- Business Essentials

- Leadership & Management

- Credential of Leadership, Impact, and Management in Business (CLIMB)

- Entrepreneurship & Innovation

- Digital Transformation

- Finance & Accounting

- Business in Society

- For Organizations

- Support Portal

- Media Coverage

- Founding Donors

- Leadership Team

- Harvard Business School →

- HBS Online →

- Business Insights →

Business Insights

Harvard Business School Online's Business Insights Blog provides the career insights you need to achieve your goals and gain confidence in your business skills.

- Career Development

- Communication

- Decision-Making

- Earning Your MBA

- Negotiation

- News & Events

- Productivity

- Staff Spotlight

- Student Profiles

- Work-Life Balance

- AI Essentials for Business

- Alternative Investments

- Business Analytics

- Business Strategy

- Business and Climate Change

- Design Thinking and Innovation

- Digital Marketing Strategy

- Disruptive Strategy

- Economics for Managers

- Entrepreneurship Essentials

- Financial Accounting

- Global Business

- Launching Tech Ventures

- Leadership Principles

- Leadership, Ethics, and Corporate Accountability

- Leading Change and Organizational Renewal

- Leading with Finance

- Management Essentials

- Negotiation Mastery

- Organizational Leadership

- Power and Influence for Positive Impact

- Strategy Execution

- Sustainable Business Strategy

- Sustainable Investing

- Winning with Digital Platforms

Root Cause Analysis: What It Is & How to Perform One

- 07 Mar 2023

The problems that affect a company’s success don’t always result from not understanding how to solve them. In many cases, their root causes aren’t easily identified. That’s why root cause analysis is vital to organizational leadership .

According to research described in the Harvard Business Review , 85 percent of executives believe their organizations are bad at diagnosing problems, and 87 percent think that flaw carries significant costs. As a result, more businesses seek organizational leaders who avoid costly mistakes.

If you’re a leader who wants to problem-solve effectively, here’s an overview of root cause analysis and why it’s important in organizational leadership.

Access your free e-book today.

What Is Root Cause Analysis?

According to the online course Organizational Leadership —taught by Harvard Business School professors Joshua Margolis and Anthony Mayo— root cause analysis is the process of articulating problems’ causes to suggest specific solutions.

“Leaders must perform as beacons,” Margolis says in the course. “Namely, scanning and analyzing the landscape around the organization and identifying current and emerging trends, pressures, threats, and opportunities.”

By working with others to understand a problem’s root cause, you can generate a solution. If you’re interested in performing a root cause analysis for your organization, here are eight steps you must take.

8 Essential Steps of an Organizational Root Cause Analysis

1. identify performance or opportunity gaps.

The first step in a root cause analysis is identifying the most important performance or opportunity gaps facing your team, department, or organization. Performance gaps are the ways in which your organization falls short or fails to deliver on its capabilities; opportunity gaps reflect something new or innovative it can do to create value.

Finding those gaps requires leveraging the “leader as beacon” form of leadership.

“Leaders are called upon to illuminate what's going on outside and around the organization,” Margolis says in Organizational Leadership , “identifying both challenges and opportunities and how they inform the organization's future direction.”

Without those insights, you can’t reap the benefits an effective root cause analysis can produce because external forces—including industry trends, competitors, and the economy—can affect your company’s long-term success.

2. Create an Organizational Challenge Statement

The next step is writing an organizational challenge statement explaining what the gap is and why it’s important. The statement should be three to four sentences and encapsulate the challenge’s essence.

It’s crucial to explain where your organization falls short, what problems that poses, and why it matters. Describe the gap and why you must urgently address it.

A critical responsibility is deciding which gap requires the most attention, then focusing your analysis on it. Concentrating on too many problems at once can dilute positive results.

To prioritize issues, consider which are the most time-sensitive and mission-critical, followed by which can make stakeholders happy.

3. Analyze Findings with Colleagues

It's essential to work with colleagues to gain different perspectives on a problem and its root causes. This involves understanding the problem, gathering information, and developing a comprehensive analysis.

While this can be challenging when you’re a new organizational leader, using the double helix of leadership —the coevolutionary process of executing organizational leadership's responsibilities while developing the capabilities to perform them—can help foster collaboration.

Research shows diverse ideas improve high-level decision-making, which is why you should connect with colleagues with different opinions and expertise to enhance your root cause analysis’s outcome.

4. Formulate Value-Creating Activities

Next, determine what your company must do to address your organizational challenge statement. Establish three to five value-creating activities for your team, department, or organization to close the performance or opportunity gap you’ve identified.

This requires communicating organizational direction —a clear and compelling path forward that ensures stakeholders know and work toward the same goal.

“Setting direction is typically a reciprocal process,” Margolis says in Organizational Leadership . “You don't sit down and decide your direction, nor do you input your analysis of the external context into a formula and solve for a direction. Rather, setting direction is a back-and-forth process; you move between the value you'd like to create for customers, employees, investors, and your grasp of the context.”

5. Identify Necessary Behavior Changes

Once you’ve outlined activities that can provide value to your company, identify the behavior changes needed to address your organizational challenge statement.

“Your detective work throughout your root cause analysis exposes uncomfortable realities about employee competencies, organizational inefficiencies, departmental infighting, and unclear direction from leadership at multiple levels of the company,” Mayo says in Organizational Leadership .

Factors that can affect your company’s long-term success include:

- Ineffective communication skills

- Resistance to change

- Problematic workplace stereotypes

Not all root cause analyses reveal behaviors that must be eliminated. Sometimes you can identify behaviors to enhance or foster internally, such as:

- Collaboration

- Innovative thinking

- Creative problem-solving

6. Implement Behavior Changes

Although behaviors might be easy to pinpoint, putting them into practice can be challenging.

To ensure you implement the right changes, gauge whether they’ll have a positive or negative impact. According to Organizational Leadership , you should consider the following factors:

- Motivation: Do the people at your organization have a personal desire for and commitment to change?

- Competence: Do they have the skills and know-how to implement change effectively?

- Coordination: Are they willing to work collaboratively to enact change?

Based on your answers, decide what behavior changes are plausible for your root cause analysis.

7. Map Root Causes

The next step in your analysis is mapping the root causes you’ve identified to the components of organizational alignment. Doing so helps you determine which components to adjust or change to implement employee behavior changes successfully.

Three root cause categories unrelated to behavior changes are:

- Systems and structures: The formal organization component, including talent management, product development, and budget and accountability systems

- People: Individuals’ profiles and the workforce’s overall composition, including employees’ skills, experience, values, and attitudes

- Culture: The informal, intangible part of your organization, including the norms, values, attitudes, beliefs, preferences, common practices, and habits of its employees

8. Create an Action Plan

Using your findings from the previous steps, create an action plan for addressing your organizational problem’s root cause and consider your role in it.

To make the action plan achievable, ensure you:

- Identify the problem’s root cause

- Create measurable results

- Ensure clear communication among your team

“One useful way to assess your potential impact on the challenge is to understand your locus of control,” Mayo says in Organizational Leadership , “or the extent to which you can personally drive the needed change or improvement.”

The best way to illustrate your control is by using three concentric circles: the innermost circle being full control of resources, the middle circle representing your ability to influence but not control, and the outermost circle alluding to shifts outside both your influence and control.

Consider these circles when implementing your action plan to ensure your goals don’t overreach.

The Importance of Root Cause Analysis in Organizational Leadership

Root cause analysis is a critical organizational leadership skill for effectively addressing problems and driving change. It helps you understand shifting conditions around your company and confirm that your efforts are relevant and sustainable.

As a leader, you must not only effect change but understand why it’s needed. Taking an online course, such as Organizational Leadership , can enable you to gain that knowledge.

Using root cause analysis, you can identify the issues behind your organization’s problems, develop a plan to address them, and make impactful changes.

Are you preparing to transition to a new leadership role? Enroll in our online certificate course Organizational Leadership —one of our leadership and management courses —and learn how to perform an effective root cause analysis to ensure your company’s long-term success. To learn more about what it takes to be an effective leader, download our free leadership e-book .

About the Author

Root Cause Analysis: A Complete Guide With Example (2023)

Root Cause Analysis (RCA) is not just a structured method of problem-solving; it’s a vital component of organisational leadership. The goal of RCA is to fully understand what caused an issue, allowing for effective corrective actions.

One of the first steps in a successful RCA is identifying performance or opportunity gaps within an organisation. These gaps reflect ways in which an organisation falls short or fails to deliver on its capabilities. RCA helps in pinpointing these gaps, thereby allowing for more targeted solutions.

This article will take you through the benefits of RCA and the three basic types of root causes behind workplace incidents. We’ll then explore the two popular methodologies for RCA and how you can use the RCA methodology to identify them.

Finally, we’ll share tools and best practices to help you implement a robust RCA framework so you can develop a comprehensive problem-solving process for safety and risk management in your organisation.

Read on to discover how RCA can revolutionise your approach to problem-solving and risk management.

The benefits of Root Cause Analysis (RCA)

Without a structured RCA framework for resolving incidents, organisations risk implementing superficial quick fixes that may address some of the symptoms but not the core problems.

An effective RCA methodology helps an organisation’s Health & Safety (H&S) team to identify the root causes of a reported incident in the workplace, which is essential to assign effective preventive or corrective actions . Implementing this framework have many benefits:

- Save time, money, and resources because they can identify and invest in the right preventive and corrective actions.

- Prevent the incident from recurring because they can correct the factors causing the issues.

- Prevent more damage or injury caused by a recurring incident.

- Prevent more downtime caused by a recurring incident.

- Boost productivity because they don’t have to revisit the same incident and spend extra time trying to solve the underlying issues.

The three basic types of root cause

There are three fundamental types of root causes:

- Environmental root cause These are causes related to external factors such as moisture levels, weather, or geography.

- Individual root cause These are causes related to an individual’s behaviour, personal choices, ability, or circumstance.

- Organisational root cause These are causes involving internal organisational structure or processes.

The two popular RCA frameworks

A study by Baylor University Medical Center Proceedings identified two popular RCA frameworks. We will cover each one with an example.

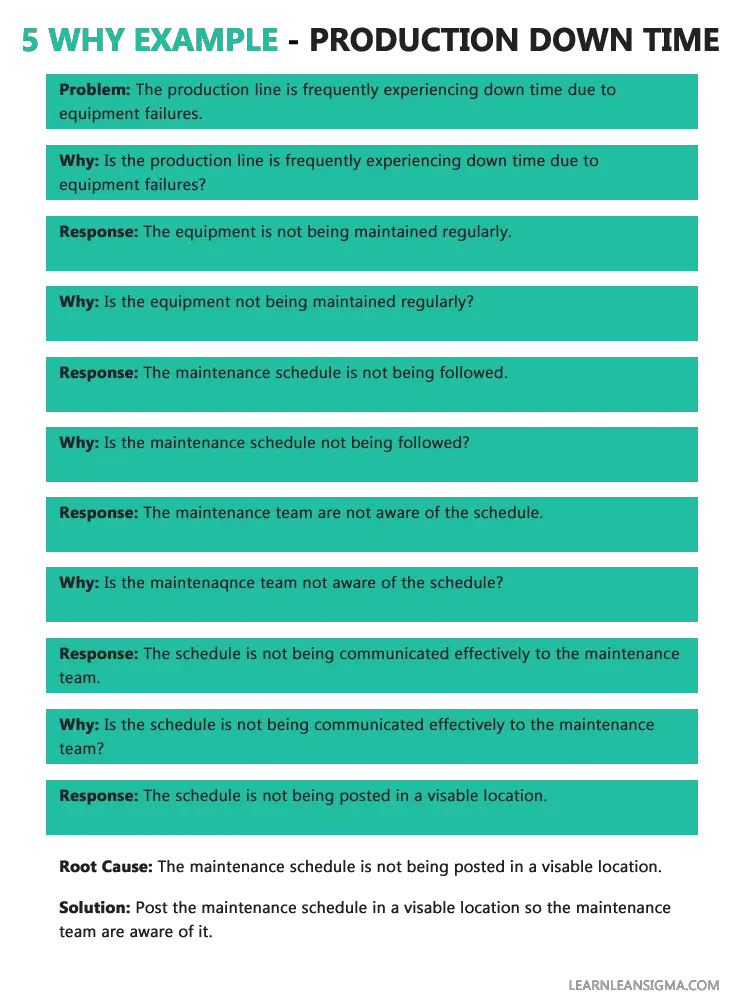

#1: The “5 Whys” Method

This is perhaps the most popular RCA technique because of its simplicity. The method is to ask why something happened at least five times. Here’s an example of how it works.

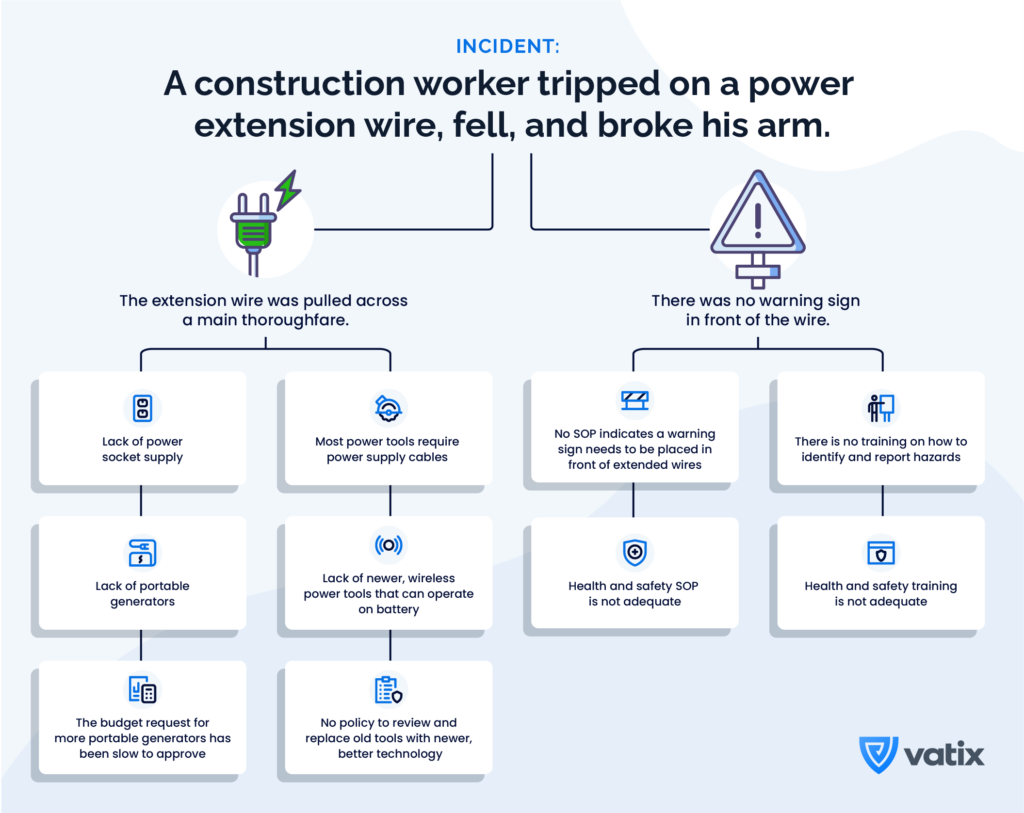

Incident: A construction worker fell and broke his arm.

- “Ask Why” #1: Why did he fall? Answer: He tripped on a wire

- “Ask Why” #2: Why was the wire on the ground? Answer: It was an extension wire needed to supply power to a tool on the other side.

- “Ask Why” #3: Why was the wire pulled across a thoroughfare? Answer: There was no power socket on the other side.

- “Ask Why” #4: Why is there only one power socket in that area? Answer: There aren’t enough portable generators on the site.

- “Ask Why” #5: Why aren’t enough portable generators on the site? Answer: The application requesting the budget to rent a few more portable generators is pending approval.

Using this RCA technique, we’ve identified the actual root cause to be an organisational root cause. The solution for the organisation is to improve the process of approving budgets.

Speeding up the process of approving budgets doesn’t just help prevent future similar incidents. It may also bring the added benefit of improving productivity when construction workers can quickly get what they need to perform their tasks.

Without using this RCA technique, one could have soon concluded that it was solely an environmental or individual root cause. Any corrective actions in these areas are likely to be ineffective or short-term.

#2: Causal Tree

A causal tree is used to evaluate other possible causes that contributed to the incident. This can help organisations identify other possible preventive or corrective actions. Here’s an example of how a causal tree could look like for the same incident example above:

Organisations can explore other possible root causes that need addressing using a causal tree. This RCA methodology is beneficial for identifying root causes across environmental, individual, and organisational categories. Another advantage of using the causal tree framework is that it allows organisations to implement short-term solutions to prevent incidents while they take more time to find answers to more prominent issues. For example, the construction company can implement the short-term solution of placing warning signs in front of extended wires on the ground. Meanwhile, the organisation will look into solving the other root causes identified, such as improving the budget approval process and hazard reporting training.

Common Mistakes to Avoid in Root Cause Analysis

Root Cause Analysis (RCA) can be highly effective in addressing workplace safety issues when done correctly.

However, there are some common mistakes that organisations make when conducting RCA.

Mistake #1: Jumping to conclusions

One of the most common mistakes is jumping to conclusions without thoroughly examining the available information. This often leads to implementing quick fixes that do not address the root cause of the problem.

Tip: Ensure that you take the time to gather all relevant information and systematically work through the RCA process to identify the underlying cause.

Mistake #2: Focusing only on individual errors

Another mistake is solely blaming individuals for incidents without considering the broader organisational context. This can lead to a culture of blame and an unwillingness to report incidents in the future.

Tip: While it is essential to consider individual factors, also examine organisational root causes and environmental factors that may have contributed to the incident. This will help to create a more comprehensive understanding of the issue and lead to more effective solutions.

Mistake #3: Neglecting to involve the right people

One common mistake organisations make is neglecting to involve the right people in the RCA process. A successful RCA requires input from various stakeholders, including employees directly involved in the incident, supervisors, and management. Collaborative analysis helps in collecting a variety of viewpoints and promotes a sense of collective accountability for workplace safety.

Tip: Involving all pertinent stakeholders in the RCA process is crucial, as it aids in collecting a variety of viewpoints and promotes a sense of collective accountability for workplace safety.

Mistake #4: Inadequate documentation

Poor documentation of the RCA process and its outcomes can lead to a lack of accountability and hinder the implementation of corrective actions.

Tip: Document every step of the RCA process, including the incident description, investigation, root cause identification, and proposed corrective actions. This will help ensure that all stakeholders are aware of their responsibilities and can track the progress of the implemented solutions.

Mistake #5: Failing to follow up on corrective actions

Implementing corrective actions is only one part of the RCA process. Organisations sometimes fail to follow up on these actions, which can lead to a recurrence of the incident or issue.

Tip: Establish a system to monitor the progress of corrective actions and evaluate their effectiveness. Regularly review the implemented solutions and make any necessary adjustments to ensure that the root cause is fully addressed and the risk of recurrence is minimised.

How to implement a robust RCA framework

To enhance workplace safety, it is crucial to establish a strong RCA framework within your organisation.

These are the following steps to implement such a framework:

- Train the H&S team on how to use the different types of RCA frameworks.

- Make it easy for employees to report incidents and other events like near misses.

- Update the new employee training, health and safety training, and SOP guides on submitting incident reports and conducting RCA.

- Conduct regular health and safety training sessions.

- Creating an action plan: outline the steps to be taken, the stakeholders involved, and the timeline for implementation

The importance of high-quality incident and hazard reports

The effectiveness of any Root Cause Analysis (RCA) relies heavily on the input data’s accuracy and quality. Therefore, it is imperative to have a reliable incident reporting system in place to ensure the provision of high-quality input data.

Here are the characteristics of a high-quality incident report:

- Records the incident’s time, date, and location.

- Is honest, clear, and concise.

- Provides accurate information that doesn’t leave out important facts.

- Provide as much context as possible.

- It is written in a first-person, objective observation of what happened, not what they think might have happened.

To write an accurate incident report, employees should be encouraged to start writing the report as soon as possible.

Delaying writing the report can lead to inaccurate reports or reports without enough detail because the memory gets fuzzy. Whenever possible or relevant, employees should also attach photos for additional context.

To help you navigate the complexities of incident reporting, we strongly recommend downloading our free checklist and comprehensive guide .

Best practices to improve incident reporting and RCA

One of the best practices to improve the quality of incident reports is digitalising the incident reporting process.

Here’s an example of how Vatix’s incident reporting systems can improve the quality of workplace incident reports and RCA.

- Higher quality incident reports Our mobile platform makes it easy for employees to report an incident from anywhere without the friction of filling out and submitting a paper form. Facilitating on-the-spot reporting for employees minimises the likelihood of postponing or neglecting to report incidents or other events. Faster reporting of incidents also improves the quality of the report. Employees are more likely to record details with better descriptions and upload photos directly from their mobile devices, improving the data needed for an effective RCA.

- Customise incident types to an organisation’s specific needs Our incident reporting software allows organisations to customise the types of incidents employees can report. These templates eliminate the need to print out, distribute, and file multiple forms.

- Easily customise the incident reporting template to capture relevant information. With our incident reporting software, organisations can customise the incident reporting forms to ensure employees submit all required and relevant information.

- Real-time reporting and location tracking for faster response Paper-based incident reporting causes a lot of delays and it can take hours before supervisors or managers can view the incident reports. With real-time mobile incident reporting, employees can submit incidents on-the-spot and the H&S team will be alerted with a location so they can respond to the incident within minutes. In some cases, faster response time with location tagging can be the difference between life and death.

- Easy to get more context at a glance Unlike manual paper-and-pen incident reporting forms, employees can easily add photographs to the incident report directly from their mobile. The incident reporting app also logs the location and provides visual maps for additional context at a glance.

Improve workplace health & safety processes

By combining mobile incident reporting with an effective RCA strategy, organisations can respond to incidents faster and more effectively to create a positive safety culture, leading to increased productivity and decreased risk of accidents and injuries. Talk to our sales here to learn more about how you can customise our mobile incident reporting software to fit your business and improve workplace safety.

Latest posts

Safeguarding Vulnerable Groups Act 2006

Hierarchy of Control: 5 Pillars to Reduce Risk in the Workplace

Martyn’s Law: A Guide to Enhancing Public Security in the UK

Elevate safety & operations with vatix.

How to Perform a Root Cause Analysis (Free Template)

If you’re chronically ill, pain medication will help but not solve the issue. Just like if you’re experiencing abnormally high customer churn , the last thing you want is to spend all your time firefighting.

You need to find the cause.

That’s exactly why root cause analysis is a vital process. It helps you to understand the causal focus and underlying issues behind your biggest business problems.

For example, Eastman Chemical ‘s customer complaint numbers were cut in half after conducting a logic tree root cause analysis to pinpoint their deeper issues. Clipper Windpower saved $1 million in lost revenue by identifying the underlying causes of their turbine malfunction.

In this Process Street article, we have a root cause analysis template for you to follow. Our aim is to give you a comprehensive overview of the root cause analysis process, from a simple introduction and break down of the key principles to when and why you’d want to perform a root cause analysis.

We’ll be covering:

Root cause analysis template

What is root cause analysis (rca), why conduct a root cause analysis, key principles of root cause analysis, how to conduct a root cause analysis that actually works.

- Root cause analysis tips

Using Process Street to conduct a root cause analysis

Let’s take a quick look at the root cause analysis template.

This Root Cause Analysis Template was made in Process Street. Process Street is a BPM software that allows you to build, maintain, and optimize your business processes . This process was built completely from scratch and uses Process Street features like:

- Role assignments (for seamless collaboration)

- Approvals (to ensure work is done properly and to the highest quality)

- Stop tasks (to enforce process adherence and reduce error)

Here are some other checklists you may be interested in:

- SWOT Analysis Template

- FMEA Template: Failure Mode and Effects Analysis

- Gap Analysis Template

- Prioritization Matrix Checklist Template

So, back to root cause analysis. In simple terms, what exactly is a root cause analysis?

Root cause analysis (RCA) involves pinpointing the root cause of problems to be able to find the best solutions for them. This methodology highlights the importance of taking preventative and corrective measures, as opposed to just treating the symptoms of problems, as so often is the case.

There are various techniques and principles that can be used to perform root cause analysis to help identify underlying issues. RCA attempts to look past what may seem like the obvious cause and effect, and help find exactly where systems failed to begin with.

There are generally three goals when conducting a root cause analysis:

- To pinpoint the root cause of a problem

- To gain a full understanding of how to correct the underlying problems

- To implement what was learned to fix the current problem and to prevent it from happening again in the future

The third goal is arguably the most important, because what good is conducting an analysis if nothing is done with the information?

RCA can be used to optimize company processes and set preventative measures to mitigate any future issues. For example, instead of constantly responding to support tickets, you could ask why your customers are making those requests in the first place. Could the onboarding process be improved? Is the product experience confusing? Are you properly educating your customers on how to use your product?

Though treating the symptoms of deeper issues may seem quick and effective at the time, it only leads to future repetition of the same problems. In the long run, you’d save significantly more time and effort by addressing the root cause straight on.

Some of the key principles to keep in mind when conducting a RCA include:

- Make efforts to look past the symptoms to identify the root cause

- Know that there may be more than one root cause

- Don’t focus on who was responsible, focus on why it happened

- Always look for definitive evidence to support the hypothesized root cause

- Gather enough information to devise a plan of action and correct the issues

- Decide how best to prevent similar problems from occurring in the future

These key principles highlight the value of looking at the bigger picture, building context, and taking direct action when addressing systemic issues. Following these principles will ensure your analysis is high quality and offers valuable, actionable results.

So, you’ve decided to conduct a root cause analysis, but don’t know where to begin. There are many techniques and approaches that you can use for this, so we’ll cover some of the most popular methods out there.

The 5 Whys method is one of the most popular techniques used when conducting a root cause analysis. In principle, this method is very straightforward. It entails asking ‘why’ over and over, until the core issues are exposed. On average, it takes five whys until you get to your root cause, but the range varies from company to company and problem to problem.

Stephen Spear has a great example of the 5 Whys process in his book, The High-Velocity Edge: How Market Leaders Leverage Operational Excellence to Beat the Competition :

The scenario is: A vehicle will not start.

First why? Answer: The vehicle’s battery is dead.

Second why? Answer: The alternator isn’t working.

Third why? Answer: The alternator belt is broken.

Fourth why? Answer: The alternator belt was beyond its service life and wasn’t replaced.

Fifth why? Answer: The vehicle hasn’t been maintained according to the recommended service schedule. (Root cause)

In this example we can see that, after these five questions, the root cause of the vehicle’s dead battery is a lack of maintenance. So, to address this issue and mitigate any future problems, all vehicles need to be serviced properly according to their schedules.

The 5 Whys method helps to not jump to conclusions by focusing on digging deeper and deeper until the core answers are revealed. Also, keep in mind, your final answer should lead to actionable conclusions.

Here’s a template we built following the 5 Whys method:

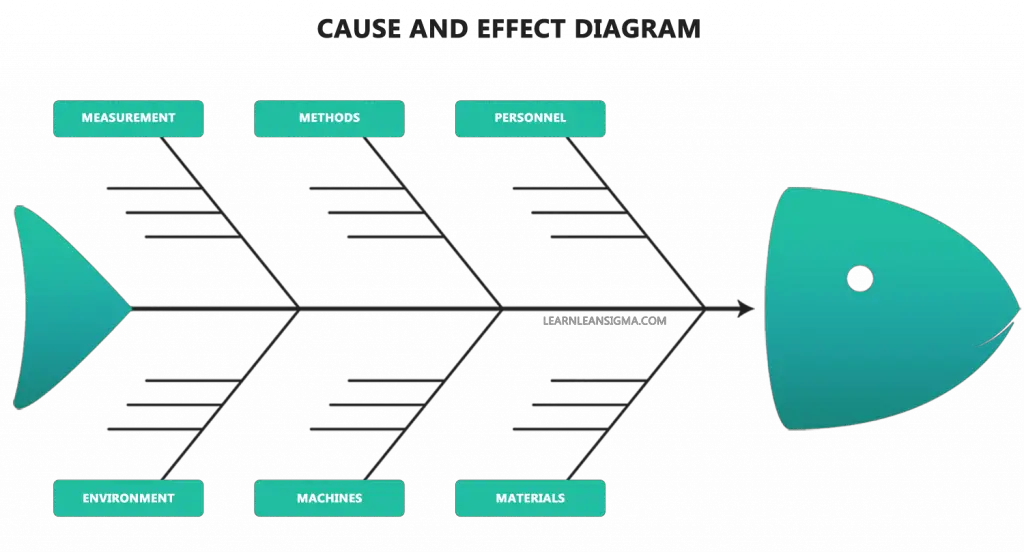

Fishbone diagram

A fishbone diagram, also known as an Ishikawa diagram, is another very popular RCA method. It involves creating a visual cause-and-effect map to help pinpoint root causes by asking you to follow various potential paths until you arrive at the correct one. It’s kind of like a visual representation of the 5 Whys method.

You begin with recording the problem in the center of the diagram (the fish spine), and then jotting down several possible causes for the problem, placing them around the main problem in branches (the fish rib bones). The initial branch categories begin as very broad ideas, such as “environment” or “communication”, and then each of those categories branch out further into smaller, more specific categories. For instance, “communication” may branch out into subcategories like “internal communication tools”, “company communication policies,” or “workplace politics.”

It’s basically using a process of elimination, where you dig deeper and deeper into each potential cause until you arrive at the root cause. This method is more efficient if you take the time to carefully choose your initial categories to better focus on the main problems.

Some commonly used categories in a Fishbone diagram include:

- Physical labor

- Employee expectations

- Product/service

- Maintenance

- Employee performance

- Environment

- Employee skills

These are both examples of continuous improvement. We’ve written a lot about continuous improvement at Process Street. If you’re interested in more relevant resources, then check out these articles:

- What Continuous Improvement Is (and How to Use It)

- Kaizen: How to Deploy Continuous Improvement to Rocket Your Success

- How to Use The Deming Cycle for Continuous Quality Improvement

- What is VRIO? The 4-Step Framework for Continuous Business Success

- Agile ISO: How to Combine Compliance with Rapid Process Improvement

- PDCA: How to Eliminate Error in Your Processes and Products

Tips for an effective root cause analysis

1. ask a lot of questions.

The more questions you ask, the more likely you are to identify the root cause. Continue to ask questions even if you think you’ve arrived at the underlying problem. For example, ask questions like, “How can we be sure this is the root cause and not something else? How can we prevent this from happening again in the future?”

Use these questions to help guide you towards a better understanding of your problem.

2. Work together with others

Sometimes it’s easy to miss something even if it’s right under your nose. If you work with a fellow colleague or a team , it will help identify solutions quicker because you have access to a fresh perspective. They can also offer alternative solutions you may not have thought of on your own.

3. Perfect your root cause analysis with practice

When you’re conducting your root cause analysis, don’t just blindly jump in and run through it. It’s important to be aware of the process as you’re moving through it. Consider what could be changed or improved for next time. Doing this means that your RCAs will be more efficient and effective each time.

4. Conduct a root cause analysis for successes as well

Though RCA is typically used to determine the root cause of problems, it can also be used to identify the root cause of successes. This gives you the tools necessary to be able to intentionally repeat these successes in future or adapt them to other areas of your business to make improvements .

There are a few ways you might perform a root cause analysis. Maybe you have an in-person brainstorming session with a good, ol’ fashioned whiteboard, maybe you knock together a Microsoft Word document which you’ll distribute to your team via print or email, or maybe you use a BPM software like Process Street.

You’ve already seen our Root Cause Analysis Template . Maybe you’ve already signed up for a free Process Street account. If you’re not sure what Process Street is about, check out this quick video:

We mentioned that the Root Cause Analysis Template uses role assignments, approvals , and stop tasks: that’s just the tip of the iceberg. Depending on how complex you want to make your process, you can effortlessly edit the template in this article to include even more functionality, like:

- Conditional logic (for dealing with complex and variable outcomes)

- Dynamic due dates (for time sensitive tasks)

- Automations (to make recurring tasks even more efficient)

Process Street integrates (via Zapier , Webhooks , and API) with 1500+ different apps. So, you can hook up all of your internal processes to the tools you already use on a daily basis. My colleague, Blake, has a great webinar on how to get started (and succeed) with Process Street’s automations:

Check out these related articles for more information on business process management:

- 9 Benefits of Business Process Management (BPM) and Why You’ll Love It

- What is BPM Software? The Best Business Process Management Software (BPMS)

- The Complete Guide to Business Process Management is Here!

- What is Business Process Management? A Really Simple Introduction

- Process Management Explained: How to Combat Poor Processes in Your Business

- Maintenance Management: 6 Steps for Scaled Production and Growth

If you’re wondering about best practices for performing a root cause analysis with Process Street, just drop us a comment below! We’ll be happy to give you tips and help walk you through the process.

Get our posts & product updates earlier by simply subscribing

Oliver Peterson

Oliver Peterson is a content writer for Process Street with an interest in systems and processes, attempting to use them as tools for taking apart problems and gaining insight into building robust, lasting solutions.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

Guide: Root Cause Analysis

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

Root Cause Analysis (RCA) is a key tool in continuous improvement, acting as a systematic approach to identify and tackle the underlying issues behind problems. RCA aims not only to provide a temporary fix but to offer long-lasting solutions by addressing the root causes.

RCA, such as the Fishbone Diagram , the 5 Whys , and FMEA . Whether you’re looking to solve complex challenges or improve cost-efficiency, this guide will offer understanding of how to identify the root cause of problems with useful Lean Six Sigma tools.

What is Root Cause Analysis?

Root Cause Analysis, often referred to as RCA, is like being a detective for problems in your business or project. Imagine you have a leaking pipe in your house. You could keep mopping up the water every time it leaks, but that’s not really solving the issue. The right thing to do is find out why it’s leaking in the first place and fix that. RCA works the same way; it helps you find out the “why” behind a problem so you can fix it for good.

Structured Approach

When we say RCA is a “structured approach,” we mean it’s not just random guesswork. It’s a planned way to dig deep into a problem. You will follow certain steps and use specific tools to figure out what’s really going on. This makes sure you’re not just treating the “symptoms” of the problem, like mopping up water from a leak, but you’re finding out why the problem is happening in the first place.

Identify Underlying Reasons

The “underlying reasons” are the real culprits behind a problem. For example, if a machine in a factory keeps breaking down, simply repairing it each time isn’t enough. You need to find out why it’s breaking down. Is it old? Are people using it wrong? RCA helps you answer these kinds of questions.

Long-term Solutions

The coolest part about RCA is that it’s focused on long-term solutions. Once you know the root cause of a problem, you can create a fix that will (hopefully) make sure it never happens again. This is way better than just putting out fires all the time.

By understanding and using RCA, you’re not just stopping at “What is the problem?” You’re going the extra mile to ask, “Why did this problem happen?” and “How can we make sure it doesn’t happen again?” That’s a game-changer in making things better for the long run.

Importance of Root Cause Analysis

Understanding the “why” behind a problem isn’t just something that’s nice to do; it’s crucial for several reasons.

Problem Solving

Imagine you have a puzzle, but all the pieces are jumbled up. Trying to see the whole picture from this mess would be overwhelming, right? RCA is like sorting these puzzle pieces into groups; maybe by color or edge pieces versus middle pieces. When you break down a big, complex problem into smaller parts, it becomes much easier to solve. RCA helps you dissect a problem into its basic elements so you can tackle each one individually. This makes it easier to find out what’s really going wrong and fix it.

Cost-Efficiency

You know the saying, “Time is money”? Well, constantly fixing the same problem over and over again is like throwing both time and money down the drain. If you use RCA to get to the bottom of an issue and solve it at its root, that issue is less likely to come back. This means you spend less time, effort, and money on it in the future. For a business, this is a big deal because it means you can focus on growing and improving, rather than fixing the same old problems. This is where most businesses fail to progress as they spend the day to day activities fire fighting repreated problems.

Quality Improvement

Let’s say you run a bakery, and you notice that your chocolate chip cookies are coming out burnt too often. You could just toss the burnt cookies and make a new batch, but that doesn’t stop the next batch from burning too. If you use RCA to find out why they’re burning—maybe the oven temperature is wrong or the baking time is too long—you can fix that issue and make perfect cookies every time. This makes your customers happy and keeps them coming back. In the same way, RCA helps you improve the quality of your products or services by fixing the real issues, not just the symptoms. This leads to happier customers and better reviews, which are good for any business.

Types of Root Cause Analysis Methods

When it comes to finding the real reason behind a problem, one size doesn’t fit all. Different situations may require different approaches. That’s why there are several methods for conducting RCA. Let’s explore three of the most commonly used methods.

Fishbone Diagram (Ishikawa)

Imagine a fish. The head represents the problem you’re facing, and the bones branching off from the fish’s spine are the possible causes of the problem. This is what a Fishbone Diagram looks like. Also known as an Ishikawa Diagram or Cause and Effect Diagram, this method helps you visually break down a problem into different categories or “themes.”

For example, if you’re running a restaurant and customers are complaining about long wait times, you could use a Fishbone Diagram to categorize potential causes into themes like ‘Staffing,’ ‘Kitchen Efficiency,’ ‘Order Process,’ etc. Within each theme, you list out possible root causes. This helps you see the whole picture and makes it easier to identify where the real issue might be coming from.

You can learn more about the fishbone diagram process with our guide

Remember being a curious kid and asking “Why?” about everything? The 5 Whys method is pretty much the same. Start with the problem at hand and ask “Why did this happen?” Once you have an answer, ask “Why?” again, digging deeper. Keep asking “Why?” until you’ve asked it five times or until you reach a point where the root cause becomes clear.

For example, if a machine in a factory stops working, you could ask:

- Why did the machine stop? (Answer: The motor burned out.)

- Why did the motor burn out? (Answer: The motor was overloaded.)

- Why was the motor overloaded? (Answer: The machine was running at high capacity for too long.)

- Why was the machine running at high capacity for so long? (Answer: There was a backlog of orders.)

- Why was there a backlog of orders? (Root Cause: Poor planning and scheduling.)

- This helps you trace back the chain of events to find the root cause of the problem.

You can learn more about the 5 Whys process with our guide.

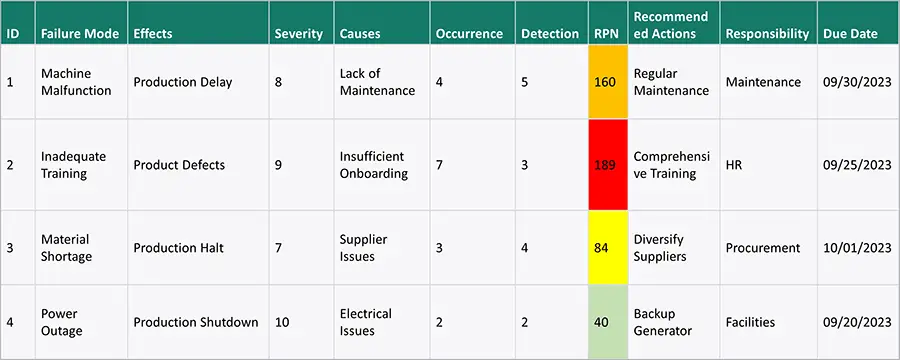

FMEA (Failure Modes and Effects Analysis)

FMEA is like looking into a crystal ball to see what could go wrong in the future. It’s a way to evaluate different ways a process or product could fail and to understand the impact of those failures. You list out all possible failure modes, how likely they are to happen, how bad the impact would be, and how well you could detect them before they cause problems. This helps you prioritize which potential issues need immediate attention.

Below is an example from a manufacturing business. The higher the RPN (risk priority number) the more important it is to address the issue.

You can learn more about the FMEA with our guide

Selecting an RCA method

If you are new to root cause analysis it can be difficult knowing which approach to use to solve your problem. This can be made simpler by considering the below

Is the problem simple and straightforward?

Use The 5 Whys Method

Is the problem complex with multiple factors?

Use Fishbone Diagram (Ishikawa)

Is a quantitative risk assessment needed?

Use FMEA (Failure Modes and Effects Analysis)

Use other specialized RCA techniques or hybrid methods

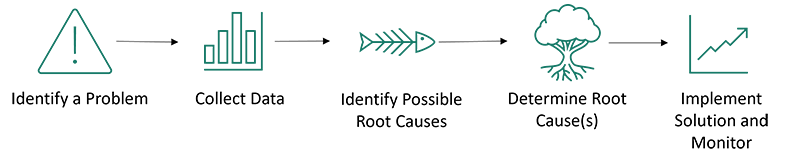

The Five-Step RCA Process

RCA isn’t something you can do haphazardly; it requires a structured approach to be effective. That’s where the Five-Step RCA Process comes in handy. It provides a roadmap to tackle your problem methodically. Let’s start by discussing the first step in detail.

Step 1: Define the Problem

Before you can find a solution to any problem, you need to know exactly what that problem is. You’d be surprised how often people jump to fixing things without clearly understanding what’s wrong in the first place. Defining the problem is like setting the GPS before going on a trip; it sets the direction for everything that follows. Here’s how to go about it:

Be Specific

Let’s say you’re running a coffee shop, and you notice that customers aren’t coming back. Simply saying, “Business is slow,” is too vague. A more specific problem statement would be, “Customer return rate has dropped by 20% in the last two months.”

Numbers don’t lie. Whenever possible, use data to define your problem. In the coffee shop example, you could look at sales records, customer surveys, or loyalty program participation to pinpoint the decline.

Consider the 5 Ws

- Who: Who is affected by this problem? Is it just one department, the whole company, or maybe your customers?

- What: What exactly is the issue? Try to describe it in one sentence.

- Where: Where is this problem occurring? Is it in a specific location or across various places?

- When: When did you first notice this problem? Is it a constant issue or does it happen only at certain times?

- Why: At this stage, you may not know the root cause, but you might have some initial thoughts on why the problem might be occurring.

Write it Down

Once you’ve gathered all this information, write down your problem statement. This serves as a reference point for everyone involved in the RCA process, making sure everyone is on the same page.

After gathering all the relevant information, the problem statement for RCA could be:

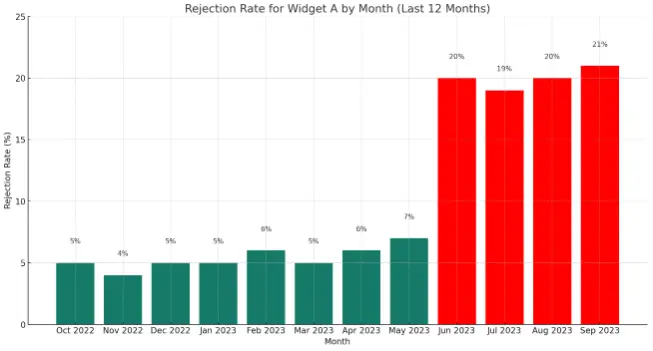

“The rejection rate for Widget A produced on Line 3 has increased by 15% in Q2 2023 compared to Q1 2023, predominantly due to ‘Cracked Surface’ defects. This issue first became apparent at the beginning of Q2 and has been consistent since. Initial observations suggest it may be due to material quality or machine calibration issues.”

Step 2: Gather Data

Once you’ve clearly defined the problem, the next step is like being a detective gathering clues. You’ll need to collect all the relevant information that will help you get to the bottom of the issue. This stage is crucial because the quality of your Root Cause Analysis depends on the quality of your data. Here’s how to go about it:

Identify Data Sources

First, figure out where you can get the information you need. This could be anything from company records and employee interviews to customer surveys and machine logs. For example, if your problem is a decrease in product quality, you might look at manufacturing data, quality control reports, and customer feedback.

Types of Data to Collect

- Quantitative Data : These are numerical data that can be measured. Examples include sales figures, production rates, and customer satisfaction scores.

- Qualitative Data : These are descriptive data that can be observed but not measured. Examples include employee morale, customer comments, and the observable state of machinery or processes.

Timing Matters

When did the problem start? Was it gradual or sudden? Understanding the timeline can offer important insights into potential causes. Collect historical data if possible, as this will help you see trends and patterns.

Use Tools to Collect Data

Depending on your needs, various tools can help in data collection. Spreadsheets can be useful for tracking numbers and metrics. Surveys and questionnaires can capture customer or employee feedback. Advanced organizations may use specialized software for data collection and analysis.

Document Everything

Make sure to keep a record of all the data you collect. Organize the data in a way that’s easy to understand and analyze. Charts, graphs, or tables can be helpful here.

Verify Your Data

Before you move on to analyzing the data, make sure it’s accurate and reliable. Double-check your numbers, verify survey results, and confirm any observations. The last thing you want is to make important decisions based on faulty information.

Gathering data might seem like a time-consuming step, but it’s essential for a successful Root Cause Analysis. The more thorough you are at this stage, the easier it will be to identify the actual root cause of the problem later on.

Example Collected Data

Here’s a snapshot of what some of the collected data could look like:

Machine Logs (June 2023)

| Date | Temperature (°C) | Pressure (psi) | Cycle Time (s) |

|---|---|---|---|

| June 1 | 200 | 1200 | 60 |

| June 15 | 205 | 1210 | 61 |

| June 30 | 210 | 1220 | 62 |

Quality Control Reports (June 2023)

| Date | Defect Type | Count |

|---|---|---|

| June 1 | Cracked Surface | 12 |

| June 15 | Cracked Surface | 20 |

| June 30 | Cracked Surface | 25 |

Employee Interviews

- Operators have noticed the machine making unusual noises.

- Quality control staff report an increase in defects that look like cracks on the surface.

Step 3: Identify Possible Causes

After you’ve defined your problem and collected all the relevant data, it’s time to roll up your sleeves and dig into the “why” behind the issue. This step is like brainstorming, but more structured. You’re trying to come up with a list of all the things that could possibly be causing the problem you’ve identified. Here’s how to do it:

Choose a Method

As mentioned earlier, there are various methods you can use to identify possible causes. Two of the most common are the Fishbone Diagram and the 5 Whys. The choice depends on the nature of your problem.

- Fishbone Diagram: This is good for complex problems where multiple factors could be at play. The diagram allows you to visually organize potential causes into different categories, making it easier to focus your investigation.

- The 5 Whys: This method is more straightforward and works well for simpler problems. By repeatedly asking “Why?” you dig deeper into the issue until you identify possible root causes.

Involve the Right People

Don’t try to do this all on your own. Involve team members who are familiar with the problem area. They can offer valuable insights you might not have considered. If you’re dealing with a technical issue, for instance, having an engineer in the room can be incredibly helpful.

Generate a List of Possible Causes

Using your chosen method, start listing down all the potential causes. Be as comprehensive as possible. If you’re using a Fishbone Diagram, for instance, you’d list potential causes under each category or “bone” of the fish. For the 5 Whys, you’d document the chain of reasoning that leads you to potential root causes.

Use Your Data

Remember the data you collected in Step 2? Now’s the time to use it. Align your list of possible causes with the data to see which ones are most likely. For example, if one of your potential causes is “Poor Training,” but your data shows that all employees have completed mandatory training, then you might want to reconsider that cause.

Prioritize Causes

Not all causes are created equal. Some are more likely than others to be the root cause of your problem. Use your team’s expertise and the data you’ve collected to prioritize which causes to investigate further.

By the end of this step, you should have a well-organized list of possible causes for your problem, backed by data and expert input. This sets the stage for the next steps, where you’ll zero in on the actual root cause and figure out how to fix it.

Example of Identifying Possible causes

Following on with the same example, as this is a more complex issue with multiple factors, it makes sense to conduct the root cause analysis using the Fishbone method. Therefore, we need to ensure to include the right people—a cross-functional team. In this case, that would comprise production engineers who understand the machinery, quality control experts who have the data on defects, and machine operators who can provide firsthand experience and observations.

The next step is to collectively brainstorm and categorize potential causes for the increased rejection rate in Widget A. Utilizing the Fishbone Diagram, the team breaks down the problem into six major categories: Machine, Method, Material, Manpower, Environment, and Measurement.

Identifying the possible causes in our example

Following on with the same example, as this is a more complex issue with multiple factors, it makes sense to conduct the root cause analysis using the Fishbone method. Therefore, we need to ensure to include the right people—a cross-functional team. In this case, that would comprise production engineers who understand the machinery, quality control experts who have the data on defects, and machine operators who can provide firsthand experience and observations. The next step is to collectively brainstorm and categorize potential causes for the increased rejection rate in Widget A. Utilizing the Fishbone Diagram, the team breaks down the problem into six major categories: Machine, Method, Material, Manpower, Environment, and Measurement.

Step 4: Determine the Root Cause

After identifying a list of possible causes, it’s time to put on your detective hat again and figure out which one is the real culprit—the root cause of your problem.

This is a critical step, as identifying the wrong cause can lead you down a path of ineffective solutions. Here’s how to go about it:

Review Your List of Possible Causes

Start by revisiting the list you made in the previous step. This will serve as your “suspect list” in identifying the root cause. At this point, you’ve already done some initial prioritization, so you have an idea of which causes are most likely.

Analyze the Data

Remember the data you collected in Step 2? Now is the time to dive deep into it. Compare each possible cause against the data to see if it holds up. Look for patterns, correlations, or anomalies that might point to one cause over the others.

For example, if you’re dealing with a decrease in product quality and one of your possible causes is “Faulty Raw Materials,” you could look at inspection reports, batch numbers, and supplier records to see if there’s a correlation.

Conduct Tests or Experiments

Sometimes, analyzing existing data isn’t enough. You might need to conduct additional tests or experiments to validate or rule out possible causes. For instance, if you suspect a machine is malfunctioning and causing a problem, you might run it under controlled conditions to see if the issue repeats.

Use Logical Reasoning

Sometimes the root cause isn’t obvious, even with data and testing. In such cases, logical reasoning can help. You might use deductive reasoning to rule out unlikely causes or inductive reasoning to generalize from specific observations.

Involve Experts

If you’re stuck or the root cause isn’t clear, don’t hesitate to consult experts. These could be internal team members with specific expertise or external consultants who specialize in the problem area you’re investigating.

Confirm the Root Cause

Before you move on to finding a solution, make sure you’ve found the real root cause and not just a symptom of a deeper issue. Validate your findings by asking:

- Does this cause explain most or all of the problem?

- If we fix this, is it likely that the problem will be solved?

- Do most team members agree that this is the root cause?

Once you’ve determined the root cause, document it clearly. You’ll use this information in the next step to develop and implement a solution that addresses the issue at its core, ensuring it’s less likely to recur in the future.

Determining the Root Cause of our Example

Continuing with our example, the cross-functional team now shifts its focus to determining the root cause of the increased rejection rate for Widget A. Armed with their prioritized list of possible causes and the data gathered, they delve into the next step of the RCA process.

The team begins by revisiting the “suspect list” generated using the Fishbone Diagram. Machine-related factors, particularly temperature fluctuations, pressure inconsistencies, and cycle time variability, are at the top of this list, followed by material quality concerns. Analyze the Data Digging deeper into the data collected, the team finds that the temperature, pressure, and cycle time increases directly correlate with the spike in the ‘Cracked Surface’ defect type. They also note that the unusual noises observed by machine operators started to occur around the same time the defects increased. Conduct Tests or Experiments To validate these observations, the team decides to run the molding machine under controlled conditions, varying one parameter at a time while keeping the others constant. After a series of tests, they discover that an increase in temperature directly leads to the ‘Cracked Surface’ defects in the widgets. Use Logical Reasoning Using deductive reasoning, the team rules out other possible causes. For instance, since all operators have completed mandatory training and the material batches show no signs of contamination, these are less likely to be the root causes. Confirm the Root Cause After careful consideration and validation, the team reaches a consensus that the root cause of the problem is “Temperature Fluctuations in the Molding Machine.” This conclusion satisfies the criteria for root cause identification: It explains most, if not all, of the ‘Cracked Surface’ defects. Fixing this issue is likely to resolve the problem. Most team members agree that this is the root cause. The team documents this root cause clearly and prepares for the next step in the RCA process: developing and implementing a solution that will fix this issue at its core, thereby preventing its recurrence in the future.

Step 5: Implement and Monitor Solutions

Congratulations, you’ve identified the root cause! But your journey doesn’t end here. The whole point of Root Cause Analysis (RCA) is to not just find the root cause but to fix it so the problem doesn’t happen again. This is where Step 5 comes in, where you implement solutions and make sure they actually work. Here’s how to go about it:

Develop a Solution Plan

The first thing you need to do is come up with a plan for how you’re going to fix the root cause you’ve identified. This should include:

- What needs to be done: The specific actions that will address the root cause.

- Who will do it: The people responsible for each action.

- When it will be done: A timeline for implementation.

- How it will be done: The resources and methods needed to implement the solution.

Gain Approval and Support

Before you start making changes, make sure you have the necessary approvals. This might mean getting a budget approved or getting buy-in from key stakeholders. The more support you have, the smoother the implementation process will be.

Implement the Solution

Now it’s time to roll up your sleeves and get to work. Follow the plan you’ve developed, and start implementing the solution. This could involve anything from retraining staff and revising procedures to repairing equipment or introducing new technology.

Monitor Effectiveness

You can’t just implement a solution and walk away. You need to monitor how well it’s working. This means going back to the data you collected in Step 2 and continuing to track those metrics. Are they showing improvement? If not, you may need to revisit your solution or even go back to earlier steps in the RCA process.

Make Adjustments as Needed

Sometimes a solution that looks great on paper doesn’t work out as well in the real world. If you find that your solution isn’t as effective as you’d hoped, be prepared to make adjustments. This could mean tweaking your current solution or going back to the drawing board to identify a different root cause.

Document the Process

Don’t forget to document everything you’ve done, from the solutions you implemented to the results you achieved. This documentation can be invaluable for future problem-solving efforts and for creating a knowledge base that can help prevent similar problems in the future.

Implementing and monitoring solutions of our example

After identifying “Temperature Fluctuations in the Molding Machine” as the root cause, the team crafts a detailed solution plan: What Needs to Be Done : Overhaul the machine’s cooling system and recalibrate temperature settings. Who Will Do It : A dedicated team of production engineers and machine operators. When It Will Be Done : To be completed within a two-week timeframe. How It Will Be Done : Allocate necessary resources like new cooling components and software for recalibration.

| Task | Responsible | Timeline | Resources Needed | Status |

|---|---|---|---|---|

| Overhaul cooling system | Production Engineers | Week 1 | Cooling components, tools | To be started |

| Recalibrate temperature settings | Production Engineers | Week 1-2 | Calibration software, tools | To be started |

| Conduct a pilot run | Machine Operators | Week 2 | Test materials | To be started |

Gain Approval and Support Before proceeding, the team prepares a budget proposal and secures approval from management. They also consult with the quality control team and machine operators to gain their buy-in, ensuring a smoother implementation process. Implement the Solution The team then sets out to execute the plan. The cooling system is overhauled, and the machine is recalibrated. A pilot run is conducted to ensure that the new settings are effective in maintaining consistent temperature levels. Monitor Effectiveness After implementing the changes, the team goes back to the data. They continue to monitor the same metrics—temperature, pressure, cycle time, and defect count. Initial results show a significant reduction in the ‘Cracked Surface’ defect type. The temperature fluctuations have notably decreased. Make Adjustments as Needed While the initial results are promising, the team remains vigilant. They agree to meet bi-weekly to review the data and make any necessary adjustments to the solution. So far, no further modifications are required. Document the Process The entire RCA process, from problem identification to solution implementation and monitoring, is meticulously documented. This documentation will serve as a valuable resource for future troubleshooting and continuous improvement initiatives. By diligently following this five-step RCA process, the team has not only identified the root cause of the problem but has also successfully implemented a solution to prevent its recurrence.

RCA is more than just a problem-solving method; it’s a strategic approach that dives deep into issues to eliminate them at their source. By following the Five-Step RCA Process, organizations can not only identify the real culprits behind their problems but also develop and implement long-lasting solutions. This guide walked you through each step in detail, from defining the problem to monitoring the effectiveness of your solutions. Remember, the quality of your RCA is as good as the effort and attention to detail you put into it. Whether you’re looking to improve product quality, enhance customer satisfaction, or increase cost-efficiency, a well-executed RCA can be a game-changing tool in your continuous improvement arsenal. It’s not just about fixing what’s broken; it’s about building something better for the long term.

- Williams, P.M., 2001, April. Techniques for root cause analysis . In Baylor University Medical Center Proceedings (Vol. 14, No. 2, pp. 154-157). Taylor & Francis.

- Gangidi, P., 2018. A systematic approach to root cause analysis using 3× 5 why’s technique. International Journal of Lean Six Sigma , 10 (1), pp.295-310.

- Wong, K.C., Woo, K.Z. and Woo, K.H., 2016. Ishikawa diagram. Quality Improvement in Behavioral Health , pp.119-132.

Q: Why is Root Cause Analysis important?

A: Identifying and resolving the root cause of an issue is crucial for achieving sustainable improvements. Focusing only on symptoms can lead to temporary fixes that may mask the underlying problem. RCA helps you understand the systemic issues contributing to a problem, allowing you to put in place measures that result in lasting change.

Q: What are the common methods used for Root Cause Analysis?

A: Several methods are commonly used for Root Cause Analysis, including:

- 5 Whys : A simple technique that involves asking “why” multiple times until the root cause is identified.

- Fishbone Diagram (Ishikawa Diagram) : A visual tool used to categorize potential causes of a problem.

- Fault Tree Analysis : A graphical representation of various probable causes of an issue, arranged in a hierarchical manner.

- Pareto Analysis : Identifying the most significant factors contributing to a problem based on the Pareto principle.

- FMEA (Failure Modes and Effects Analysis) : A structured approach to identifying potential failure modes and their consequences.

Q: How do I start a Root Cause Analysis?

A: Initiating a Root Cause Analysis typically involves the following steps:

- Define the Problem : Clearly articulate what the issue is.

- Collect Data : Gather relevant information and evidence.

- Identify Possible Causes : List potential causes that could be contributing to the problem.

- Analyze : Use RCA methods like the 5 Whys or Fishbone Diagram to dig deeper.

- Identify Root Cause(s) : Through analysis, pinpoint the underlying cause(s).

- Develop and Implement Solutions : Create action plans to address the root cause(s).

- Review : Evaluate the effectiveness of the solutions and make adjustments as needed.

Q: Can Root Cause Analysis be applied to non-manufacturing sectors?

A: Absolutely, Root Cause Analysis is a versatile tool that can be applied in various sectors, including healthcare, IT, logistics, and even the public sector. The principles remain the same: identify the root cause to implement effective, long-term solutions.

Q: What are some common pitfalls to avoid in Root Cause Analysis?

A: Some common pitfalls to be aware of include:

- Rushing the Process : Skipping steps or rushing through them can lead to incorrect conclusions.

- Blaming Individuals : RCA should focus on systemic issues rather than blaming individual employees.

- Ignoring Data : Failing to consult data can result in assumptions that may not be accurate.

- Lack of Follow-Up : Without proper evaluation and adjustment, even good solutions may fail over time.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website www.learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Was this helpful?

Advisory boards aren’t only for executives. Join the LogRocket Content Advisory Board today →

- Product Management

- Solve User-Reported Issues

- Find Issues Faster

- Optimize Conversion and Adoption

Better problem solving with root cause analysis (with template)

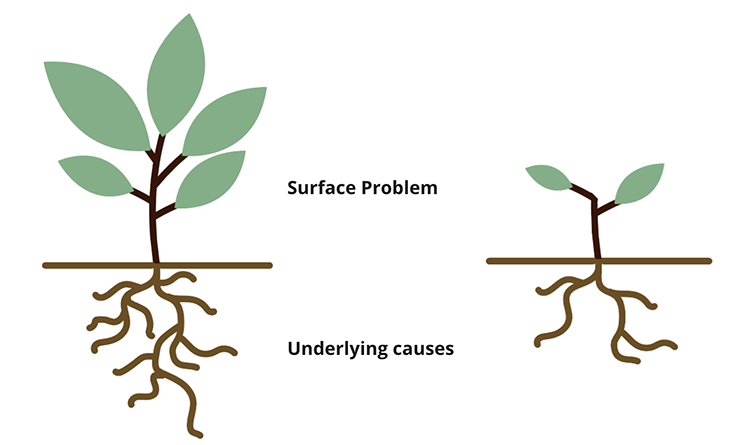

If you walk into your kitchen to find your favorite vase smashed on the floor, it might be safe to assume that the grinning cat nearby was the root cause of this problem. If only it was this simple in business and we could just say “the cat did it.” Product problems are often much more complex and connected to a variety of root causes.

If you think of a weed, the surface is only the problem you can immediately see. However, if you cut the weed from the ground level, it’s likely to grow back from the root. This is just like fixing product problems with a band-aid with little to no investigation of a root cause — it’s likely to return.

These types of problems need a more thorough root cause analysis (RCA) to determine how, and why the problem happened, and how to prevent it in the future.

What is root cause analysis?

Root cause analysis is a tool you can utilize when determining the true cause of a problem. You might have assumptions about what the cause of a problem might be or experience biases towards one as the main cause.

Performing a root cause analysis can help you determine what the underlying causes of a problem are to help address a more impactful and valuable solution:

What are the 4 steps in a root cause analysis?

When you’re trying to uncover the roots of a problem, it can be daunting to figure out where to start. The process to conduct a root cause analysis can be broken down into a few easy steps:

- Define the problem

- Identify and map the problem causes

- Identify the evidence that supports your causes

- Create a root cause analysis report and set up your action plan

1. Define the problem

A clear definition of the problem is the first step. Sometimes problems are easy to identify, like a broken link. More often, problems can be abstract and need clarification, like a decrease in overall purchases through a site or an increase in bugs reported.

Here are some more examples of problems:

- A 20 percent drop in customer purchases placed from the shopping cart page from the previous week

- 60 percent of customers on hold end up dropping their call and, as a result, the company has experienced a decrease in NPS scores

- A 40 percent increase of customer reported issues with using the folders feature in a CRM

- A 15 percent decrease in user engagement with a core feature on a social media site

It’s also critical to understand how to define a problem:

| Evaluate the urgency | Is this a currently existing issue? Could it become a larger problem? Has this problem occurred before and could it happen again? |

| Describe the impact | How does this impact the business? How do the numbers compare to the baseline? What are some of the unintended consequences of this problem? A business with seasonal needs, such as tax preparation products, will see an increase in their average number of customer service calls during tax season. If not prepared for an increase in call volume, they could experience an increase of customer dropped calls, lower NPS scores, and a big impact to their overall business success. |

| Collect evidence | , usage data, and anything that might highlight the problem. Talk with stakeholders, and, if possible, users who are directly impacted by the problem. Sometimes, you might hear of a “huge” problem from a user only to find out that the impact is quite small overall from data evidence. Collecting evidence to evaluate the impact is a crucial step to ensure you’re not over or under reacting to a problem. See more about data collection below to learn about common key metrics in a RCA. |

2. Identify and map the problem causes

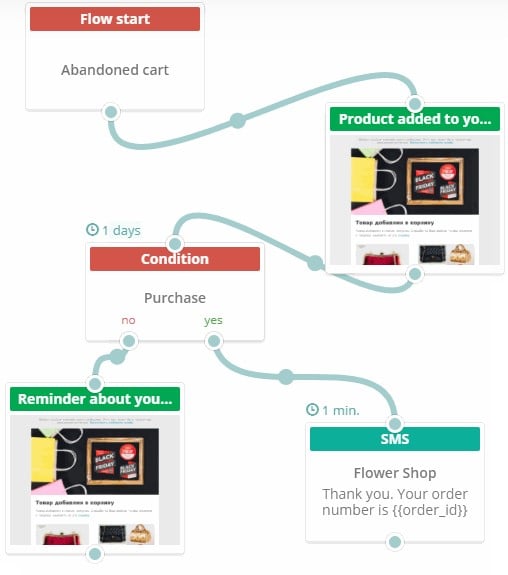

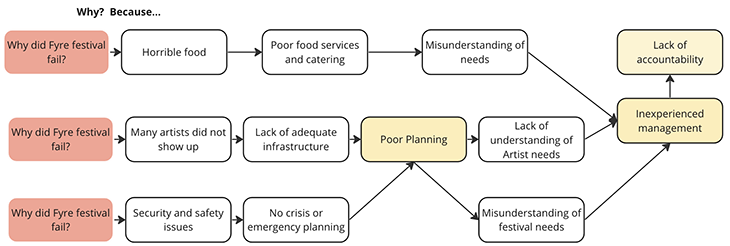

Using tools like a fishbone analysis and the Five Whys framework can help you put together causes and start to categorize themes of the problem. When going through a Five Whys diagram, try to come up with a few alternate pathways and you might notice overlapping areas.

Each example of a Five Whys diagram is accurate, but only looking at one cause can prevent you from understanding the fuller picture. For example, there was more than one reason why the Fyre Festival failed and it’s important to identify overlapping themes to avoid leaning on only one cause:

In a product example, there might be numerous reasons why session times have decreased, or user reported bugs are up.

After evaluating the size, impact, general cause themes, and urgency of the problem, you’ll have a better understanding of how much effort will be needed for the analysis. The larger the problem on the surface, the more underlying causes you might find. Even simple problems can sometimes have numerous causes to consider and you need to determine how in-depth you need to dig to “unroot” the causes.

It’s also critical to check all your bases. Once you have evaluated and categorized the different potential causes to a problem, use the following as a checklist to ensure you’re covering all areas of where and how this problem happened. Be sure to identify any changes or recent events that might have occurred that could have impacted the problem.

- Demographics : is the problem happening to one specific demographic? Only happening to iPhone users? Users in a specific location?

- Time specific : when did the problem happen? Is it continuing to happen? Did the problem only occur during a specific time? You might discover that the problem is related to a time-specific cause, like a release or outage

- User journey : did anything change within the user journey? Map the workflow to determine if any new developments have occurred

- External factors : is this an issue with a third party integration? Did a competitor launch a successful new feature that might be taking business from you? Some of these external factors could be out of your control, but important to recognize

- Internal factors : how many feature releases happened during this time frame? Was there any product downtime or maintenance at that time?

3. Identify the evidence that supports your causes

Collecting evidence is a key part of a root cause analysis. Without evidence, your problem causes are based on assumptions and potentially harmful biases.

Start evaluating any data you might have available. Using session replay tools like LogRocket can help you collect evidence of the problem. Here are a couple of examples of the type of data that can be used to collect evidence:

- User count — number of users impacted by the problem

- Usage — daily, weekly, or monthly active users and a decrease or increase in session time

- Decrease or increase in events — for example, a decrease in users selecting the Add to cart button from a page or an increase in error pages

- Error tracking and user frustration — tools like LogRocket can help track where things are going wrong in your product and surface critical issues

- Qualitative evidence — run user interviews or user-submitted feedback with tools like Loom. Are multiple users running into the same roadblock? Are you seeing the same complaint from multiple users in feedback tickets?

4. Create a root cause analysis report and set up your action plan

Collect your evidence and root cause evaluation into an RCA template. Once you have your causes identified and your discovery efforts into one root cause analysis report, you can start creating a plan to address the problem and prevent it from happening in the future.

Over 200k developers and product managers use LogRocket to create better digital experiences

Collaborate with a team to brainstorm solutions and discuss which options might address multiple causes. Evaluate if you need both a short-term and long-term solution, depending on the level of effort and urgency required. As part of your analysis report, discuss how you can avoid this problem again in the future and any other risk mitigation plans.

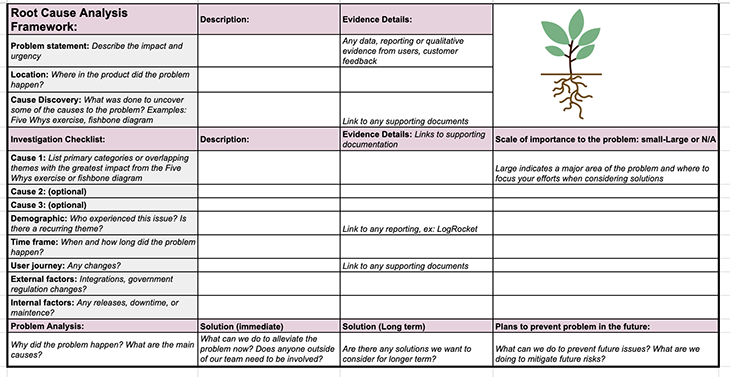

Root cause analysis template

You can use this root cause analysis template on Google Sheets to organization your investigation, collect your evidence, and share with your team to determine next step solutions:

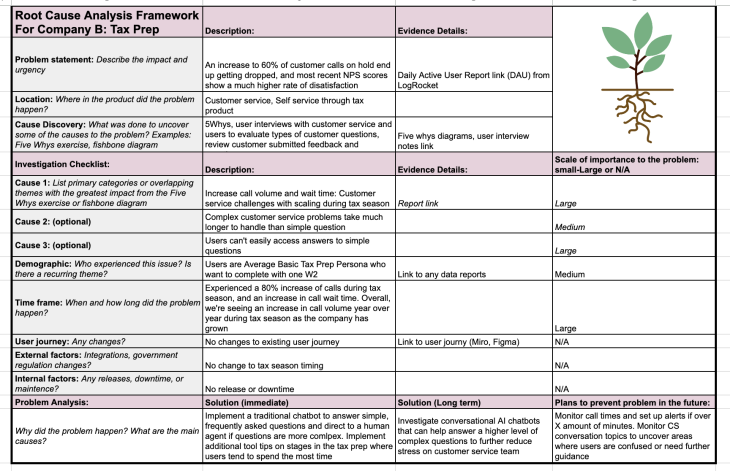

Root cause analysis example

Below is an RCA for Company B, a tax preparation product that experienced an increase in dropped customer calls.

Company B experienced an increase of 60 percent of customers on hold that ended up dropping their call. They also experienced an increase in NPS dissatisfaction and have concerns about losing customers.

After going through a root cause analysis, they discovered an 80 percent increase in user calls during tax season. This increase of call volume indicated much longer wait times to speak to a live agent.

After investigating some of the customer call reasons, they discovered that numerous customers had simple questions that could be answered quickly without too much support.

Company B gathered call logs that confirmed their suspicions. They brought the logs together that demonstrated the simplicity of repeated questions and gathered records of customers that dropped off after a certain amount of time on the phone.

Company B implemented a conversational AI chatbot that could answer generic questions and direct more complex questions to a live agent. Further, they implemented tooltips throughout the tax process flow to help users that appeared to be stuck.

Through the RCA process, you might discover that some parts of the user’s experience are confusing and create a plan to address minor UI challenges.