Explore Lean Thinking and Practice / Problem-Solving

Problem-Solving

Explore the process that’s foundational to assuring every individual becomes engaged by arming them with methods they can use to overcome obstacles and improve their work process.

Overcoming obstacles to achieve or elevate a standard

In a lean management system, everyone is engaged in ongoing problem-solving that is guided by two characteristics:

- Everything described or claimed should be based on verifiable facts, not assumptions and interpretations.

- Problem-solving is never-ending; that is, it begins rather than ends when an improvement plan is implemented. The implementation process is a learning opportunity to discover how to make progress toward the target condition.

Lean thinkers & practitioners understand that the problem-solving process is impeded if you make the common mistake of mechanically reaching for a familiar or favorite problem-solving methodology or, worse, jump quickly to a solution.

Leaders and teams avoid this trap by recognizing that most business problems fall into four categories, each requiring different thought processes, improvement methods, and management cadences.

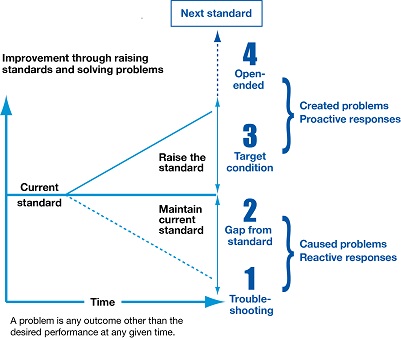

The Four Types of Problems

Type 1: Troubleshooting: reactive problem-solving that hinges upon rapidly returning abnormal conditions to known standards. It provides some immediate relief but does not address the root cause.

Type 2: Gap from Standard: structured problem-solving that focuses on defining the problem, setting goals, analyzing the root cause, and establishing countermeasures, checks, standards, and follow-up activities. The aim is to prevent the problem from recurring by eliminating its underlying causes.

Type 3: Target Condition: continuous improvement ( kaizen ) that goes beyond existing standards of performance. It may utilize existing methods in new, creative ways to deliver superior value or performance toward a new target state of improvement.

Type 4: Open-ended: innovative problem-solving based on creativity, synthesis, and recognition of opportunity. It establishes new norms that often entail unexpected products, processes, systems, or value for the customer well beyond current levels.

By helping everyone in the organization to understand the importance of taking ownership of seeing and solving all types of problems, lean thinking & practice:

- Engenders a sense of empowerment and autonomy in all workers, which in turn promotes engagement in and ownership of the work process

- Enables organizations to overcome obstacles at their source, so they do not become more significant problems upstream

Ultimately, building a problem-solving culture creates a competitive advantage that is difficult for competitors to match.

Relevant Posts

Problem Solving

Why the A3 Process Involves More than Filling in Boxes

Article by Tracey Richardson

Big Problems? Start Small

Article by Josh Howell

What’s your problem

Article, Video by John Shook

Recent Posts

Revolutionizing Logistics: DHL eCommerce’s Journey Applying Lean Thinking to Automation

Podcast by Matthew Savas

Transforming Corporate Culture: Bestbath’s Approach to Scaling Problem-Solving Capability

Teaching Lean Thinking to Kids: A Conversation with Alan Goodman

Podcast by Alan Goodman and Matthew Savas

Relevant Products

Four Types of Problems

by Art Smalley

Managing to Learn: Using the A3 management process

by John Shook

Getting Home

by Liz McCartney and Zack Rosenburg

Steady Work

by Karen Gaudet

Relevant Events

June 10, 2024 | Coach-Led Online Course and Oakland University in Rochester, Michigan

Managing to Learn

June 12, 2024 | Morgantown, PA

Building a Lean Operating and Management System

November 12, 2024 | Coach-Led Online Course

Improvement Kata/Coaching Kata

Be the first to learn of new learning opportunities and the latest practical, actionable information. subscribe to an lei newsletter., join us on social, privacy overview.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vivamus convallis sem tellus, vitae egestas felis vestibule ut.

Error message details.

Reuse Permissions

Request permission to republish or redistribute SHRM content and materials.

How to Coach Problem Solving

The key to training employees to be better problem solvers is to transform managers into coaches. The transformation is difficult but will revolutionize your organization.

Coaching problem solving is the greatest leverage point you have to drive effective problem solving. If you want to coach problem solving, then you need to build coaches. Far too few lean transformation road maps involve an explicit plan for doing so. They focus on training and try to train up a critical mass of their organization on problem solving. But what happens when someone finishes their training? They try to apply what they learned, they struggle, they may fail, and finally, they give up. Why? Because, especially in the early stages of our individual learning, we need coaches who help us close the gap between knowledge and capability, between understanding something and being able to use it. I have advised several companies to pump the brakes, slow down their training and focus more on building coaching capacity, because otherwise, people would have become frustrated.

What is the target condition for an organization with coaches? Every employee should be no more than one degree removed from a coach. In other words, every employee should be able to access a coach where and when they need it. That means coaches must be plentiful, available and connected. If an employee on the evening shift of a multishift operation has a problem they are engaged in solving, then what happens if all the coaches are on the day shift? Most likely, they never get the coaching they need because neither the problem nor the learning can wait.

Evaluate your coaching capacity by observing, or even surveying, with this question: Do you have access to a problem-solving coach where and when you need it? I do not recommend putting a lot of energy into trying to calculate a number, because it is often a moving target. As the learning increases, so does the demand for coaches, but then as the capability grows in the critical mass of the organization, the demand will drop, at least until you raise expectations again or the conditions get more complex for other reasons (a merger, a strategic pivot or an economic crisis, as examples).

The Manager as Coach

There is one guaranteed way to ensure every employee is no more than one degree removed from a coach: make coaching the priority for every manager. One-on-one meetings become coaching sessions. Staff meetings can become shared-learning coaching sessions. The strongest lean organizations I have observed make this one of the core elements of their infrastructure.

Several supporting factors must also change to enable this goal.

1. Managers must make choices situation by situation about when they are a manager first and when they are a coach first. This is a trade-off between short-term performance and long-term capability for future performance. If the incentive system, both formal and cultural, is more focused on short-term performance than building long-term capability, then the manager-as-coach scheme will fail. As one former Toyota manager told me, "I cannot get promoted until my employees are capable of doing my job. My number-one priority is developing my team." The best signal you can send is in promotions, as this manager indicated. Not only will it be clear who "gets ahead" in the organization, but those managers, once promoted, will place value on this for their decisions.

2. You need to build mechanisms and processes that enable this relationship. For example, look at your employee evaluation system. Is coaching built in or is its primary purpose to document and reward outcome-based performance? It can do both, but you can build the backbone of your system primarily for only one or the other.

3. You need to think about how many team members a manager can coach without diluting and sacrificing quality. Organizations that are focused on coaching often have a smaller span of control for each manager, but because they gain more from those employees as a result of the coaching, the payout is still positive. However, do not put the extra managers in place before you've built the capability.

Otherwise, you will have more managers committed to the old expectations and who build up greater resistance to becoming coaches. Instead, start shifting managers into being capable coaches, and they will gradually force the right ratio because they start to shape their environment to be optimal for coaching. I know one executive who makes an effort to keep their calendar very clear and open so they are available to their team for coaching or other needs. This is the kind of ownership of their coaching that managers should aspire to.

Here is the hard part: building that capability and culture, with that many managers, is difficult and takes time. It is a long-term decision to pursue this route. Not only do you face a real risk of managers diminishing what was working in order to shift to coaching, but they may not be good at it. They must learn, through practice, on their way to success. This means failures along the way. You must be accepting of those failures and perhaps supplement the organization with other crutches to prop it up during the transition.

I cannot think of many investments with a higher and more sustainable long-term payout than building an organization where every manager is a coach. However, I also cannot think of many investments that require more effort, persistence and patience.

Jamie Flinchbaugh is an entrepreneur, senior executive, consultant and board member. He is the author of People Solve Problems: The Power of Every Person, Every Day, Every Problem and The Hitchhiker's Guide to Lean: Lessons from the Road.

Related Content

A 4-Day Workweek? AI-Fueled Efficiencies Could Make It Happen

The proliferation of artificial intelligence in the workplace, and the ensuing expected increase in productivity and efficiency, could help usher in the four-day workweek, some experts predict.

How One Company Uses Digital Tools to Boost Employee Well-Being

Learn how Marsh McLennan successfully boosts staff well-being with digital tools, improving productivity and work satisfaction for more than 20,000 employees.

Advertisement

Artificial Intelligence in the Workplace

An organization run by AI is not a futuristic concept. Such technology is already a part of many workplaces and will continue to shape the labor market and HR. Here's how employers and employees can successfully manage generative AI and other AI-powered systems.

HR Daily Newsletter

New, trends and analysis, as well as breaking news alerts, to help HR professionals do their jobs better each business day.

Success title

Success caption

Art of Lean

10 tips for coaching problem solving.

Have you ever struggled to give good coaching advice to someone delivering a problem solving presentation? Giving good feedback is difficult and takes practice. Giving feedback however is just one small part of coaching. In this video below I give some thoughts pertaining to the overall process of coaching and improving problem solving skills.

I gave this presentation to one of my clients as part of a “Lunch and Learn” series and decided to turn it into a short video. It is aimed at the topic of more effective coaching in problem solving. Most people or organizations rely upon a give technique or particular style. Usually it revolves around just asking open-ended questions or one or two specific points of advice. There is nothing wrong with that tactic. However it is not enough to help most people improve or drive fundamental change to your organizational culture.

In the video below I outline ten specific things I try when I work with organizations on the topic of problem solving and coaching. I have more specific and situational topics as well but these ten are useful in just about any situation. I use them in kid’s sports, martial arts, and of course my client work. You can probably massage them in different ways to fit your needs. Good luck with your coaching work!

0:54 Tip #1 Sharpen you sword

3:00 Tip #2 Plan for every person

3:55 Tip #3 Video practice

6:08 Tip #4 Prepare the environment

7:15 Tip #5 Embrace thinking patterns

8:55 Tip #6 Coaching styles

10:45 Tip #7 Role for everyone

12:21 Tip #8 Utilize job aids

14:01 Tip #9 Time frame management

16:15 Tip #10 Make it fun

17:18 Summary

Good luck with your coaching work!

Share this:

- What is Lean?

- Our Approach To Lean

- History & What We’ve Done

- Lean Research

- Lean Capability Development

- Login / Sign up

Sign up and join the community

Email address *

Subscribe to our newsletter

Please select all the ways you would like to hear from us Email

Your personal data will be used to support your experience throughout this website, to manage access to your account, and for other purposes described in our privacy policy .

Home > How do you Engage and Coach Problem Solving Thinkers

How do you Engage and Coach Problem Solving Thinkers

30th March 2017 - David Brunt

As a Lean Thinker I’m always on the lookout for ways to help others improve (and improve myself at the same time!) Traditionally there have been lots of books and articles to wade through and more recently YouTube talks, podcasts and webinars to look at. There are also a host of workshops and events offered.

Each year I try to attend The Lean Enterprise Institute’s (LEI) Transformation Summit. I did so last week where I spoke at their annual event in Carlsbad, California. When I’m not conducting a workshop or learning session I like to put myself into the shoes of the customer and participate in sessions offered by LEI’s faculty. The faculty was a “neat idea” of LEI’s founder Jim Womack who wanted to bring lean to a much wider audience. He encouraged people with some lean knowledge to share it as a short course that others could attend. For those of us wanting to share we had a development opportunity – testing different materials, exercises and refining cases that could be written up. The purpose was to create reusable knowledge to help an attendee with their lean implementation and develop them as individuals – at the same time!

Over the years I’ve been to a lot of workshops! Most I’ve only needed to attend once, but some I’ve attended several times as I feel I either learn something new or (more accurately) learn at a deeper level each time I attend. Examples of serial workshop attendance that spring to mind are the early value stream mapping workshops Mike Rother developed, Art Smalley’s sessions on creating basic stability and creating level pull and John Shook’s sessions on lean leadership and A3 thinking. Attending those workshops and then putting in the essential hours of practice at the workplace helped me develop. Subsequent workshop attendance gave me time to reflect so I could go back to the workplace with new insights to practice again.

Also on my list of faculty workshops to attend multiple times are those given by David Verble. I’m sure David won’t mind me saying that he is probably not as well-known as Rother, Smalley or Shook (my hypothesis for this is because his publications have always been done with a large team of people rather than with one or two other authors.) However, David’s workshops are the ones I feel I need to revisit – even though we’ve taught together a couple of times.

As part of our workshop programme this year we’ve asked David to conduct a two-day workshop titled “ Leading in a Continuous Improvement Culture: Engaging and Coaching Problem Solving Thinkers. ” In the workshop David will explain how to:

- Use Value-Stream Thinking to identify problems at process level that are affecting operational performance

- Give employees responsibility for addressing the right process-level problems at the right places in the work flow

- Model, teach and insist on Plan-Do-Check-Adjust Problem Solving based on grasp of the actual conditions of problems

- Create fundamentally different relationships with employees and others that focus on coaching and developing their problem solving capability

David Verble is the coaches coach. His insights on the technique of “humble enquiry” are essential for anyone wanting to lead using Lean Thinking as it helps people move through the PDCA cycle. David will help you practice humble enquiry. He’ll show you the most effective way to ask questions to begin the problem solving process and he’ll have you practice and improve your questioning technique and your problem solving skills.

Mastering the content of David’s workshops are probably the most portable skills a Lean Thinker needs. Anyone with a sincere interest in lean and people development will come away with a ton of useful insights and practical next steps. I hope to see you next week in Manchester.

- Construction

- Manufacturing

- Public Sector

- Retail & Hospitality

- Supply Chain

- Capability Development

- Lean Leadership

- Lean Principles

- Management System

- Process Improvement

- Product Development

- Tools & Techniques

- Transformation

- Demand Analysis

- Flow Costing

- Lean & Green

- lean certification

- Lean Digital

- lean learning

- Lean Summit

- Lean Thinking

- Lean Transformation Framework

- Managment Routines

- People Capability

- Problem Solving

- product development

- Purpose Process People

- Rapid Problem Solving

- Standardised Work

- Supply Chain Management

- Teach Poster

- Training Within Industry (TWI)

- UK Lean Summit

- Value Stream Analysis

- Value Stream Mapping (VSM)

- Value Streams

- Visual Management

- Guide: Problem Solving

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: January 7, 2024

- Learn Lean Sigma

Problem-solving stands as a fundamental skill, crucial in navigating the complexities of both everyday life and professional environments. Far from merely providing quick fixes, it entails a comprehensive process involving the identification, analysis, and resolution of issues.

This multifaceted approach requires an understanding of the problem’s nature, the exploration of its various components, and the development of effective solutions. At its core, problem-solving serves as a bridge from the current situation to a desired outcome, requiring not only the recognition of an existing gap but also the precise definition and thorough analysis of the problem to find viable solutions.

Table of Contents

What is problem solving.

At its core, problem-solving is about bridging the gap between the current situation and the desired outcome. It starts with recognizing that a discrepancy exists, which requires intervention to correct or improve. The ability to identify a problem is the first step, but it’s equally crucial to define it accurately. A well-defined problem is half-solved, as the saying goes.

Analyzing the problem is the next critical step. This analysis involves breaking down the problem into smaller parts to understand its intricacies. It requires looking at the problem from various angles and considering all relevant factors – be they environmental, social, technical, or economic. This comprehensive analysis aids in developing a deeper understanding of the problem’s root causes, rather than just its symptoms.

Finally, effective problem-solving involves the implementation of the chosen solution and its subsequent evaluation. This stage tests the practicality of the solution and its effectiveness in the real world. It’s a critical phase where theoretical solutions meet practical application.

The Nature of Problems

The nature of the problem significantly influences the approach to solving it. Problems vary greatly in their complexity and structure, and understanding this is crucial for effective problem-solving.

Simple vs. Complex Problems : Simple problems are straightforward, often with clear solutions. They usually have a limited number of variables and predictable outcomes. On the other hand, complex problems are multi-faceted. They involve multiple variables, stakeholders, and potential outcomes, often requiring a more sophisticated analysis and a multi-pronged approach to solving.

Structured vs. Unstructured Problems : Structured problems are well-defined. They follow a specific pattern or set of rules, making their outcomes more predictable. These problems often have established methodologies for solving. For example, mathematical problems usually fall into this category. Unstructured problems, in contrast, are more ambiguous. They lack a clear pattern or set of rules, making their outcomes uncertain. These problems require a more exploratory approach, often involving trial and error, to identify potential solutions.

Understanding the type of problem at hand is essential, as it dictates the approach. For instance, a simple problem might require a straightforward solution, while a complex problem might need a more comprehensive, step-by-step approach. Similarly, structured problems might benefit from established methodologies, whereas unstructured problems might need more innovative and creative problem-solving techniques.

The Problem-Solving Process

The process of problem-solving is a methodical approach that involves several distinct stages. Each stage plays a crucial role in navigating from the initial recognition of a problem to its final resolution. Let’s explore each of these stages in detail.

Step 1: Identifying the Problem

Step 2: defining the problem.

Once the problem is identified, the next step is to define it clearly and precisely. This is a critical phase because a well-defined problem often suggests its solution. Defining the problem involves breaking it down into smaller, more manageable parts. It also includes understanding the scope and impact of the problem. A clear definition helps in focusing efforts and resources efficiently and serves as a guide to stay on track during the problem-solving process.

Step 3: Analyzing the Problem

Step 4: generating solutions, step 5: evaluating and selecting solutions.

After generating a list of possible solutions, the next step is to evaluate each one critically. This evaluation includes considering the feasibility, costs, benefits, and potential impact of each solution. Techniques like cost-benefit analysis, risk assessment, and scenario planning can be useful here. The aim is to select the solution that best addresses the problem in the most efficient and effective way, considering the available resources and constraints.

Step 6: Implementing the Solution

Step 7: reviewing and reflecting.

The final stage in the problem-solving process is to review the implemented solution and reflect on its effectiveness and the process as a whole. This involves assessing whether the solution met its intended goals and what could have been done differently. Reflection is a critical part of learning and improvement. It helps in understanding what worked well and what didn’t, providing valuable insights for future problem-solving efforts.

Tools and Techniques for Effective Problem Solving

Problem-solving is a multifaceted endeavor that requires a variety of tools and techniques to navigate effectively. Different stages of the problem-solving process can benefit from specific strategies, enhancing the efficiency and effectiveness of the solutions developed. Here’s a detailed look at some key tools and techniques:

Brainstorming

Swot analysis (strengths, weaknesses, opportunities, threats), root cause analysis.

This is a method used to identify the underlying causes of a problem, rather than just addressing its symptoms. One popular technique within root cause analysis is the “ 5 Whys ” method. This involves asking “why” multiple times (traditionally five) until the fundamental cause of the problem is uncovered. This technique encourages deeper thinking and can reveal connections that aren’t immediately obvious. By addressing the root cause, solutions are more likely to be effective and long-lasting.

Mind Mapping

Each of these tools and techniques can be adapted to different types of problems and situations. Effective problem solvers often use a combination of these methods, depending on the nature of the problem and the context in which it exists. By leveraging these tools, one can enhance their ability to dissect complex problems, generate creative solutions, and implement effective strategies to address challenges.

Developing Problem-Solving Skills

Developing problem-solving skills is a dynamic process that hinges on both practice and introspection. Engaging with a diverse array of problems enhances one’s ability to adapt and apply different strategies. This exposure is crucial as it allows individuals to encounter various scenarios, ranging from straightforward to complex, each requiring a unique approach. Collaborating with others in teams is especially beneficial. It broadens one’s perspective, offering insights into different ways of thinking and approaching problems. Such collaboration fosters a deeper understanding of how diverse viewpoints can contribute to more robust solutions.

Reflection is equally important in the development of problem-solving skills. Reflecting on both successes and failures provides valuable lessons. Successes reinforce effective strategies and boost confidence, while failures are rich learning opportunities that highlight areas for improvement. This reflective practice enables one to understand what worked, what didn’t, and why.

Critical thinking is a foundational skill in problem-solving. It involves analyzing information, evaluating different perspectives, and making reasoned judgments. Creativity is another vital component. It pushes the boundaries of conventional thinking and leads to innovative solutions. Effective communication also plays a crucial role, as it ensures that ideas are clearly understood and collaboratively refined.

In conclusion, problem-solving is an indispensable skill set that blends analytical thinking, creativity, and practical implementation. It’s a journey from understanding the problem to applying a solution and learning from the outcome.

Whether dealing with simple or complex issues, or structured or unstructured challenges, the essence of problem-solving lies in a methodical approach and the effective use of various tools and techniques. It’s a skill that is honed over time, through experience, reflection, and the continuous development of critical thinking, creativity, and communication abilities. In mastering problem-solving, one not only addresses immediate issues but also builds a foundation for future challenges, leading to more innovative and effective outcomes.

- Mourtos, N.J., Okamoto, N.D. and Rhee, J., 2004, February. Defining, teaching, and assessing problem solving skills . In 7th UICEE Annual Conference on Engineering Education (pp. 1-5).

- Foshay, R. and Kirkley, J., 2003. Principles for teaching problem solving. Technical paper , 4 (1), pp.1-16.

Q: What are the key steps in the problem-solving process?

A : The problem-solving process involves several key steps: identifying the problem, defining it clearly, analyzing it to understand its root causes, generating a range of potential solutions, evaluating and selecting the most viable solution, implementing the chosen solution, and finally, reviewing and reflecting on the effectiveness of the solution and the process used to arrive at it.

Q: How can brainstorming be effectively used in problem-solving?

A: Brainstorming is effective in the solution generation phase of problem-solving. It involves gathering a group and encouraging the free flow of ideas without immediate criticism. The goal is to produce a large quantity of ideas, fostering creative thinking. This technique helps in uncovering unique and innovative solutions that might not surface in a more structured setting.

Q: What is SWOT Analysis and how does it aid in problem-solving?

A : SWOT Analysis is a strategic planning tool used to evaluate the Strengths, Weaknesses, Opportunities, and Threats involved in a situation. In problem-solving, it aids by providing a clear understanding of the internal and external factors that could impact the problem and potential solutions. This analysis helps in formulating strategies that leverage strengths and opportunities while mitigating weaknesses and threats.

Q: Why is it important to understand the nature of a problem before solving it?

A : Understanding the nature of a problem is crucial as it dictates the approach for solving it. Problems can be simple or complex, structured or unstructured, and each type requires a different strategy. A clear understanding of the problem’s nature helps in applying the appropriate methods and tools for effective resolution.

Q: How does reflection contribute to developing problem-solving skills?

A : Reflection is a critical component in developing problem-solving skills. It involves looking back at the problem-solving process and the implemented solution to assess what worked well and what didn’t. Reflecting on both successes and failures provides valuable insights and lessons, helping to refine and improve problem-solving strategies for future challenges. This reflective practice enhances one’s ability to approach problems more effectively over time.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

8 Tips to Transition from Problem Solver to Problem Solving Coach

by Jamie Parker | Apr 22, 2018 | People Development

I was pretty proud of myself. It didn’t matter what question a team member came to me with – I could almost always reply with an eloquent answer on the fly. It was like magic, and I thought I was fantastic!

Boy, was I wrong. (Keep reading to find out how)

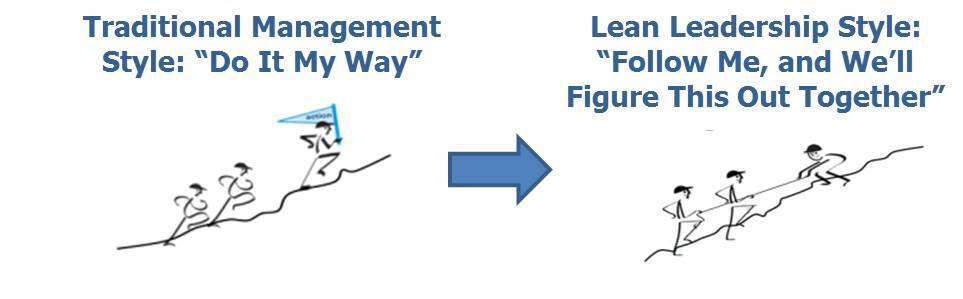

Problem Solvers in Traditional Management

In traditional organizations, problem solving is often limited to support groups at the corporate office or the engineers or the managers in a plant.

In fact, many of us were promoted into management or through the ranks of management because we were good at two things: (1) executing our current job and (2) solving problems (figuring it out, getting it done, overcoming obstacles, making it happen – all variations of “solving problems” in the traditional management sense).

We may actually see (or just think we see) the answers a little easier than others. We have experience and so sometimes we “just know.” And we have a bias for action.

So, we – the managers of the operation – are often the traditional problem solvers.

Who Solves Problems in Lean

With Lean, though, problems are meant to be solved within the context of the process. If a problem is at the line processes – then it should be solved at the line. Not by the plant manager who is removed from the process (though managers do need to play the role of teacher, coach, and mentor).

Managers still solve problems – but instead of solving line process problems, they should solve problems that occur in their work processes (including leading culture, developing people, cross-functional collaboration problems, etc.).

As Lean practitioners, we are focused on working together to create more value.

More people solving more problems creates more value. Therefore, one responsibility as Lean leaders is to develop the problem-solving capabilities of team members throughout the organization.

That means that effective Lean leaders don’t jump in and solve all of the problems. Instead they teach and coach the problem-solving capabilities of the team so problems are solved at the right steps.

We are often so used to jumping in to be the problem solvers and the answer-givers that even when we are practicing Lean those old habits still show up.

But shifting to solve problems at the right step is a necessary shift to transform from traditional management to effective leadership.

How My Answers Were Wrong

Years ago, I attended a workshop and we did a question-asking exercise. And in that moment, I realized just how hard it was for me to keep my mouth shut, not give the answer, and instead simply ask good, open-ended questions that didn’t lead the team member where I wanted to go.

You see, even when I was technically asking a question, I was actually influencing the other person’s mental process. I was perhaps telling in a form of a question. Or maybe more subtly I was leading the team member to a focus.

Asking “have you thought about trying X” is often received as telling “you should do x”.

And to cap it off, I was making assumptions in the process – thinking that I “knew” based off my previous experience rather than recognizing that I didn’t actually know the answer in this situation.

In the book Humble Inquiry, Edgar Schein describes what he calls humble inquiry as “the skill and the art of drawing someone out, of asking questions to which you do not already know the answer, of building relationship based on curiosity and interest in the other person.”

Ahhh – curiosity and interest. The secret sauce.

8 Tips to Become a Problem Solving Coach

Transitioning from problem solver to problem solving coach isn’t easy. Here are some tips to help you out.

1. Believe that you can learn from team members

That’s right. You don’t have all the answers. And as long as you believe you do, you’re going to have a hard time stepping back and coaching problem solving. If you’re not there yet, try out tip #4 to open yourself up to the possibility.

2. Tell your team how you are trying to change

Be honest, transparent and vulnerable. Let your team know that you are trying to change. You want to stop jumping in and dictating answers and instead help coach problem solving. Tell them you know you’re going to fail at it as you have some old habits to break, but that you’re asking for their help along the way.

3. Ask yourself – in what process is the problem occurring?

To help slow yourself down and solve problems at the right steps, deliberately ask yourself “in what process is the problem occurring?” This will give you the context to know which team members you need to partner with and coach through the problem-solving process.

4. Be curious

I think curiosity is the least-talked about component of effective leadership. Put yourself in a place of curiosity. Make “I wonder” one of your most-used phrases. I wonder what I can learn here. I wonder what ideas team members have. I wonder what the true root cause is. I wonder what factors I haven’t considered. I wonder what possible countermeasures the team will come up with that I never would.

5. Prepare Good Question samples in advance

Early on, this transition from problem solver to problem solving coach is really, really hard. Your old habits are going to keep showing up. Get a leg up by writing out some sample Good Questions (open-ended, curious, non-leading questions) in advance. You can also use statements like “tell me more.” This isn’t a script you have to follow, but having these prepared and available (potentially even kept in your pocket for quick reference) can help you extinguish old habits to make room for new coaching habits.

6. Start with “What do you think?”

Sometimes the hardest part is getting started. So prepare yourself to start a problem coaching discussion with “What do you think?” This is also a great question to have ready every time a team member comes to you and asks what they should do!

7. Bite your tongue

I know – easier said than done. What can you do to keep your jumping-in reflexes at bay and give yourself time to consider those good question samples you just developed? Not sure? Try counting to 3 before asking your next question. There may be a little awkward silence at first – but since you already told your team what you’re up to, they will understand. And sometimes, that silence gives the team member an opportunity to fill it with their own additional thoughts!

8. Reflect and adjust

That’s right. We need to apply PDSA to our own leadership. After you practice coaching, stop and reflect on what you expected to happen, what actually happened, and what you learned. Write down how you want to adjust and then practice this adjustment. In the next coaching

Solving problems at the right steps is a necessary shift to transform from traditional management to effective leadership. And that means transitioning from the primary problem solver to a problem solving coach.

Take Action to Transform to Effective Lean Leadership

Try it out. Spend a week deliberately stopping yourself from giving the answer. . . Including in seemingly innocent ways like “Have you thought about trying ABC”. Even in these softly couched phrases, we are still giving the answers.

Try it for a week. Ask yourself, “Was that a good question?” Did you come from a place of curiosity and interest?

I bet it’s more difficult than you expect!

Be sure to share your tips and good practices in the comments so we can learn from each other.

Did you miss the previous four Lean leadership shifts? Check them out here:

- Lead with Respect for People

- Redefine Winning

- Put Results In Their Place

- Select New Heroes

And don’t forget to download a FREE PDF to assess and track your improvement in fifteen Process + Results Lean Leadership areas! Get your download here.

I’m a recovering Command-and-Control Manager who’s now on a mission to make the world of work more human. With a soft spot in my heart for Ops Managers, this Lean blog gives you the straight talk combining Lean, Leadership, and the real challenges of operations management.

IMAGES

VIDEO

COMMENTS

The Four Types of Problems. Type 1: Troubleshooting: reactive problem-solving that hinges upon rapidly returning abnormal conditions to known standards. It provides some immediate relief but does not address the root cause. Type 2: Gap from Standard: structured problem-solving that focuses on defining the problem, setting goals, analyzing the ...

Coaching problem solving is the greatest leverage point you have to drive effective problem solving. If you want to coach problem solving, then you need to build coaches. Far too few lean ...

Coaching your team members in lean problem-solving can bring many benefits to your organization, your team, and yourself. For instance, it can lead to improved performance and quality, as well as ...

Do you need to learn how to improve your problem-solving capabilities or retain someone to get over a specific hurdle? That's where Lean Coach® comes in. Our team of industry experts provides Lean Consulting, as well as Lean Coaching and Lean Six Sigma Training, leveraging principles from Lean, Data Analytics, Theory of Constraints, and the ...

3. Practice lean coaching. Be the first to add your personal experience. 4. Model lean coaching. Be the first to add your personal experience. 5. Evaluate lean coaching. Be the first to add your ...

For you as a coach, it's not about the problem! 2. Stop Giving the Answers. You can't help yourself. You learned from a young age that having the right answer is a good thing. You learned that solving problems and fixing things gets you promoted. You learned that your job as a leader is to remove obstacles for your team, even if it means ...

DMAIC is the problem-solving approach that drives Lean Six Sigma. It's a five-phase method—Define, Measure, Analyze, Improve and Control—for improving existing process problems with unknown causes. DMAIC is based on the Scientific Method and it's pronounced "duh-may-ik.". Originally published on August 24th, 2017, this article was ...

In addition I will post the time stamps here as well for each section: 0:00 Intro. 0:54 Tip #1 Sharpen you sword. 3:00 Tip #2 Plan for every person. 3:55 Tip #3 Video practice. 6:08 Tip #4 Prepare the environment. 7:15 Tip #5 Embrace thinking patterns. 8:55 Tip #6 Coaching styles. 10:45 Tip #7 Role for everyone.

Give employees responsibility for addressing the right process-level problems at the right places in the work flow. Model, teach and insist on Plan-Do-Check-Adjust Problem Solving based on grasp of the actual conditions of problems. Create fundamentally different relationships with employees and others that focus on coaching and developing ...

The process of problem-solving is a methodical approach that involves several distinct stages. Each stage plays a crucial role in navigating from the initial recognition of a problem to its final resolution. Let's explore each of these stages in detail. Step 1: Identifying the Problem. This is the foundational step in the problem-solving process.

Problem solving has 4 key elements. First is we need to do it now while the evidence is fresh. "Go and See" at the workplace or Gemba in Japanese. Will not solve problems in the office or behind the computer. Just like CSI ! Maximise the chance of seeing the problem and getting the best data /evidence you can.

Problem Solving Coaching & Feedback Form Source: Art Smalley, The Lean Post Toyota's TQM-based approach evaluates what the learner's student did against the standard. The coach assigns a rating of 1 when this fails to meet the expectation, a 2 when it meets expectation, and a 3 when it exceeds expectation.

8 Tips to Become a Problem Solving Coach. Transitioning from problem solver to problem solving coach isn't easy. Here are some tips to help you out. 1. Believe that you can learn from team members. That's right. You don't have all the answers. And as long as you believe you do, you're going to have a hard time stepping back and coaching ...

2 Measure the current state. The second principle of Lean problem management is to measure the current state of the problem and the process. This means collecting data and facts that show how the ...

Evaluate solutions. 5. Implement solutions. 6. Learn from problems. Be the first to add your personal experience. 7. Here's what else to consider. Coaching and mentoring are valuable skills that ...

3. Empower your employees. 4. Implement kaizen events. 5. Sustain the improvement. 6. Here's what else to consider. Lean problem-solving is a core skill for employees who want to implement lean ...