 15 (13-14), 1382–1390. doi: 10.1016/j.jclepro.2006.07.019 .

Hur, ES, and Beverley, KJ. (2013) The role of craft in a co-design system for sustainable fashion. Making Futures. http://eprints.whiterose.ac.uk/81260/ . Accessed 15 Oct 2016.

Koszewzka, M. (2011). Social and eco-labelling of textile & clothing goods as means of communication and product differentiation. FIBRES & TEXTILES in Eastern Europe, 19 (4), 20–26.

Lewis, T., & Potter, E. (Eds.). (2011). Ethical consumption: a critical introduction . New York, NY: Routledge.

Mariotto, F. L., Zanni, P. P., & DE Moraes, G. H. S. M. (2014). What is the use of a single-case study in management research? Revista de Administração de Empresas, 54 (4), 358–369. doi: 10.1590/S0034-759020140402 .

Ministry of Industry and Commerce. (2012). Report of the task force for a sustainable development of the handloom industry in Sri Lanka. http://www.industry.gov.lk/web/images/pdf/hand%20loom.pdf . Accessed18 Aug 2015

Niinimäki, K. (2011). From disposable to sustainable: the complex interplay between design and consumption of textiles & clothing . Helsinki: Aalto university publishing.

OECD. (2008). Promoting sustainable consumption: good practices in OECD countries. http://www.oecd.org/greengrowth/40317373.pdf . Accessed 06 Aug 2016

Parker, E. (2011). Steps towards sustainability in fashion: snapshot Bangladesh. http://ualresearchonline.arts.ac.uk/2754/ . Accessed 22 Mar 2015

Pongrácz, E. (2009). Through waste prevention towards corporate sustainability: analysis of the concept of waste and a review of attitudes towards waste prevention. Sustainable Development, 1 , 92–101. doi: 10.1002/sd.402 .

Raynolds, L., Murray, D., & Taylor, P. L. (2004). Fair trade coffee: building producer capacity via global networks. Journal of International Development, 16 , 1109–1121. doi: 10.1002/jid.1136 .

Rissanen, T. and McQuillan, H. (2016) Zero waste fashion design . UK: Bloomsbury Publishing Plc.

Shaw, D., Shui, E., Hogg, G., Wilson, E., & Hassan, L. (2006). Fashion victim?: the impact of sweatshop concerns on clothing choice. Journal of Strategic Marketing, 14 (4), 427–440. doi: 10.1080/09652540600956426 .

Shreck, A. (2002). Just bananas? Fair trade banana production in the Diploma Republic. International Journal of Sociology of Agriculture and Food, 10 (2), 13–23.

Siggelkow, N. (2007). Persuasion with case studies. Academy of Management Journal, 50 (1), 20–24.

Sinha, P, Muthu, SS, and Dissanayake, G. (2016) Remanufactured fashion . Springer Science + Business Media Singapore.

Taylor, P. L., Murray, D. L., & Reynolds, L. T. (2005). Keeping trade fair: governance challenges in the fair trade coffee initiative. Sustainable Development, 13 (3), 199–208. doi: 10.1002/sd.278 .

Walker, S. (2007). Sustainable by design explorations in theory and practice . London: Earthscan.

World Fair Trade Organization (2014). Ten principles of fair trade. http://www.wfto.com/fair-trade/10-principles-fair-trade . Accessed 28 Jan 2015

Yin, R. K. (2003). Case study research: design and methods . Newbury Park: Sage.

Zero Waste International Alliance (2015). ZW definition. http://zwia.org/standards/zw-definition/ . Accessed 07 Mar 2016.

Download references

Authors’ contributions

DGK designed the research and methods. DGK, SP and TW conducted the field visits and collected the data. DGK and SP drafted the manuscript. TW provided the technical help. All authors read and approved the final manuscript submission.

Competing interests

The authors declare that they have no competing interests.

Author information

Authors and affiliations.

Department of Textile & Clothing Technology, University of Moratuwa, Moratuwa, Sri Lanka

D. G. K. Dissanayake & Thushari Wanniarachchi

Division of Polymer, Textile & Chemical Engineering Technology, Institute of Technology, University of Moratuwa, Moratuwa, Sri Lanka

Srimala Perera

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to D. G. K. Dissanayake .

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License ( http://creativecommons.org/licenses/by/4.0/ ), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Reprints and permissions

About this article

Cite this article.

Dissanayake, D.G.K., Perera, S. & Wanniarachchi, T. Sustainable and ethical manufacturing: a case study from handloom industry. Text Cloth Sustain 3 , 2 (2017). https://doi.org/10.1186/s40689-016-0024-3

Download citation

Received : 30 August 2016

Accepted : 29 December 2016

Published : 13 January 2017

DOI : https://doi.org/10.1186/s40689-016-0024-3

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Sustainability

- Handloom textiles

Getting Technical: A case study with Balas Textile

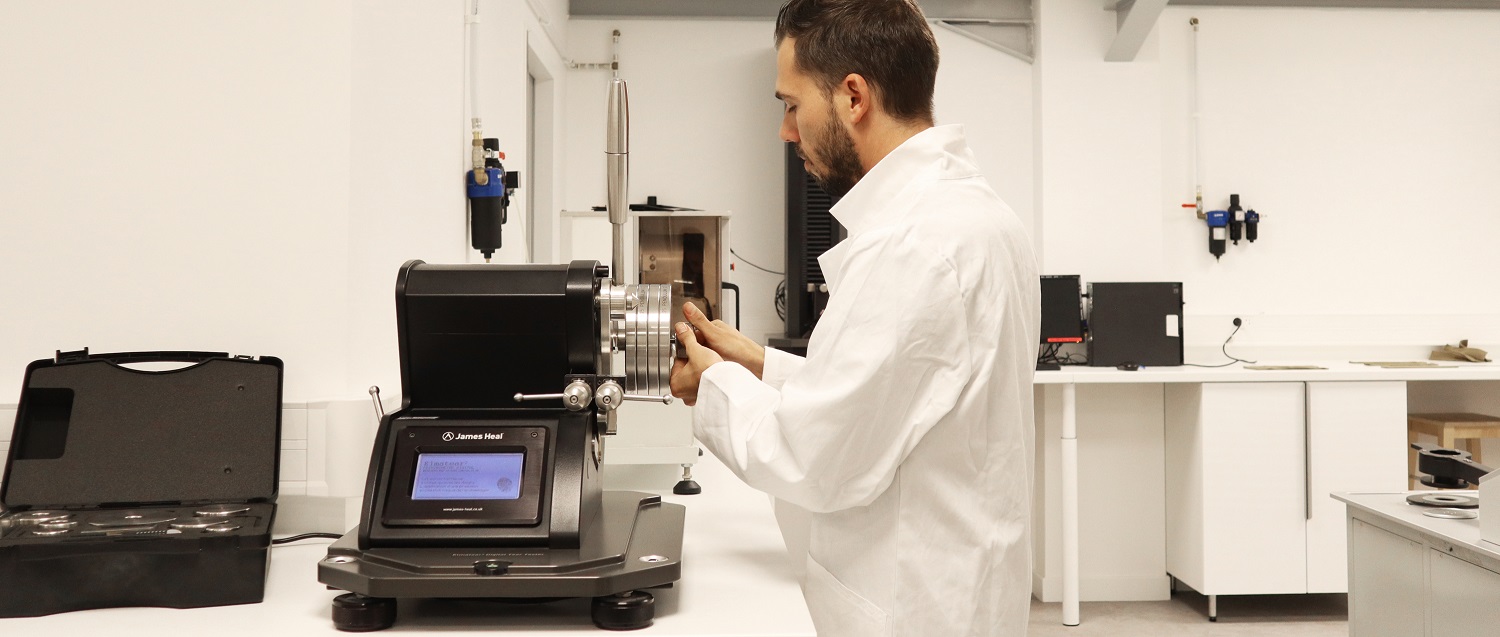

In our latest customer case study, we spoke to Sabrina Mimoune, Quality Manager and Alan Badrov, Lab Manager at French company Balas Textile, to discuss the importance of testing technical textiles and their experiences using James Heal’s instruments.

A leader in technical fabric production

Balas Textile is a manufacturer of technical textiles, specialising in the production of water repellent and technical fabrics, primarily serving the military, PPE, luxury goods and sports apparel sectors. Balas Textile is vertically integrated with its own in-house testing laboratory, along with weaving and knitting. However, Balas Textile does not manufacture clothing, it provides fabrics that will be used in the manufacture of the final garment.

“We undertake a number of different test types. From physical properties, to laundering, comfort testing to torque testing.”

In-house laboratory for reactive and proactive testing

Sabrina has worked in the Balas Quality Department for the last three years, and Alan has held the role of lab manager for four years. During this time, the company has re-developed its in-house textile testing capability and invested in an internal laboratory for R&D as well as quality and production testing. Working closely with James Heal’s channel partner in France, VVC , Balas Textile chose to equip the lab with James Heal instruments, due to their trust in the brand and the quality of the instruments.

Instruments used in the Balas Textile Lab

Balas Textile use a number of James Heal textile testing instruments in their laboratory including:

- AquAbrasion

- Spray Rate Tester

- Perspirometers

“We are very happy with the knowledge and support provided by James Heal and VVC,” says Alan. “We consider VVC a very important partner, as we trust that they will follow our journey to continuously improve the laboratory. We can rely on the support from both VVC and James Heal for technical requirements. We always get quick responses and strong support.”

With a vision to continually evolve and improve the lab, says Alan, Balas Textile plans to triple the size of the lab in the coming year and need more testing equipment. “It is of no question that we will continue to work with VVC and we will specify James Heal instruments for their exceptional quality and precision”, added Alan.

An evolution in demand

Sabrina says that Balas Textile has seen a surge in demand from the international military sector, who are exploring ways to make military textiles more durable whilst prioritising safety and comfort. The latter focusing on making the materials more lightweight yet robust, and more breathable with good moisture management and wicking properties. Furthermore, personal protective fabrics have been a growing category for the manufacturer, says Sabrina, with a rise in fashion influence in the design and fit of PPE, and more awareness of ‘feeling good’ and prioritising wearer comfort.

“Having an in-house laboratory has been fundamental to Balas Textile being able to respond rapidly to market demand, allowing us to quickly focus our R&D testing on new fabrics such as anti-stain technology or odour-resistant fabric, using the lab for exploring new and novel materials.”

Early adopters of new technology

A good example of the Balas Textile approach to R&D was being one of the first textile manufacturers to purchase a James Heal Aquabrasion testing instrument in 2019. The Aquabrasion is a wet abrasion tester based on the traditional Martindale instrument. It uses a controlled pump system to dose fabric specimens with liquid which keeps the specimen wet for the duration of the test. De-ionised water can be used to replicate rain, or a perspiration solution can be used to replicate sweat.

“Testing for abrasion under wet conditions is a very interesting concept,” comments Alan. “We were intrigued to try this out and test our swimwear materials using the Aquabrasion, rather than a tensile tester, using the standard abrasion test (ISO 19247-2).”

So far tests have been conducted continuously using only tap water. The next step with Aquabrasion, adds Alan, is to test using chlorinated water as well as perspiration, to explore the impact these have on the material’s performance in true ‘user’ conditions.

According to Sabrina, the Aquabrasion has attracted a lot of interest from visitors to the internal laboratory, with many questions about the machine’s purpose and applications.

“We have found that the Aquabrasion is versatile as it can be adapted to specific use cases. It is an accurate and precise alternative to how we’ve tested materials before, such as swimwear. We’ve gained much more insight into real-life conditions than with other instruments we have used to conduct this test method before.”

And finally

In conclusion, Balas Textile has made significant investment in expansion of the lab and testing facilities, making improvements in energy consumption and purchase of new equipment amounting to almost €400,000 in 2022, further strengthening their partnership with VVC.

VVC Sales Manager Grégoire Ghilbert added, “Balas Textile is a long-standing partner of VVC. Our collaboration around the development of their laboratory and the calibration of their equipment are always extremely constructive and allow our mutual teams to develop their skills.

It is with pleasure that VVC continues to accompany Balas Textile in the implementation of new performance wear tests such as Aquabrasion.”

More articles

A simple guide to tensile testing - eBook download

Applications Insight: Dry Rate Testing

Expert Q&A: Durability Testing In The Age of Fast Fashion & Diverse Performance

Pioneering sustainable water repellency testing with TruRain

Tear testing: Your questions answered

AquAbrasion: Assessing the true impact of the outdoors on outdoor wear

A simple guide to: Hydrostatic head testing

Applications insight: Military textiles

The Lab Manager's Guide to Performance Testing

Phenolic Yellowing: The scientific reason that white clothes can go yellow

Applications insight: Nonwovens testing

[Essentials] Martindale - What it does and how it works

Case studies.

Discover companies who we've worked with that use our instruments, test materials and services.